SKS welding data recording:

Network Welder Data Exchange (NWDE)

The direct visualization and processing of process data is becoming increasingly important in industrial production. Fast access to specific, pre-evaluated information effectively supports the individual departments in their tasks, workflows become more efficient, and the tracing and optimization of individual process steps becomes significantly easier. Since this added value was recognized by SKS early on, the networking of weld controllers and the documentation of process data have been part of the SKS welding equipment for many years.

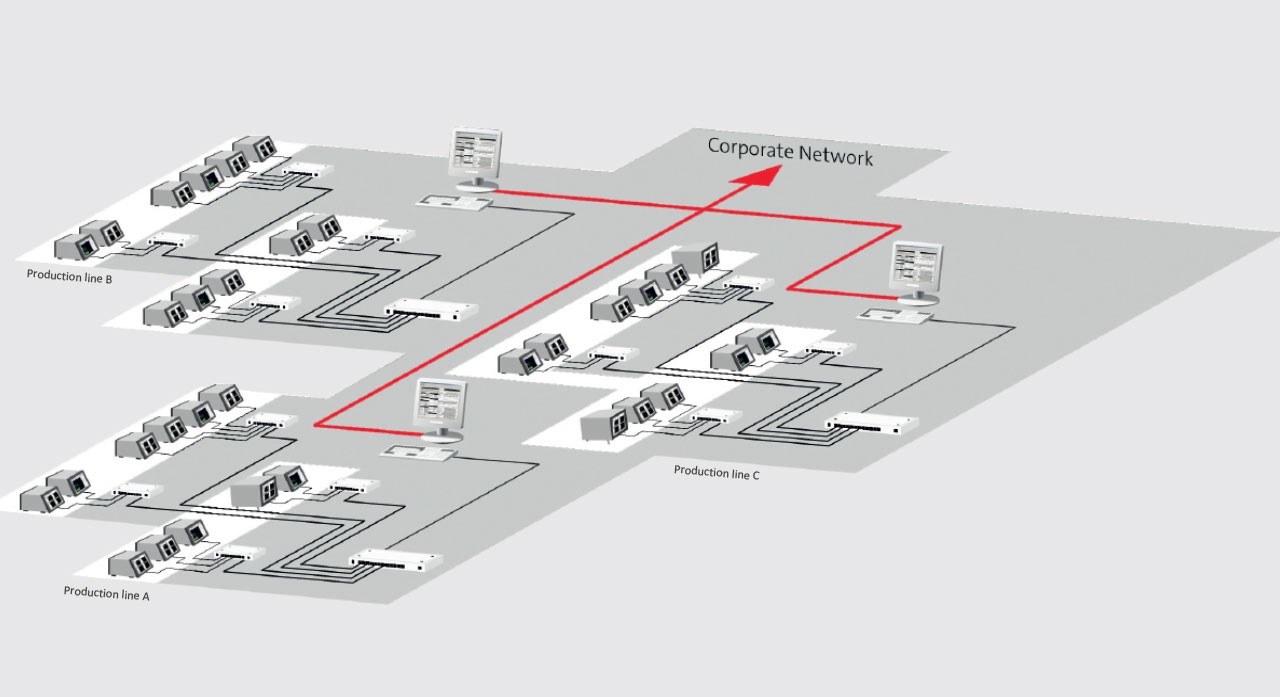

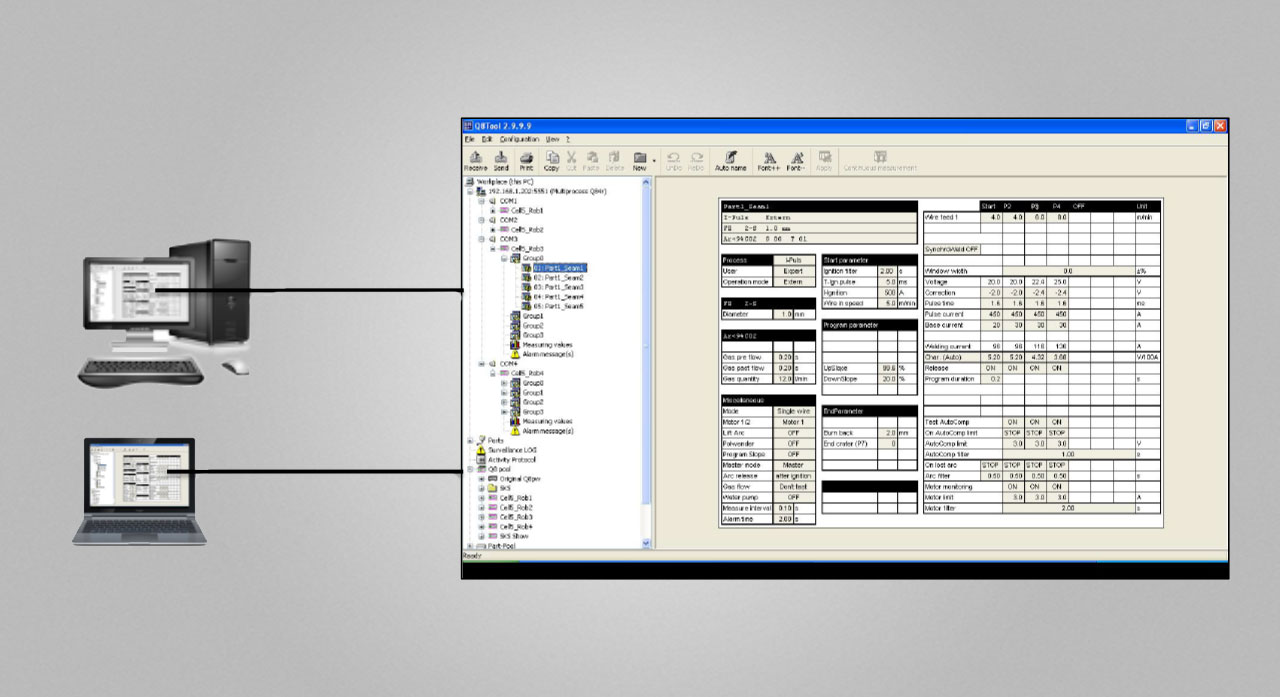

The Q8 welding process controllers and the powerful Q8Tool software serve as the central unit for managing all information relating to the welding process. Communication to a PC system or a network can be established easily via an existing LAN connection on site. The tracing and allocation of welding process data to a workpiece or assembly can also be implemented cost-effectively by automatically combining all information and a workpiece ID. Via a standardized interface, the machine data can be transferred live to a higher-level system, where it can be further processed and prepared for specific users.

SKS Q8 network

- For quick and easy networking, each Q8 controller features a LAN connection.

- Access to, display or change of process parameters via network or directly via laptop

- User authentication via Windows user account

- Enormous time savings – no long ways, remote management with Q8Tool

SKS Q8Tool software

- Administration of weld process controllers and process parameters via PC or laptop

- Online and offline management of process parameters

- Record and save measured values

- Same graphical user interface as Q8 weld process controller

- Easy export of data

- Free of charge for customers (no additional costs)

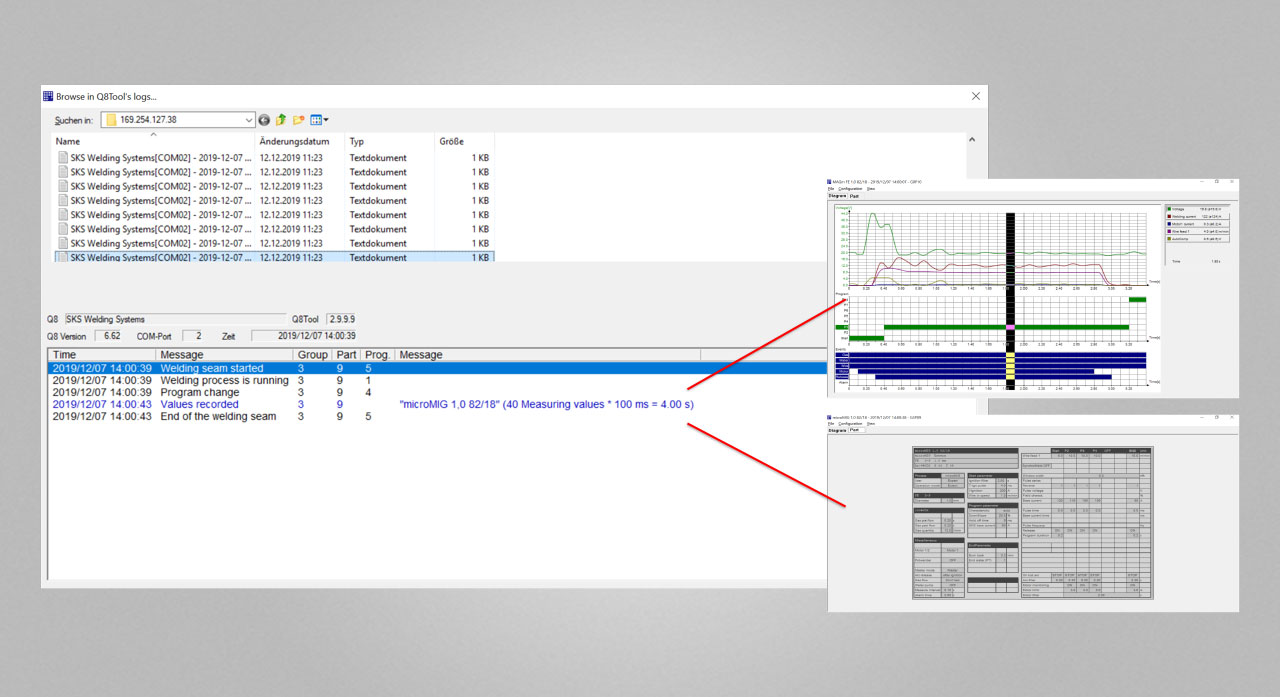

SKS Q8Logging: automatic data acquisition

- Automatic recording and storage of all process data

- Viewer functions for displaying the current status, alarm messages, and all recorded data (setpoints, measured values, alarm messages, date-time stamp)

- Tracking of parameter changes

- Traceability option: Implementation of a component ID (reading of the component ID from PLC)

- Easy export of data

- Q8Tool standard function – no additional costs

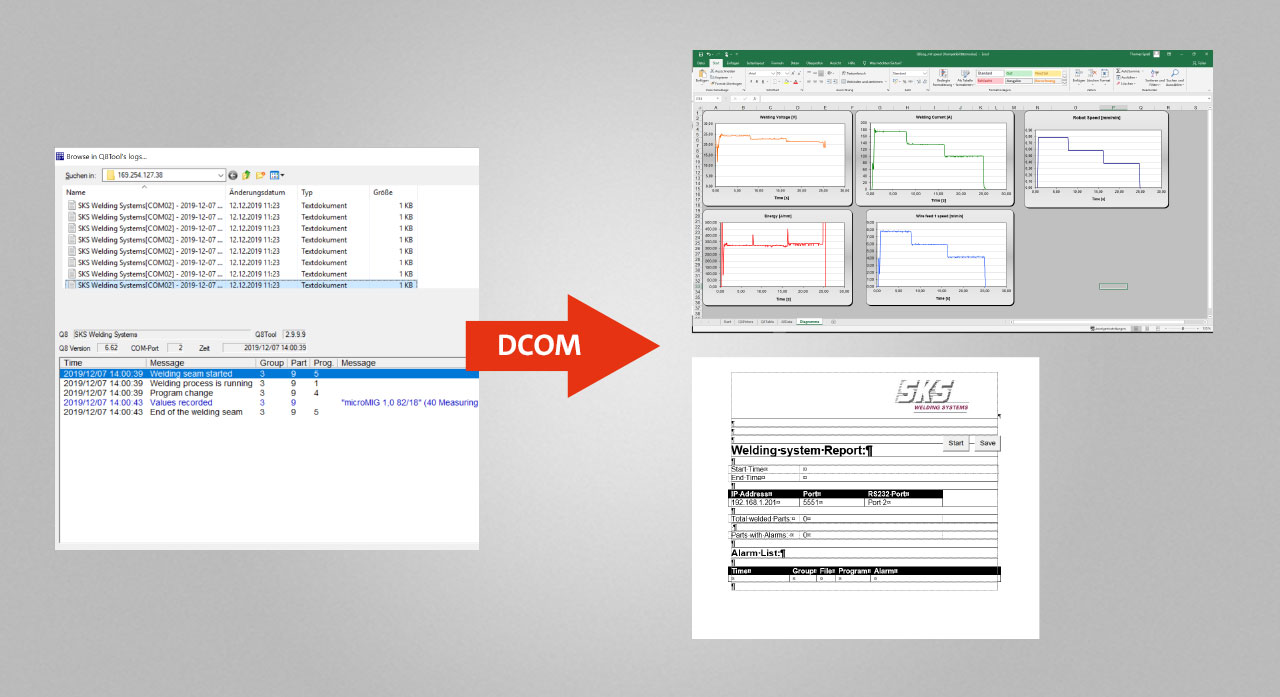

SKS DCOM interface

- Live transmission of recorded process data to higher-level quality management system

- Process data can be prepared automatically, e.g. by means of Excel or Word

- Visualization of prepared data in user-specific diagrams and reports

- Online analysis for fast reaction in case of malfunctions

SKS Weld Packages

This might also interest you