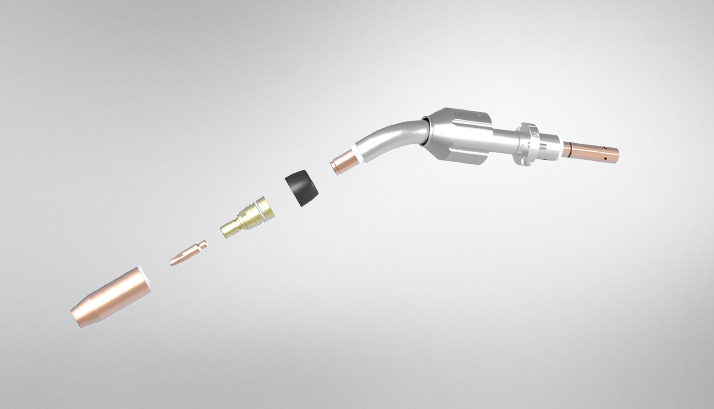

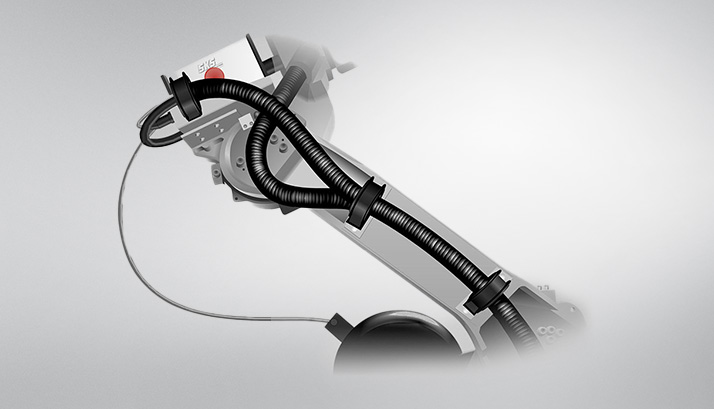

Cobots excel in executing repetitive tasks with precision, making them ideal for welding applications requiring consistent quality. Equipped with our welding equipment, especially with our Frontpull Technology, cobots support our state-of-the art functions/processes we use in non-cobot robotic arc welding.

Our extraordinary reliable welding torch systems with our benchmarked PF5 wire feeder are perfectsuited for cobotic applications. To optimize costs for better efficiency we have developed two new process controllers, integrated into the power source. LSQ Compact Lite focuses on cost optimization. It is designed to maximize cost efficiency, thereby reducing operating costs. LSQ Compact IoT offers additional functions such as Internet of Things (IoT), MQTT and OPC UA is supported. This advanced controller enables real-time monitoring and analysis of welding processes, resulting in improved quality assurance and more precise control of the process. Both are available with LSQ 3 and LSQ 5 power sources for having the best powered solution for you application:

LSQ5/LSQ3 COMPACT Lite

LSQ5/LSQ3 COMPACT IoT