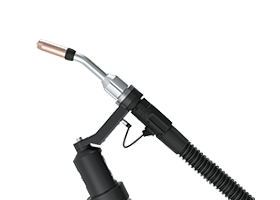

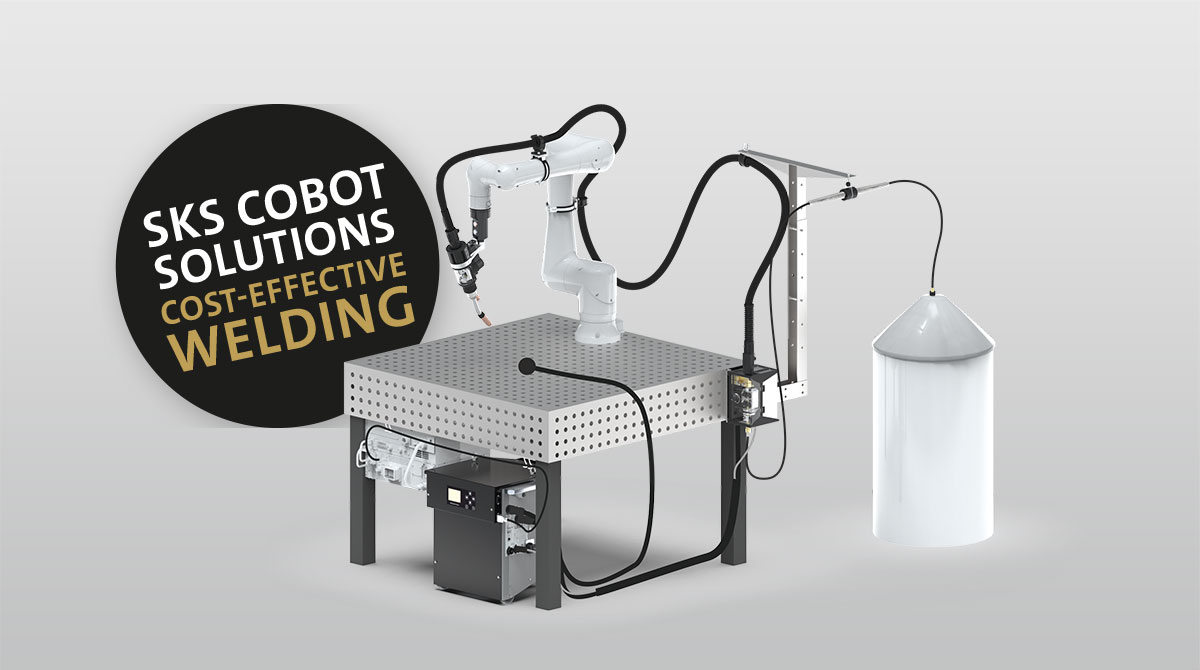

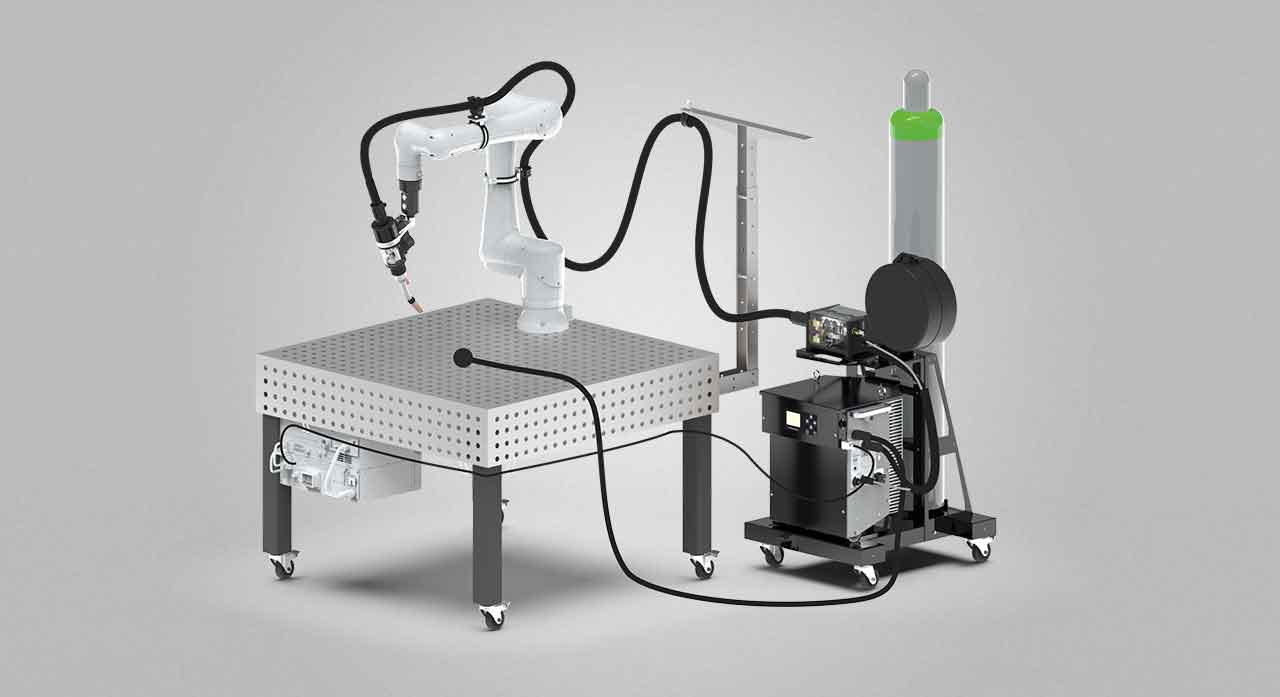

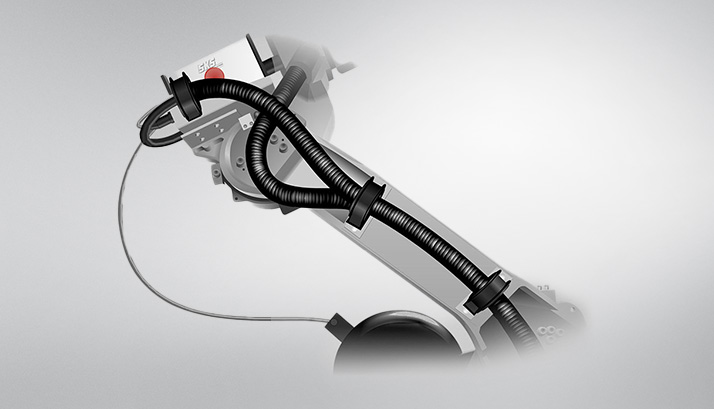

Cobots are easy to use and excel in executing repetitive tasks with precision, making them ideal for welding applications requiring consistent quality. Equipped with our welding equipment, especially with our Frontpull Technology, cobots support our state-of-the art functions/processes we use in non-cobot robotic arc welding.

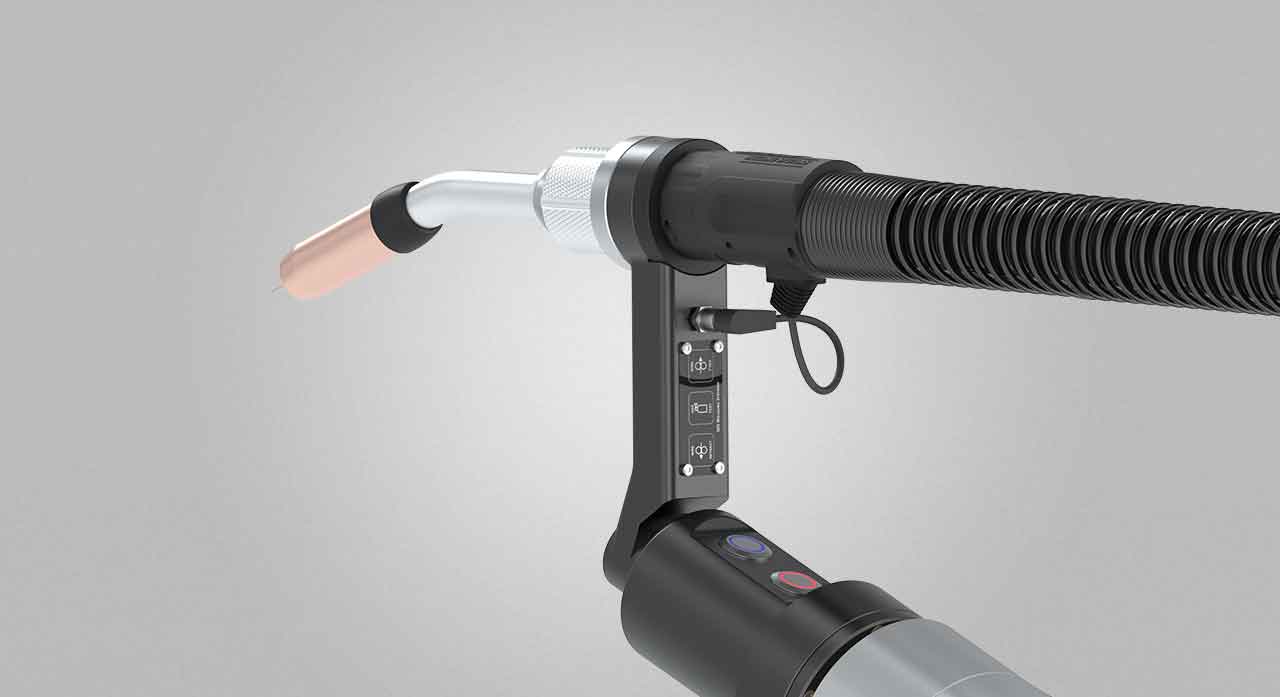

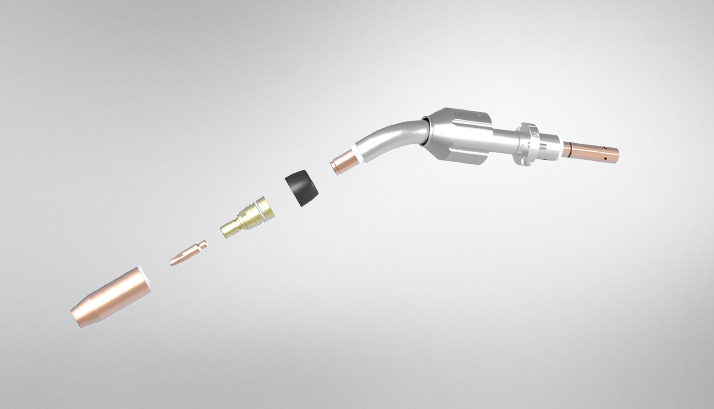

Our exceptionally reliable welding torch systems with our proven PF6 wire feeder are the ideal choice for cobot applications. To reduce costs for higher efficiency, we have developed two new process controllers integrated into the power source. Additionally, a fieldbus interface has been integrated into the power source. To cover as many application areas as possible, we provide two types of LSQ COMPACT Power Sources: LSQ COMPACT Lite and LSQ COMPACT IoT. While the LSQ COMPACT Lite is designed for maximum cost efficiency, the LSQ COMPACT IoT offers additional features such as the Internet of Things (IoT), MQTT, and OPC UA support. This advanced weld process controller enables extended real-time monitoring and analysis of welding processes, resulting in improved quality assurance and more precise control of the process. Both are available with LSQ 3 and LSQ 5 power sources to provide the best solution for your application. Cobots with SKS welding equipment are the perfect start to get into robotic arc welding.