Welding Processes

To provide solutions for current, but also new and future tasks, the SKS welding system offers different welding process variants and system functions. When selecting suitable welding equipment and process variants, SKS supports its customers with comprehensive and expert advice on site and with welding tests in its in-house robot laboratories. The quest for the best solution is always a priority for the process specialists at SKS. In addition to the actual requirements of the workpiece to be welded, production-specific boundary conditions are always included in their considerations.

Supplementary production-related feasibility analyses on samples or pre-series parts show the feasibility and possible potential for improvement, so that further optimizations can be carried out, e.g., concerning the preparation of individual parts. Recommendations for filler materials, shielding gases, torch and workpiece positions as well as a detailed documentation of the test setup allow an easy transfer to series production. The result of all this should always be the selection of the simplest and most suitable welding process that meets all the qualitative and economic requirements of the joining task.

Application:

Welding Processes

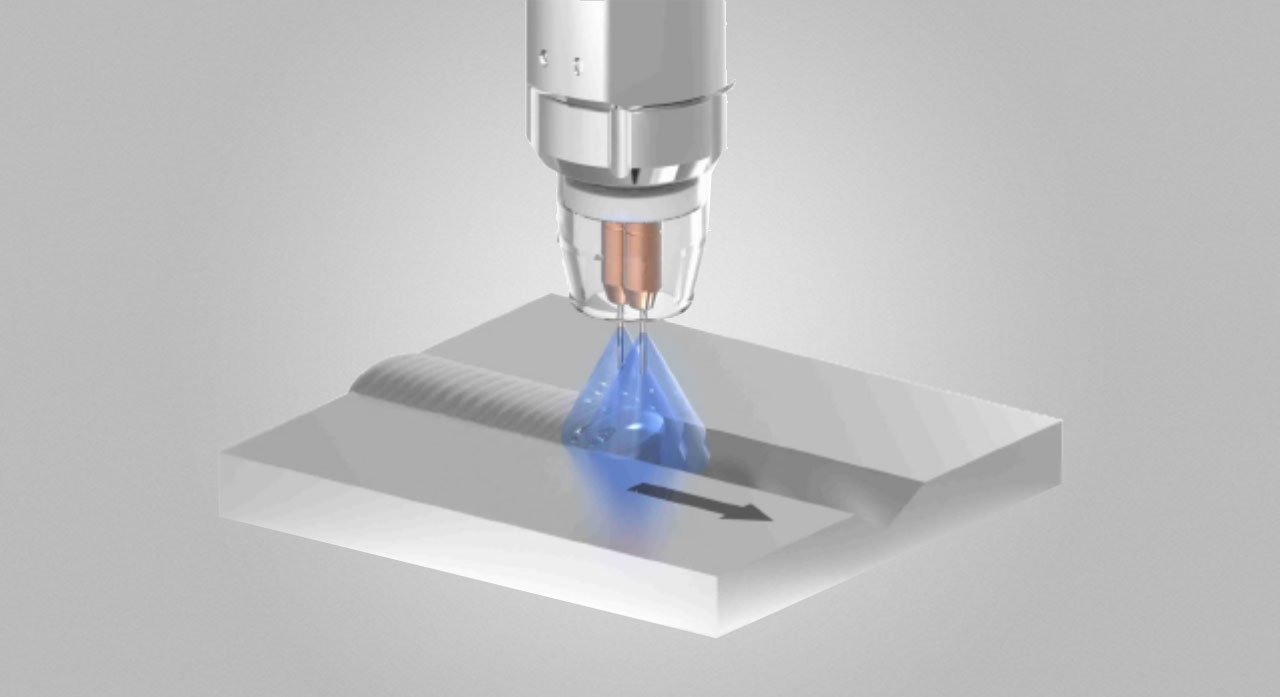

Depending on the torch system used, SKS welding equipment provides a range of different welding processes. Most welding processes and special functions are supported by all torch systems, only the heat-reduced microMIG processes and the Dual-Wire process require special torch components. Retrofitting is possible at any time, as the main components are prepared for all welding processes and no additional costs for further software options have to be calculated.

Each welding process has its own special properties and possible applications. In combination with different shielding gases and filler materials it is thus always possible to find the best solution for the respective application.