EGR cooler:

High-alloy steel

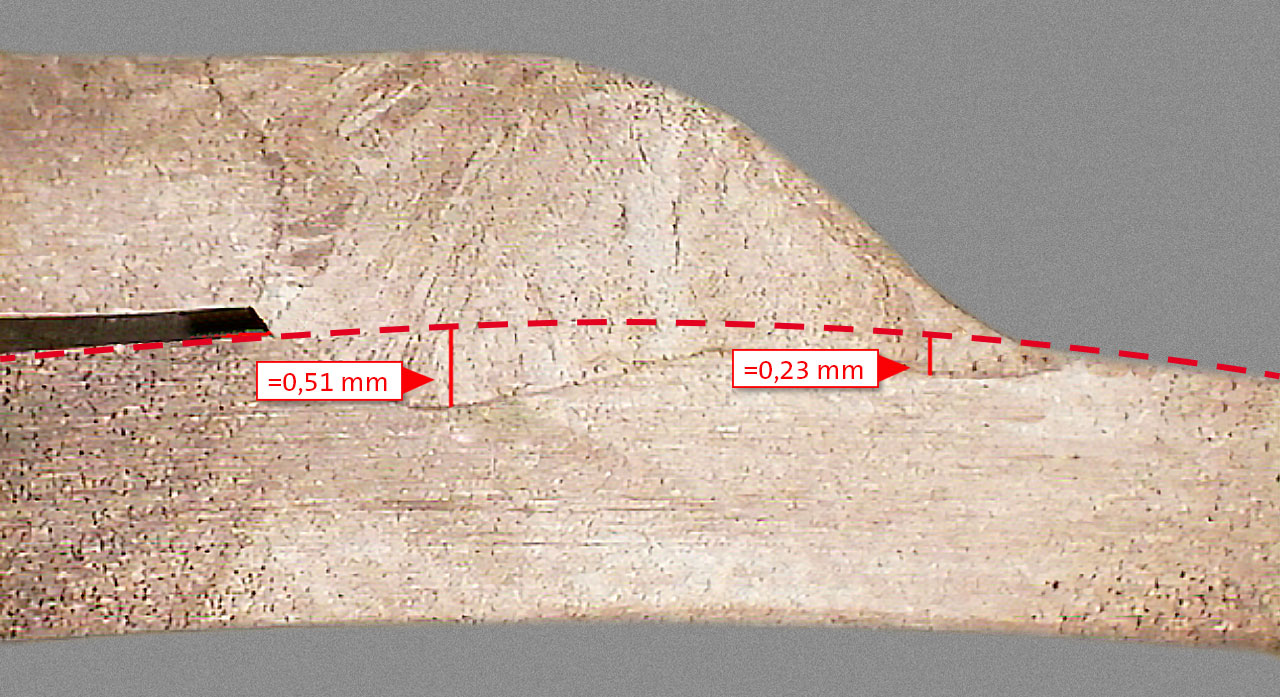

Lap weld | |

|---|---|

| Welding process: | KF-pulse |

| Welding speed: | 120 cm/min |

| Heat input per unit length: | 148 J/mm |

| Base material 1: | 1.4301 (X5CrNi18-10) 1.5 mm |

| Base material 2: | 1.4301 (X5CrNi18-10) 1.5 mm |

| Filler material: | 1.4316 (ER 308 LSi) 0.8 mm |

| Shielding gas: | 98 % Ar -2 % CO2 |

Special features – EGR cooler

- excellent weld appearance

- no spatter

- good gap bridging