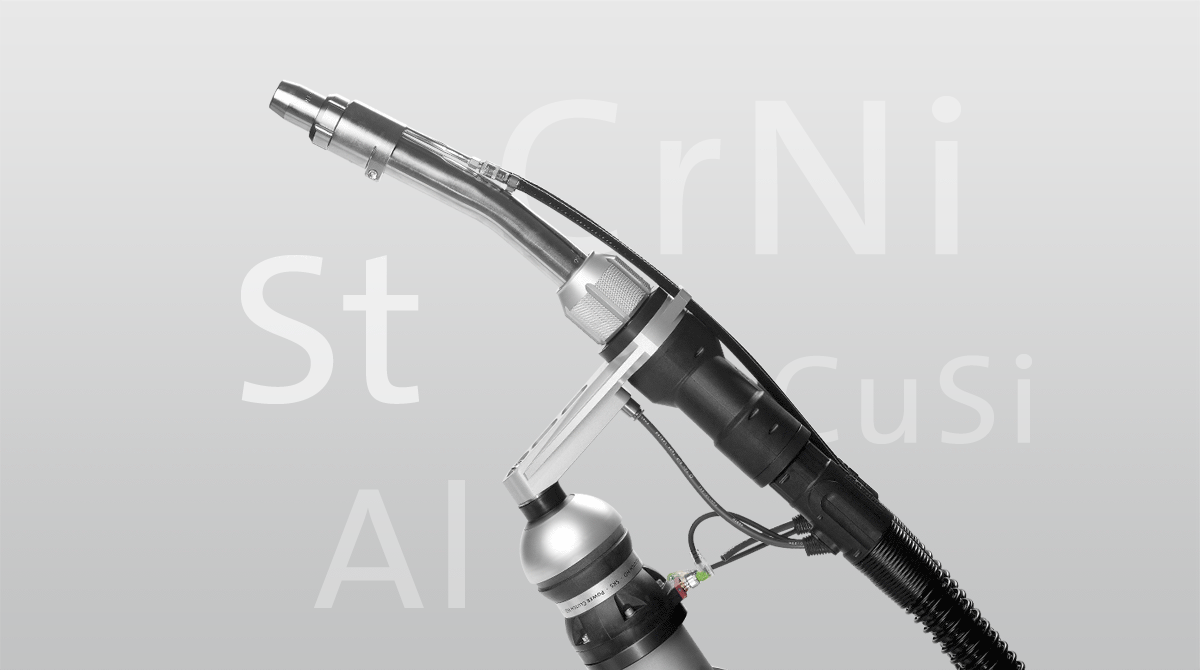

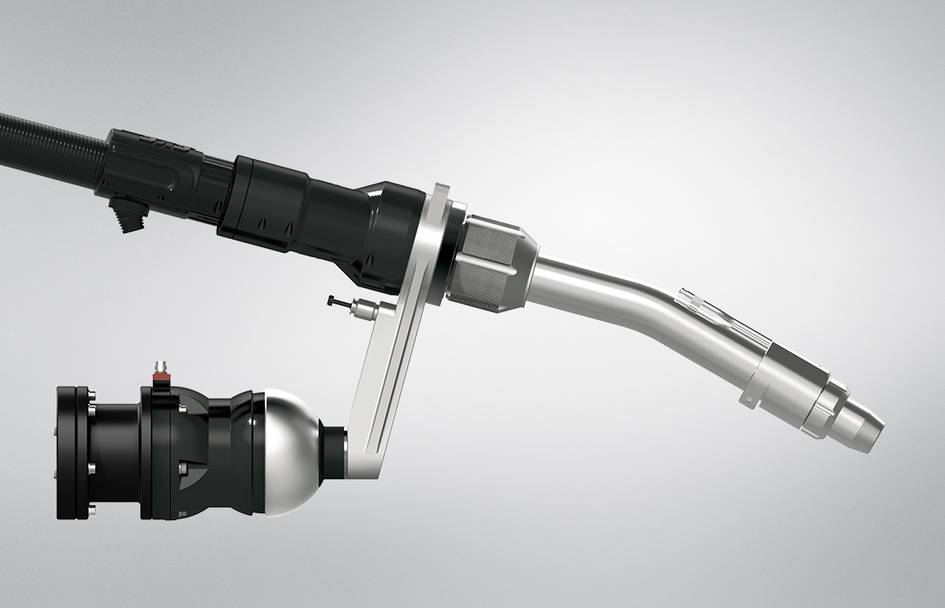

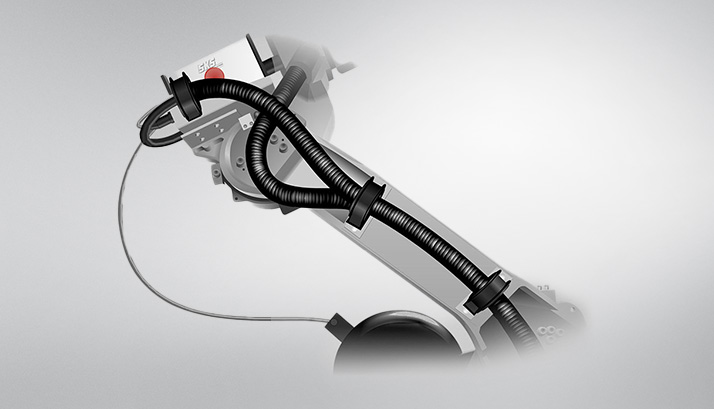

The Dual Wire 2.0 welding torch complements the SKS torch series with its high-performance properties for welding with high deposition rates and/or high welding speeds. Identical to the SKS single-wire torches: The Power Clutch collision protection and the mechanical bayonet connection concept that allows the tool-free exchange of the torch neck – with an accuracy of ± 0.5 mm (Tool Center Point, TCP). In dual wire welding, two wires are melted simultaneously in one weld pool for increased productivity and optimized process times.

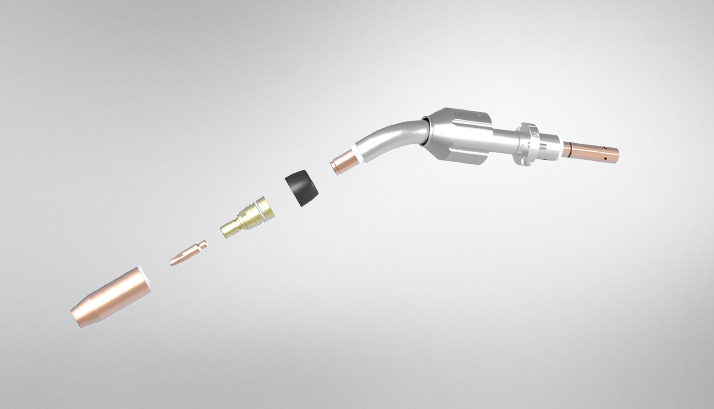

To deliver the necessary energy and the two filler materials to the welding process, two standard SKS torch cables are used to connect to the Dual Wire 2.0 torch holder and neck. The large cross-sections (72 mm²) of the two coaxial torch cables and the contacting in the torch holder optimized with high-current laminations ensure low-loss transmission of the welding current and shielding gas. The round design of the gas nozzle allows very good accessibility even in tight installation spaces and simplifies automatic cleaning of the gas nozzle with conventional torch cleaning equipment.

To cool and dissipate the sometimes very high radiant energy, the Dual Wire 2.0 high-performance torch system has two cooling circuits that effectively protect the torch neck and the wear parts from overheating.