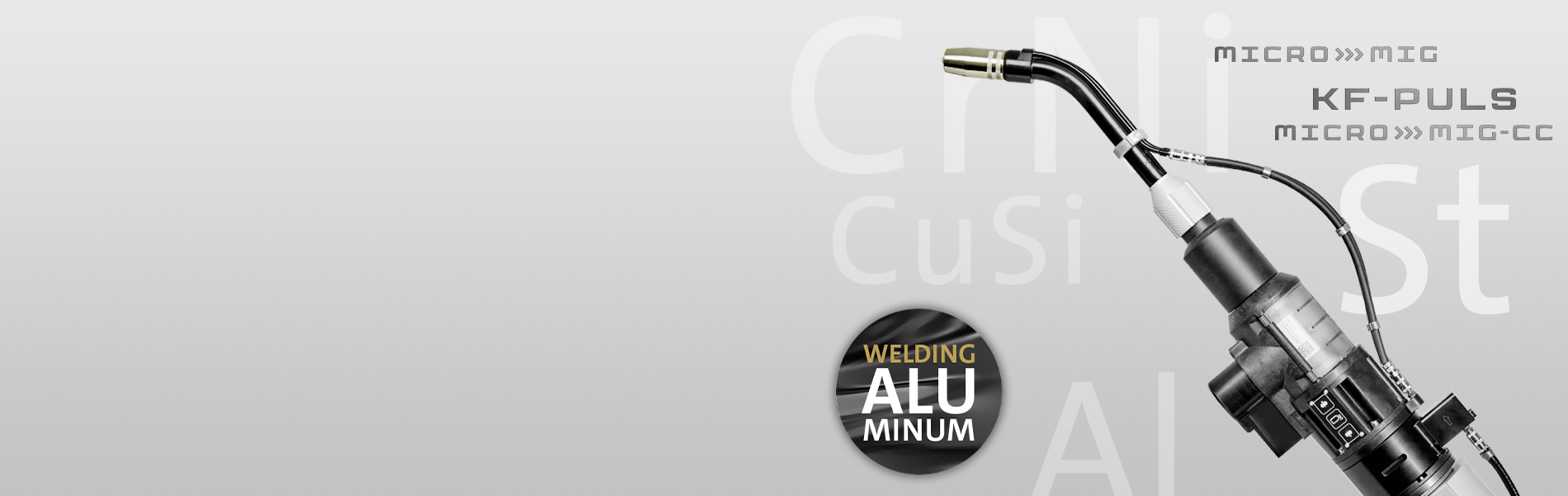

Frontpull 8i water-cooled:

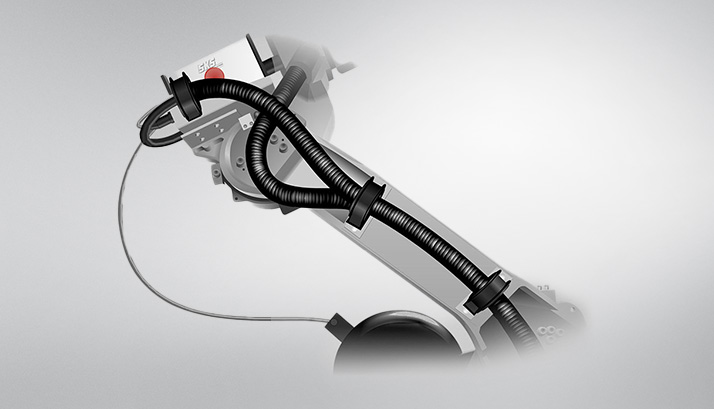

Highest precision with unprecedented freedom of movement: For all industrial robots with inner cable dress

Just as the air-cooled “Frontpull 8i”, the water-cooled “Frontpull 8i water-cooled” also perfectly masters the interaction of welding systems and robots with inner cable dress. The Frontpull 8i water-cooled features the same design-based benefits and characteristics as the air-cooled version of the welding torch: The rotating joint (infinitely rotatable in both directions - i.e. unlimited rotation beyond 360 degrees), the wire feed unit integrated in the torch system for highest precision directly at the process, and the integrated collision detection – to name but a few.

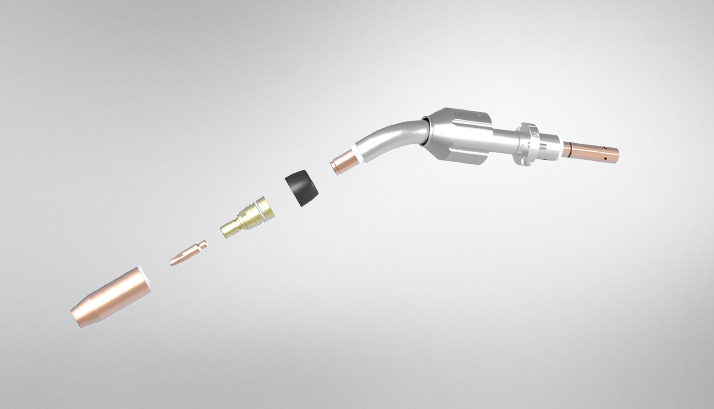

The air-cooled version of the Frontpull 8i can be converted to the Frontpull 8i water-cooled with the addition of a water cooling system to further extend its range of applications. The reflected is reliably dissipated via an additional heat dissipation to increase the service life of the torch system’s wear parts. While standard water-cooled welding torches co-cool the torch neck and the torch cable, SKS takes a different approach with their water-cooled welding torch systems. Due to the design-related properties of SKS torch necks and the material mix used, the heat only has to be dissipated from the gas nozzle. For this purpose, SKS have developed a special heat sink for their single-wire torch systems, which is liquid-cooled and cools the gas nozzle using two external cooling hoses. The main advantages of the air-cooled torch systems are retained.

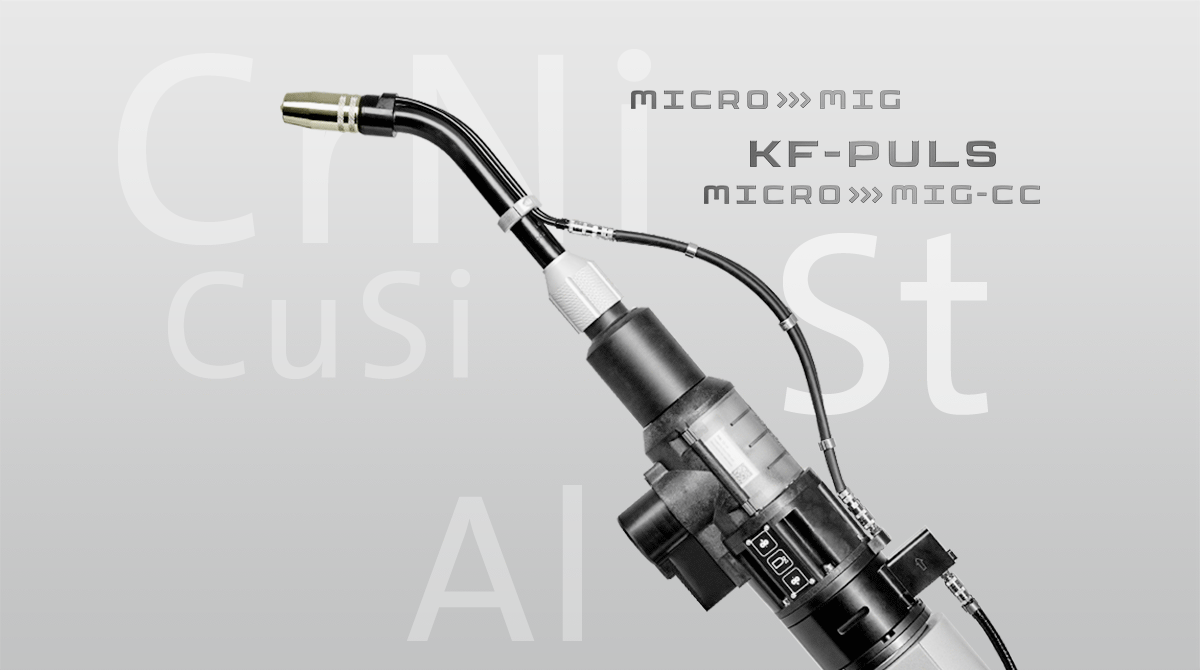

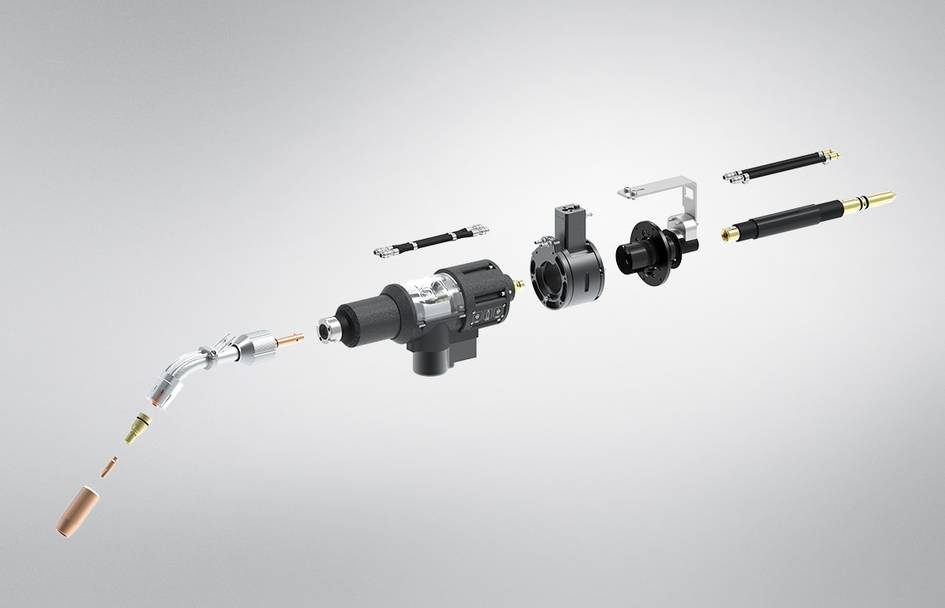

Water Joint Module and assembly kit for Frontpull 8i water-cooled

The Water Joint Module is an additional component for all water-cooled SKS welding torches designed for robots with internal torch cables. The Water Joint Module extends the torch system by adding the function of unlimited rotation beyond 360 degrees with water cooling. The assembly kit includes locking cover, connecting flange, clamping sleeve, sealing sleeve, and mounting accessories for the different robot types