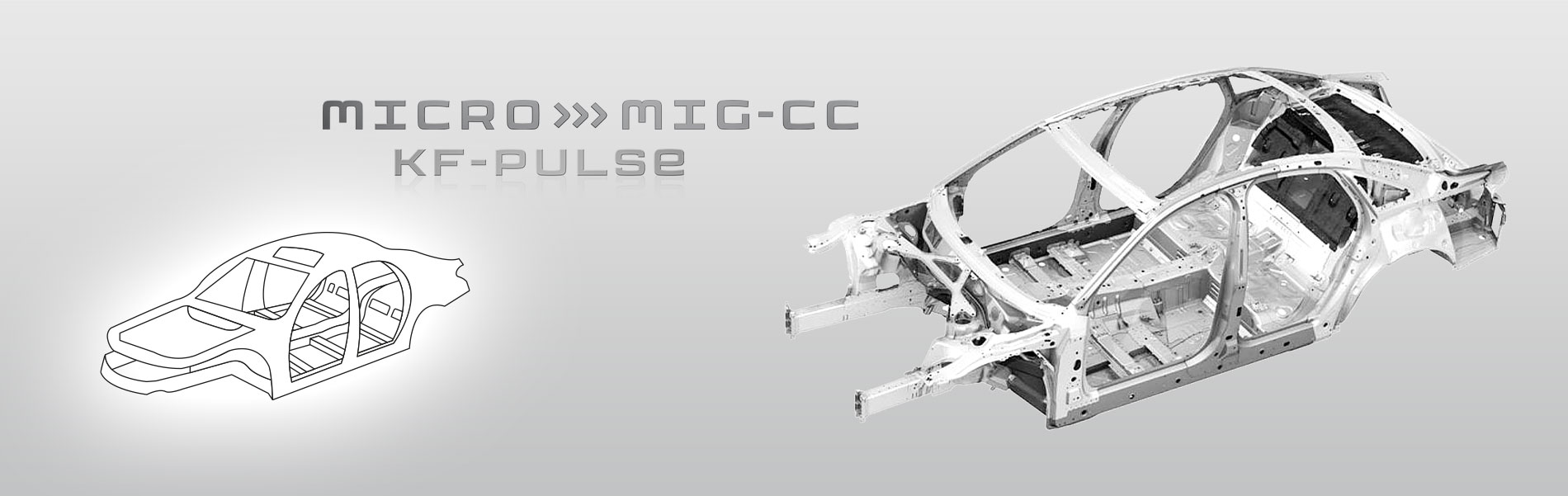

Car Bodies

Many different joining methods are used in car body construction. In addition to the well-tried spot welding, the share of arc welding and brazing joints is steadily increasing.

Due to the size of the components, industrial robots with long ranges are used in interlinked transfer systems. These require a very flexible system design and maximum availability of the individual systems, as a failure or stop would interrupt the entire production.

The many different base materials and surface coatings, the sometimes large positional tolerances and the resulting air gaps (between the sheets) make the joining tasks even more difficult.

SKS has been successfully meeting these challenges for years.

Welding challenges

- different base material combinations

- various surface coatings

- different material thickness combinations

- air gaps / trim and position tolerances

- soiled surfaces and spaces between components (glue)

- different joining methods (welding / brazing)

- various weld fillers and shielding gases

Prerequisites

- flexible system configuration

- optimized / close-to-process wire feeding

- precise heat control / heat-reduced welding processes

- reproducible welding processes / welding parameters

- variable use of different joining methods / processes

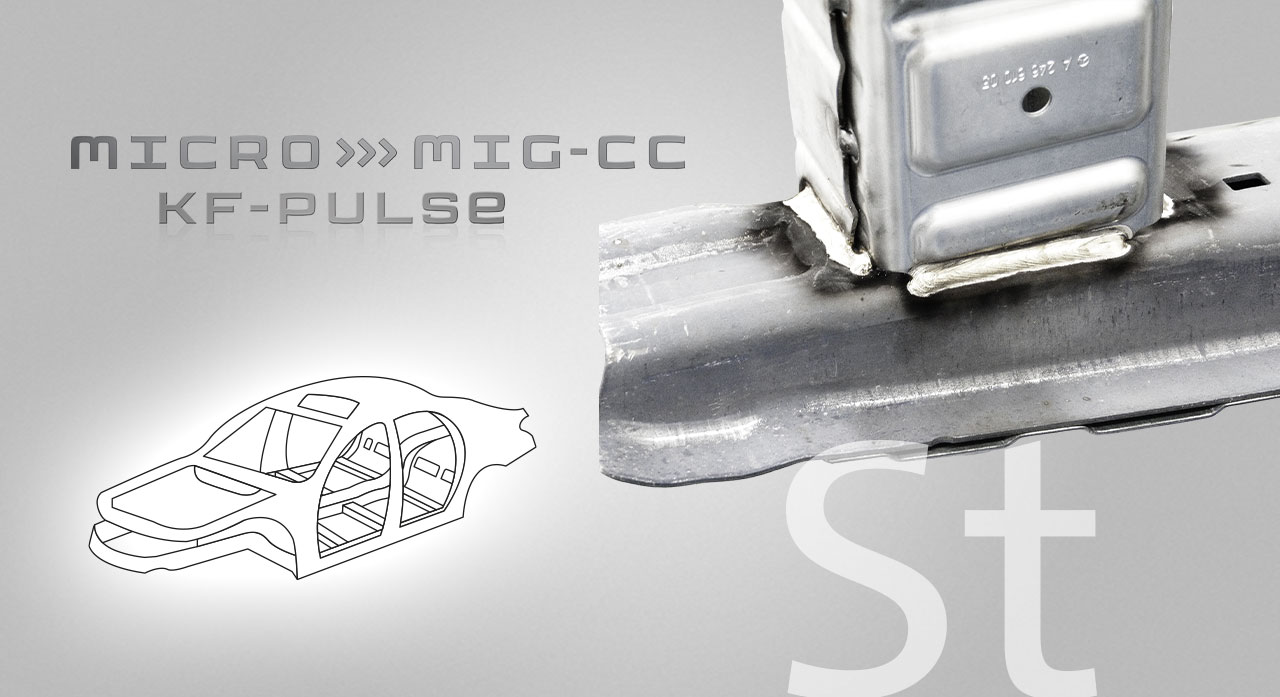

Application – Car Bodies:

Steel

SKS copes with all the challenges posed by modern vehicle bodies consisting of countless individual sheets with different base material combinations and material thicknesses. The range extends from medium-strength, zinc-coated thin sheets and high-strength, boron-alloyed steels with aluminum-silicon coating to mixed designs of these steel materials in combination with aluminum.

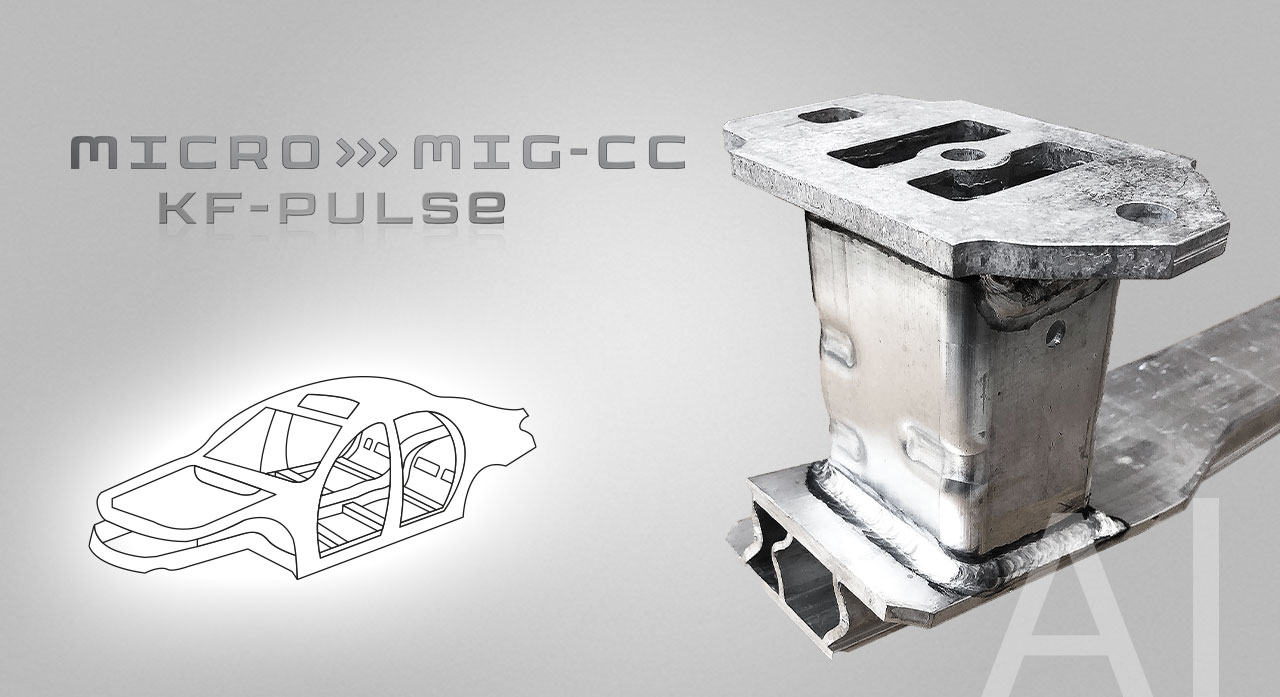

Application – Car Bodies:

Aluminum

Due to lightweight construction requirements, especially for sports cars or electric vehicles, complete vehicle bodies are also made of aluminum or produced as aluminum space frames with plastic outer skin.

Add-on parts such as doors, bonnet or boot lid are available in steel, aluminum and fiber composite versions.