System Function DP-Basic:

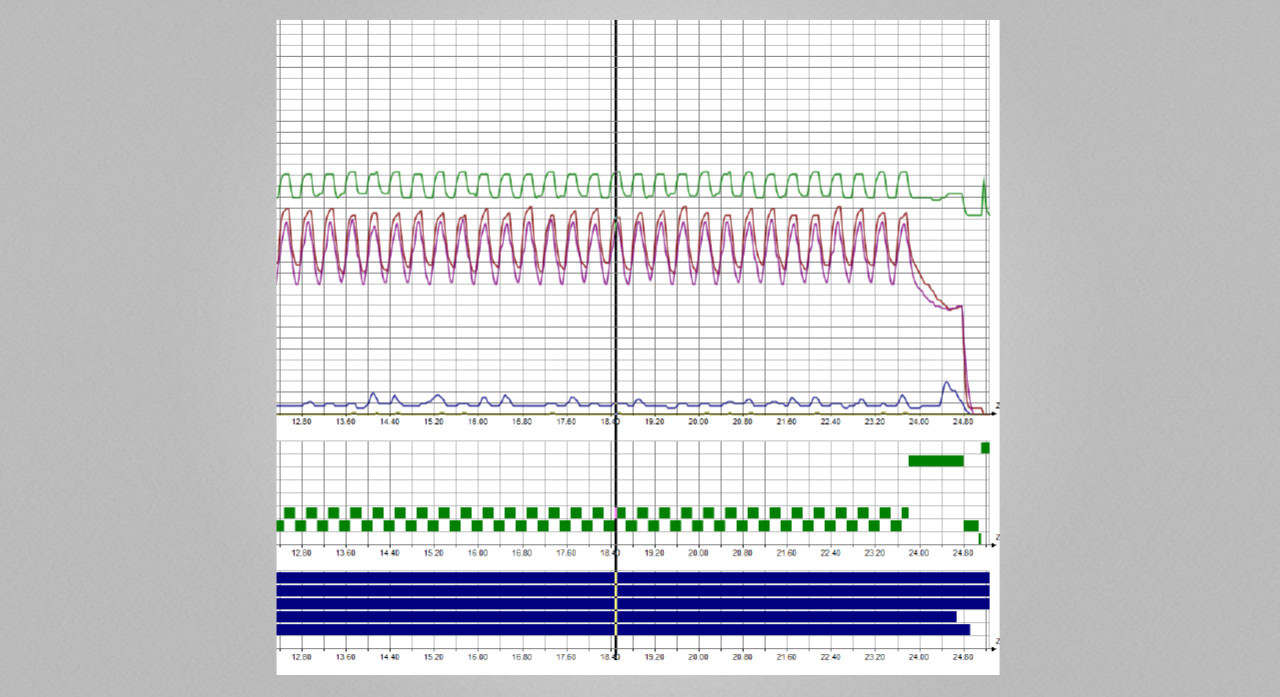

Special setup for cyclic parameter changes

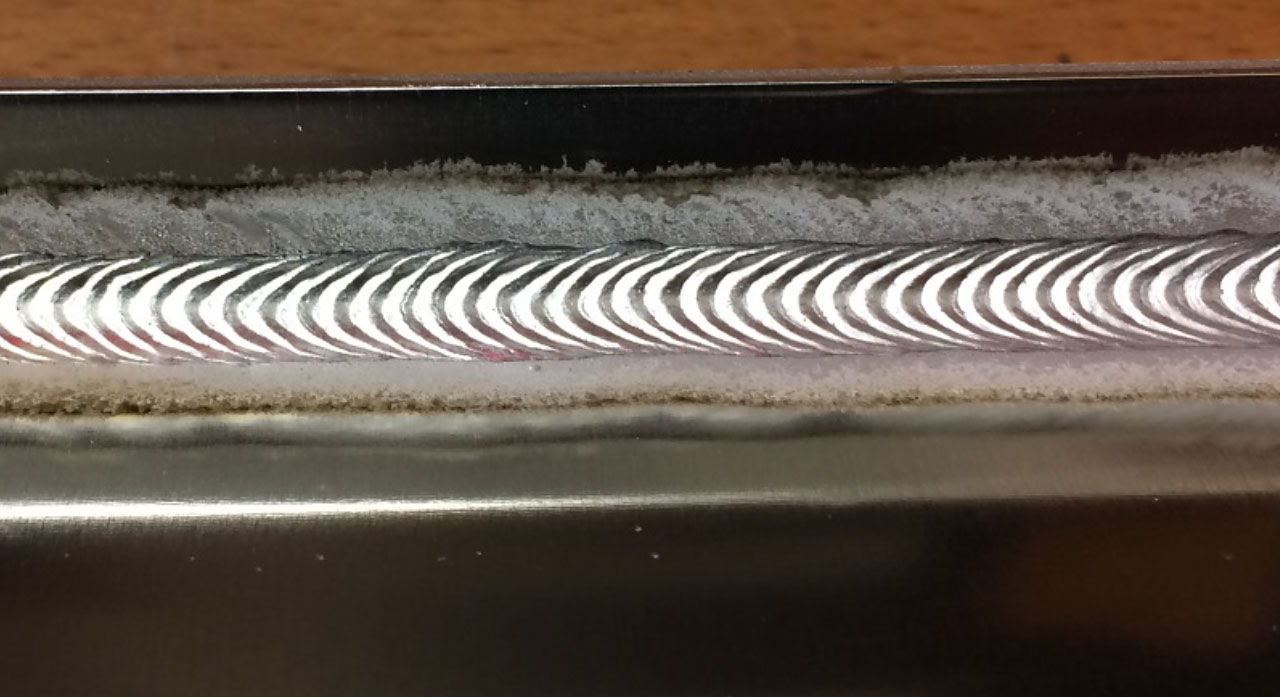

A periodic alternation between two different wire feed speeds produces a swelling and shrinking of the weld pool. The controlled alternating of the power ranges is used for targeted heat control and enables better gap bridging. In addition, the formation of pores can be reduced when welding aluminum materials. The evenly rippled weld surface meets the high visual demands of visible seams.

Special features – DP-Basic

- better heat control

- excellent gap bridging

- creates evenly rippled weld surface

- better flow of the weld pool

- reduction of pores

- also suitable for thin materials

- works with all SKS welding processes

- frequency up to 5 Hz

- setting grid: 0.1s steps

- both parameters independently adjustable

DP-Basic and microMIG / microMIG-cc

The DP-Basic function is also available with the heat-reduced microMIG processes. The cyclic change of the transition types with and without an intermediate pulse opens up further application possibilities. The bridging of very large joint gaps is another advantage.

Advantages DP-Basic

- excellent heat control

- suitable for thin aluminum materials

- excellent gap bridging

- coarse scaled seam appearance

Aluminum welding with DP-Basic and microMIG / microMIG-cc combined

Application example – lap weld

AlMg3 2.0 mm

microMIG + DP-Basic

V = 80 cm/min

gap 2.0 mm

This might also interest you