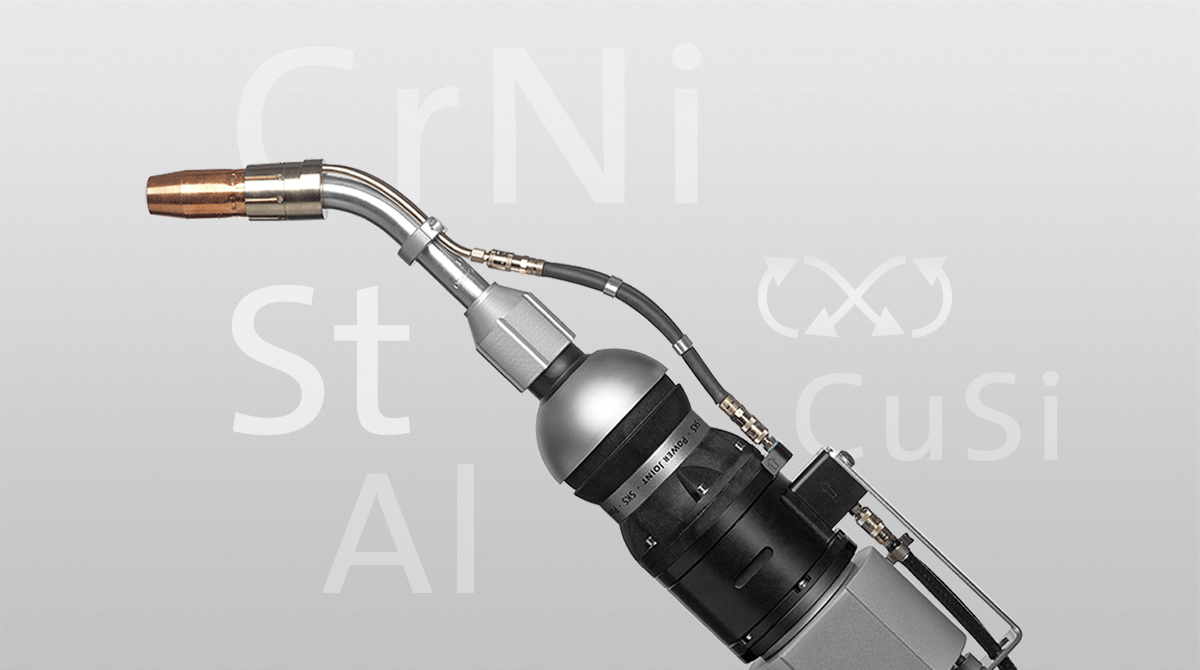

With some welding tasks, additional cooling is required to increase the service life of the wearing parts. For applications with higher-than-average switch-on times and very high amounts of reflected heat, SKS developed the Water Joint, Water Joint Lite and Power Clutch water-cooled torch systems.

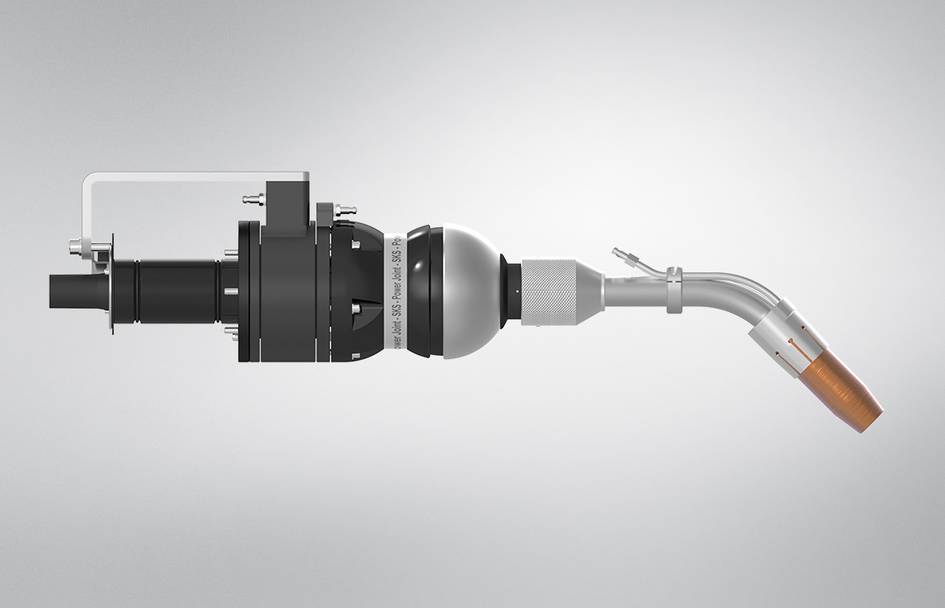

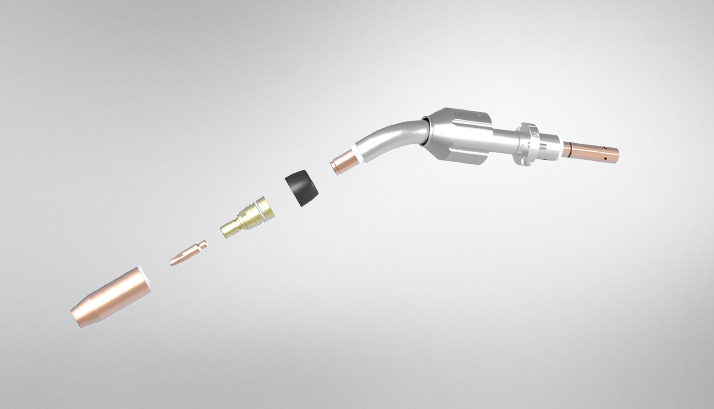

While traditional water-cooled systems cool the torch neck and torch cable, SKS chose a different approach. To increase heat dissipation, a special heat sink has been developed that cools only the torch neck and the wear parts with water. The advantages of the slim design and the large cable cross-sections of the air-cooled SKS torch systems are also found in the Water Joint.

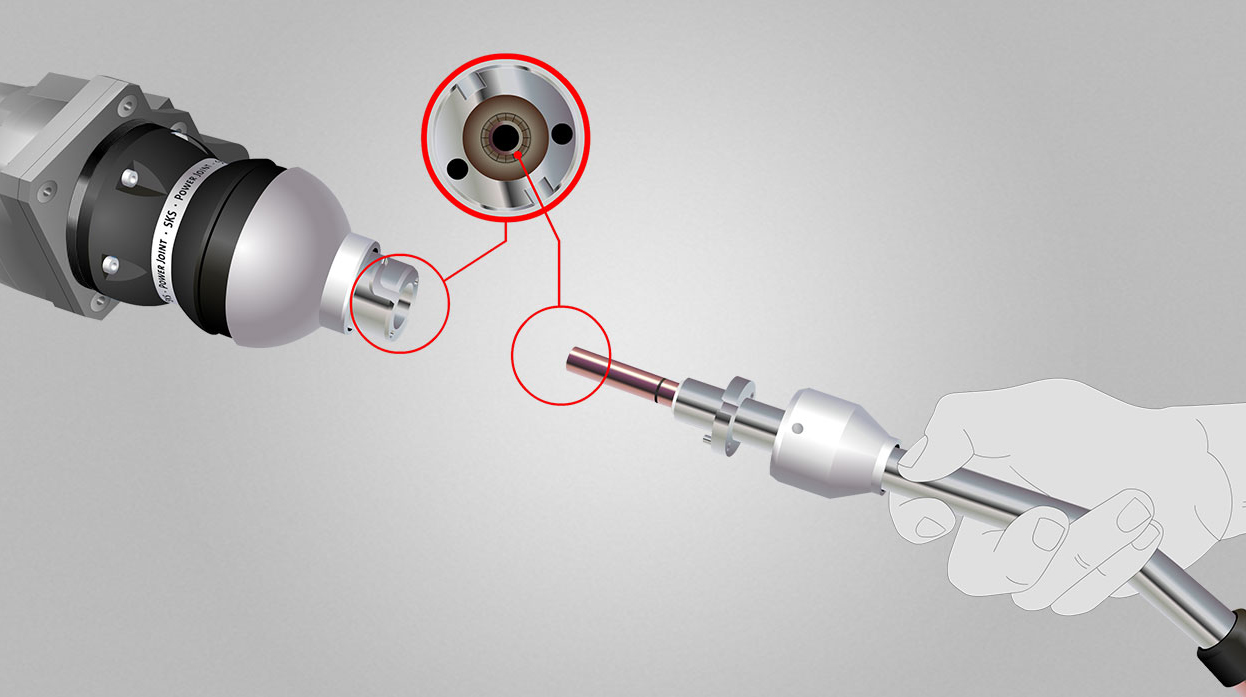

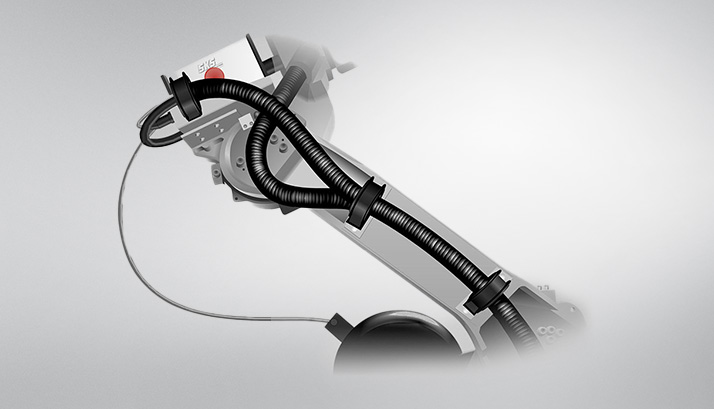

The Water Joint torch system perfects the interaction between welding systems and robots with an internal torch cable. The Power Joint's rotary coupling, which has proven itself thousands of times, is supplemented in the Water Joint by a water coupling that also features endless rotation and thus also all the advantages of the decoupled torch cable. In addition to welding current, shielding gas, air and wire, the rotary joint also transmits the cooling water.

The innovative water-cooled torch system helps the robot to make full use of its freedom of movement. Time-consuming reversing of the hand axis or limitations of the articulation axis are a thing of the past, the robot can reach any point by the shortest possible path.