Markus Klein

Managing Director

markus.klein@de.sks-welding.com

As an innovative systems partner of the automotive and supplying industries, SKS Welding Systems has been a pioneer of automated arc welding technology since the company’s foundation. Already in 1989, we developed and produced – in cooperation with our technology partner Leipold – the first weld process controller for robotic and automatic machine applications.

With forward-looking and customer-oriented developments and their integration into many different production environments, we support our customers in establishing continuous and efficient welding operations. In all this, there’s one combination that counts most: Highest possible availability of the welding systems at optimized cost efficiency.

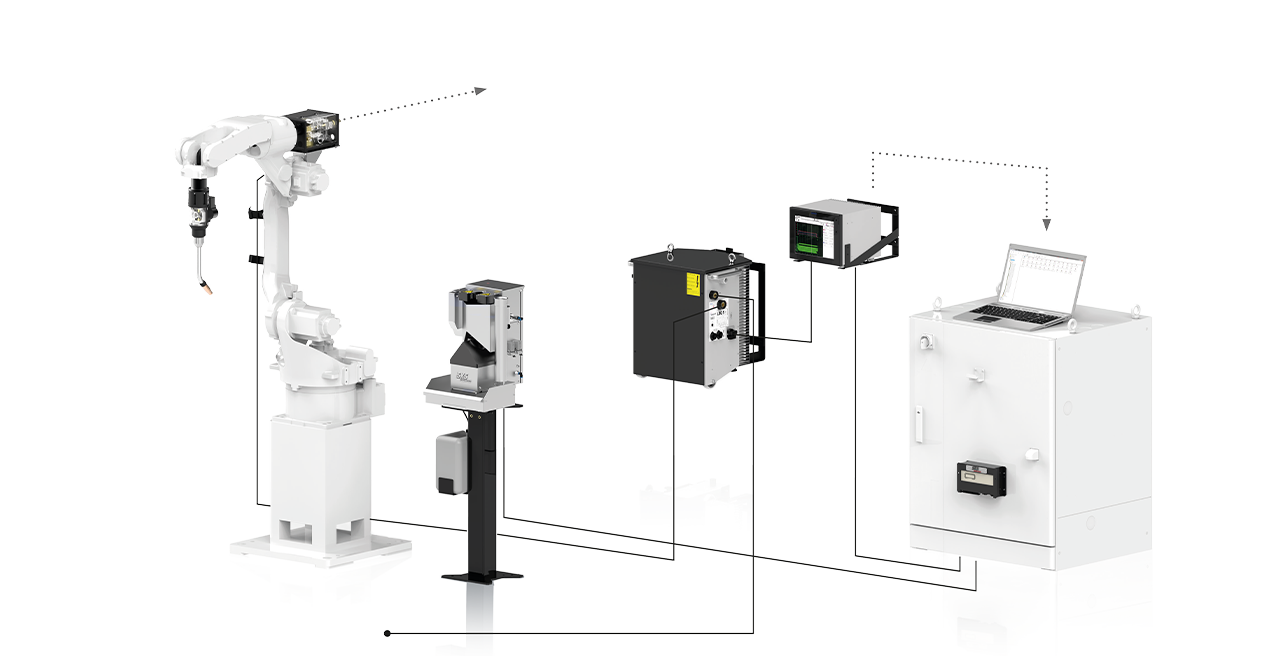

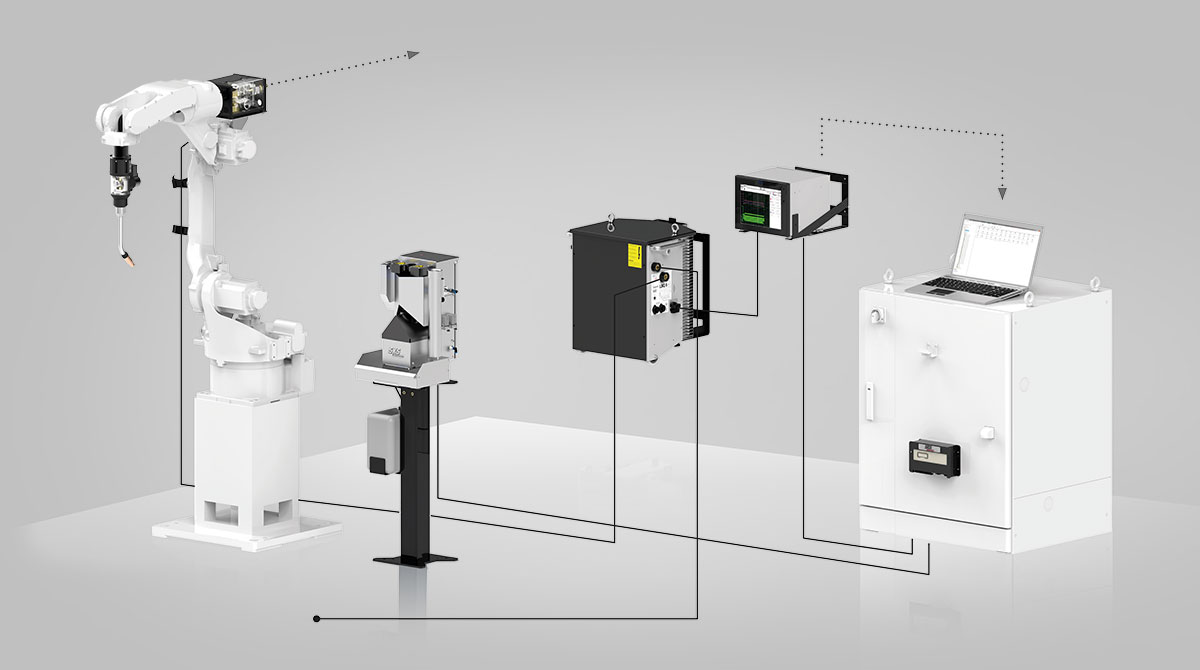

Our concept: The combination of a modularly designed welding machine made of high-performance components with a functional torch series for single wire and dual wire welding. Our systems are complemented by flexible software solutions for the documentation of welding data – from a stand-alone operation to network-integrated solutions. The welding machines and torch systems are compatible with all common welding robots.

What makes our products unique is their high reliability and long service life – because if there is one thing we don’t want, it’s a thriving repair and spare parts business.

Made in Germany – Made by SKS.

Managing Director

markus.klein@de.sks-welding.com

Managing Director

thomas.klein@de.sks-welding.com

Founder SKS

dieter.klein@de.sks-welding.com

Our development efforts follow a strict “plug & play” strategy: all components of a welding machine (power source, weld process controller, wire feeder, and robot interface) are interconnected via a single cable type – the L-700.

Strictly modular: function upgrades can be easily integrated via plug & play. Work-intensive and therefore costly readjustments or modifications are not required.

In close cooperation with our customers, we support and supervise projects from the welding of first prototypes to customer-specific training and up to the start of the production. With the finding of new material characterization curves, determining welding parameters and documenting welding trials we support our customers particularly during the project implementation phase.

Because we know: Only the perfect design of even the smallest details will lead to the desired quality and reliability of the whole system.

That’s what we do.

With its fine feeling for the potential of new technologies and future-oriented solutions, SKS understands itself as a creative and innovative partner of the automotive and supplier industries. A typical example for this is the fact that all welding systems can be easily connected to the controllers of all common industrial robots via the SKS Interfacing solution. Furthermore, the demand for a longer service life has become more and more important over the last few years – especially in the automotive industry.

The requirements: Optimized processes with less system installation and maintenance efforts and minimum investment.

Developments such as Direct Control Technology, the Power Joint torch system with limitless rotation, the Synchroweld control feature or the microMIG welding process contributes to the production benefits and market success of our customers.

The open and modular system architecture of our welding machines supports the integration of new technologies during the whole production lifecycle. This continuously creates further application options.

Real advantages for expandability.