Synchroweld

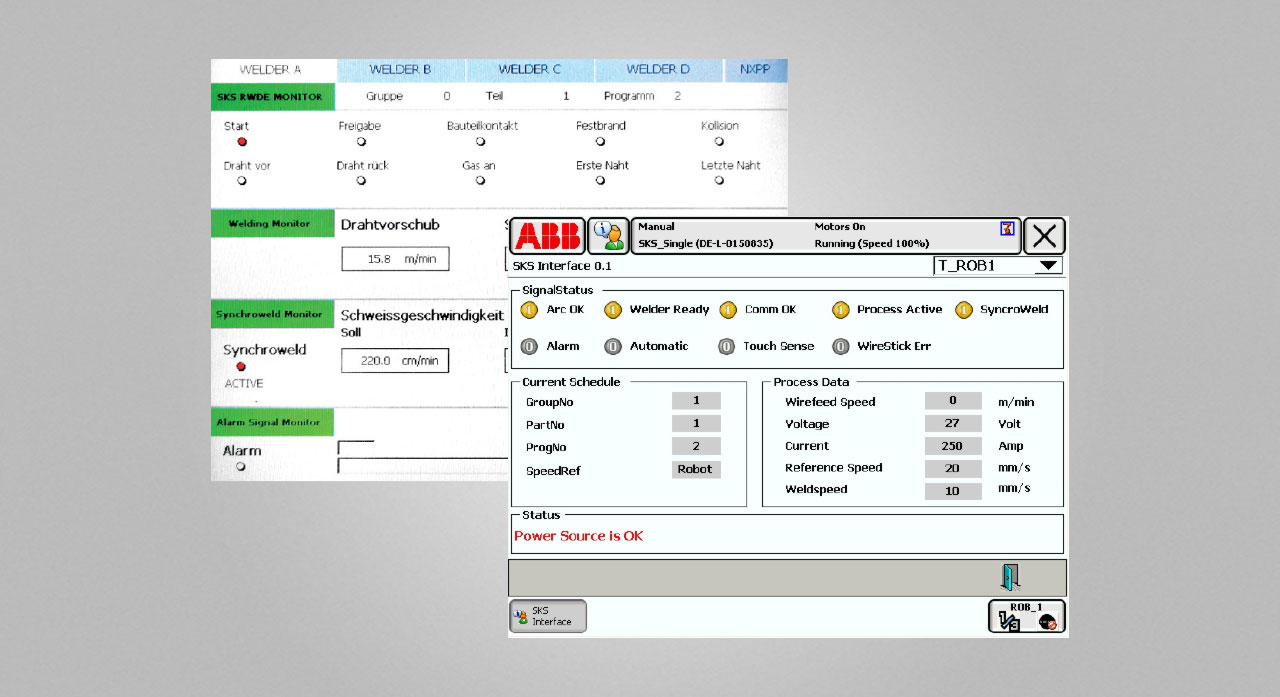

RWDE (Robot Welder Data Exchange)

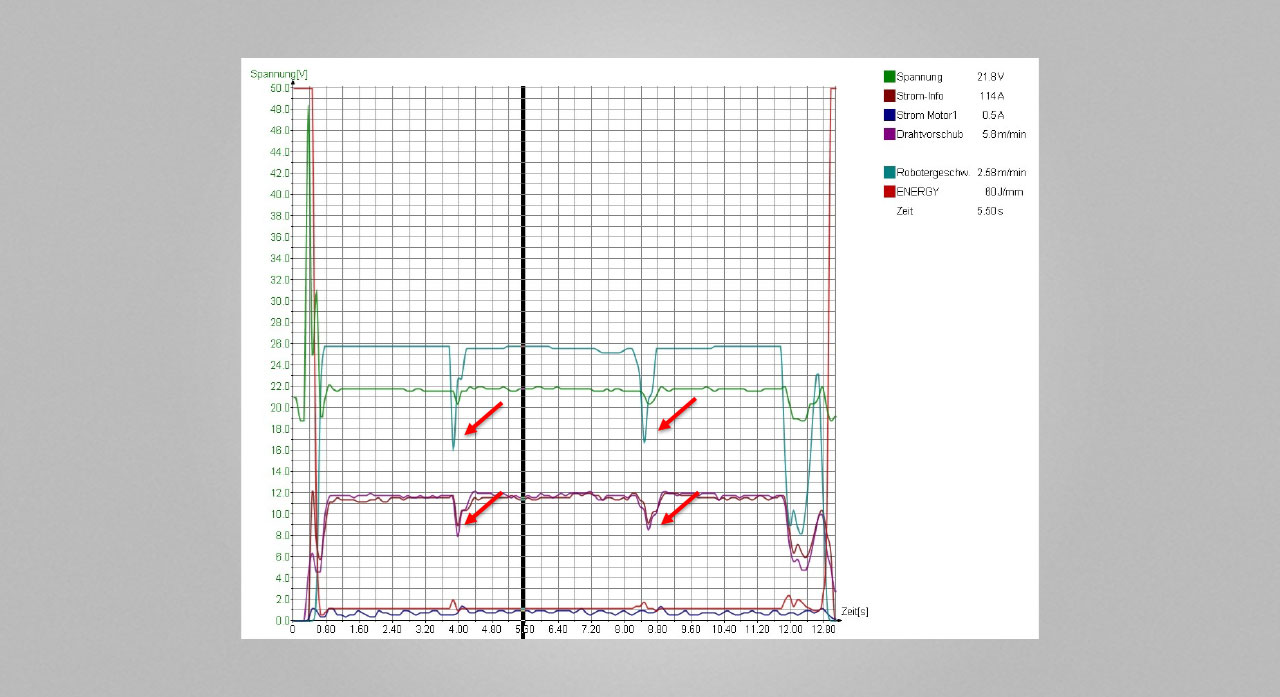

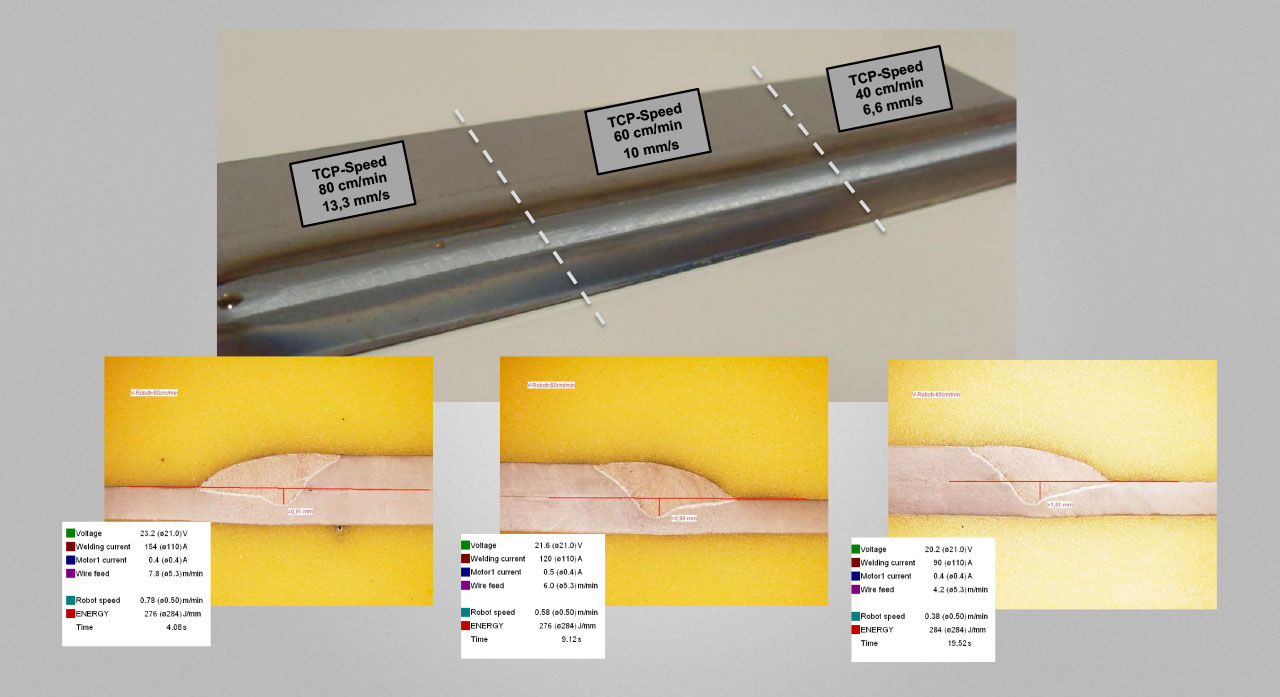

Synchroweld combines the robot and the welding system into a single unit and integrates the welding speed as a control variable into the welding parameters of robot welding systems. The welding control system processes the actual TCP speed of the robot system and adjusts the welding parameters fully automatically to keep the heat input per unit length and thus the welding result constant.

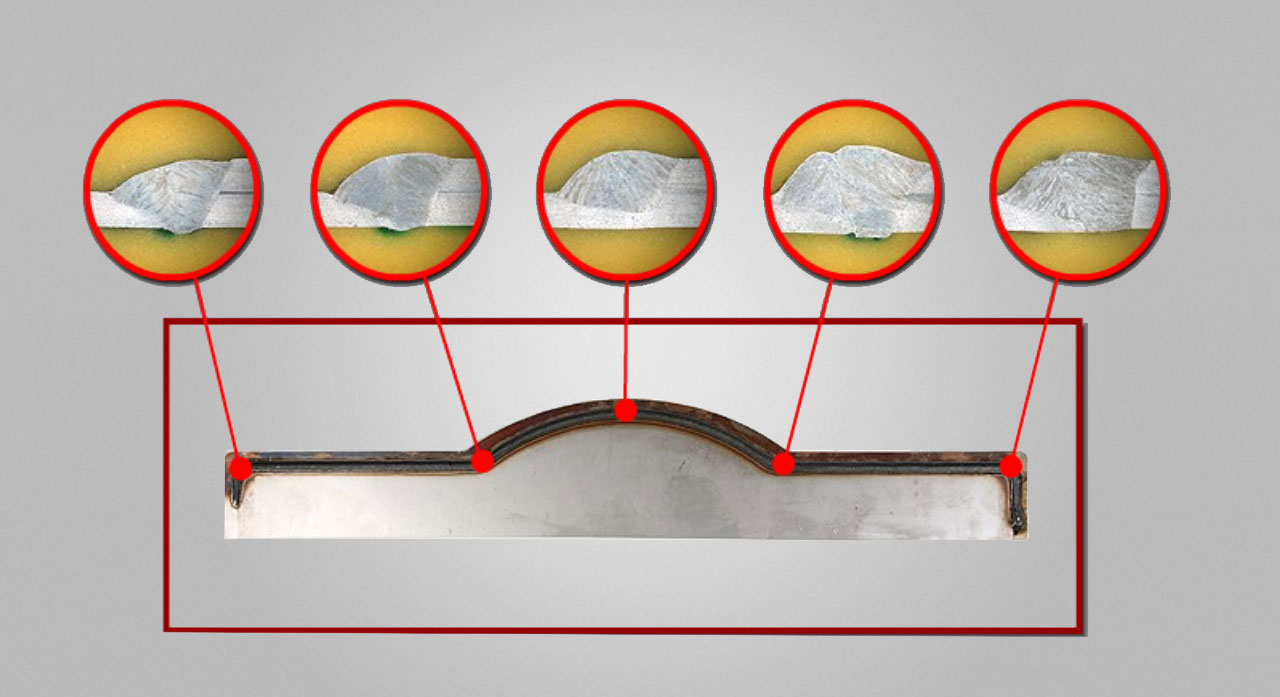

Inadequate programming or tight radii may result in the robot not reaching the programmed TCP speed. In this case, to keep the quality and appearance of the weld seam consistent, all process-relevant welding parameters are then automatically readjusted to the new joining speed by the welding system without manual intervention. The recording of all measured values including the reported robot TCP speed enables the user to optimize the programming of the welding path and also the cycle time.

Special features – Synchroweld

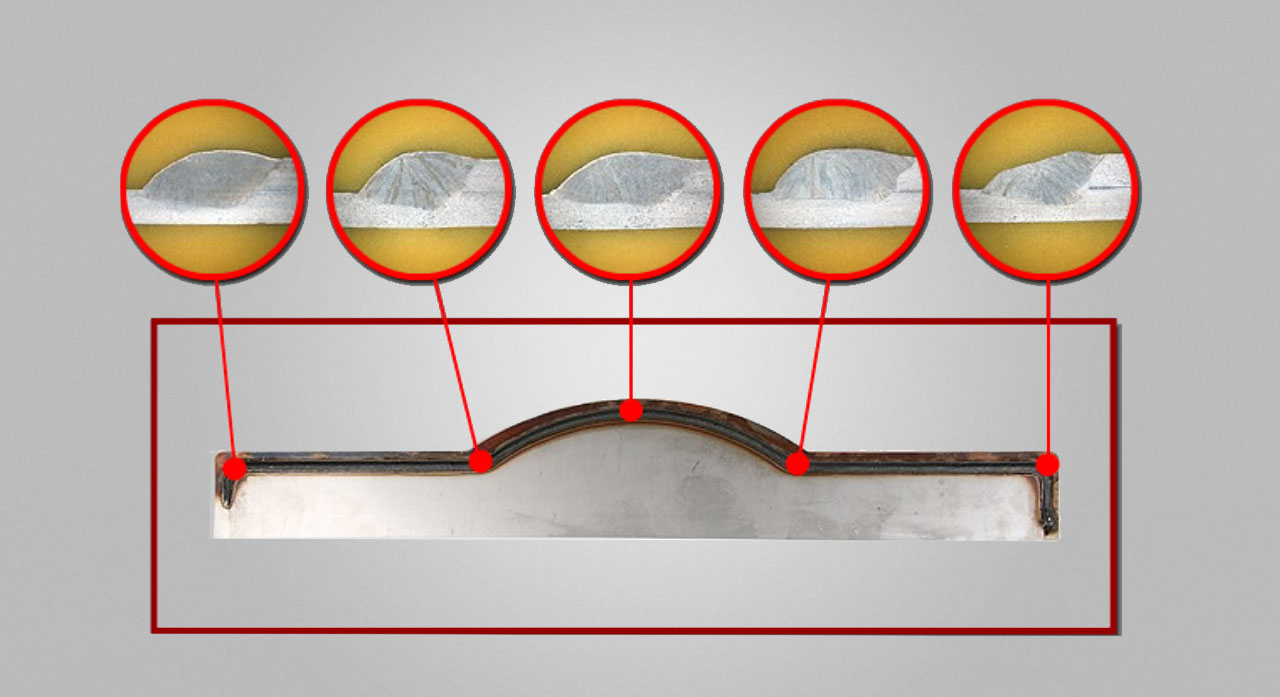

- Optimum welding result: consistent penetration and uniform weld appearance at all points of the weld seam

- Constant heat input: uniform heat input due to constant heat input per unit length

- Process optimization: by visualizing the actual TCP speed in the measured values of the welding system

- Effort and time savings: Especially with complex geometries, the effort for parameter determination and optimization is considerably reduced, therefore fewer workpieces are needed for setup.

- Documentation of welding data: In addition to the set and actual values of the welding system, the robot TCP speeds are recorded.

- RWDE Monitor: The new data interface allows all relevant process data to be displayed on special screens of the robot programming device.

The robot speed is not processed by conventional welding equipment, i.e. changes to the robot speed always require manual parameter adjustments to the welding device in order to achieve a consistent welding result.

With Synchroweld, the welding parameters are automatically adjusted to the actual robot speed. The heat input per unit length or the deposition rate and the penetration remain virtually constant. No manual intervention is required.

SKS Weld Packages

This might also interest you