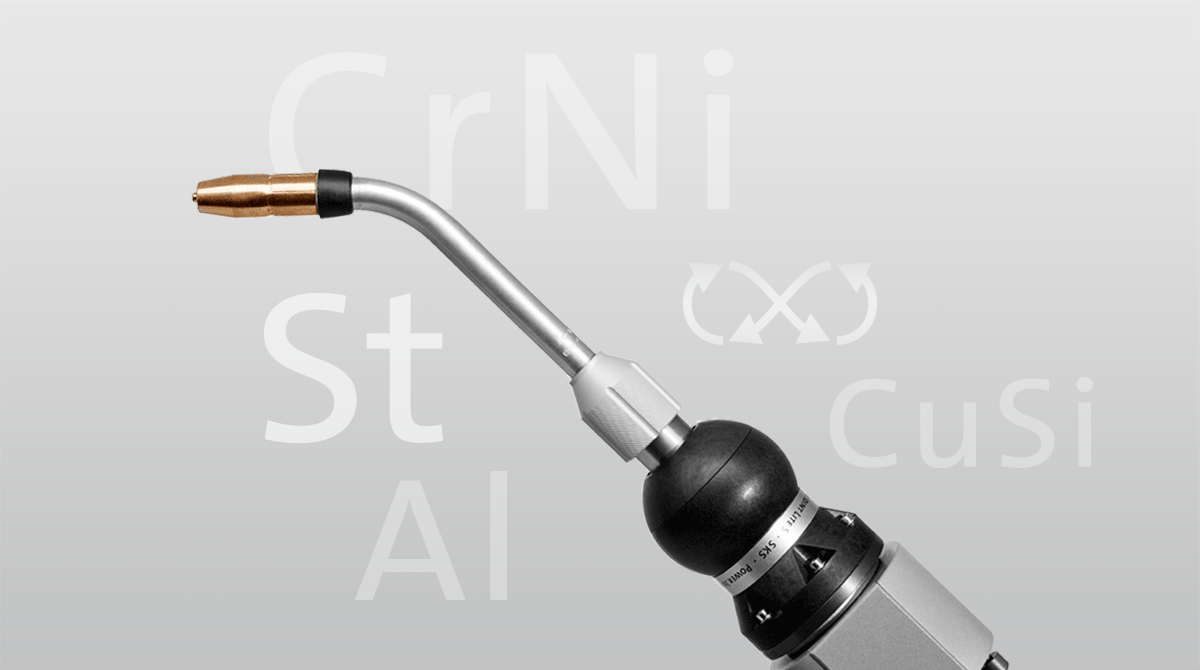

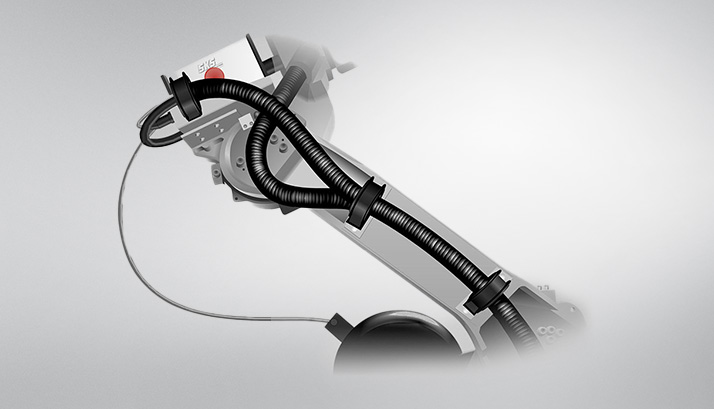

Power Joint Lite S:

For the perfect interaction between robot and welding system

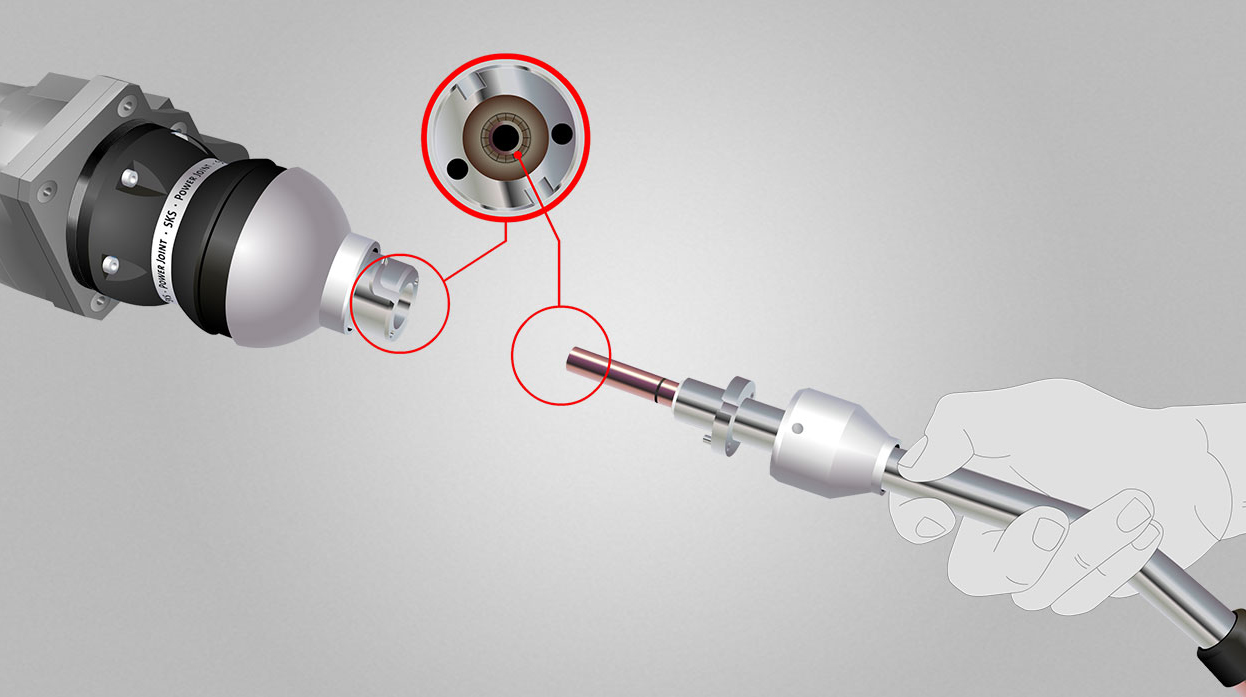

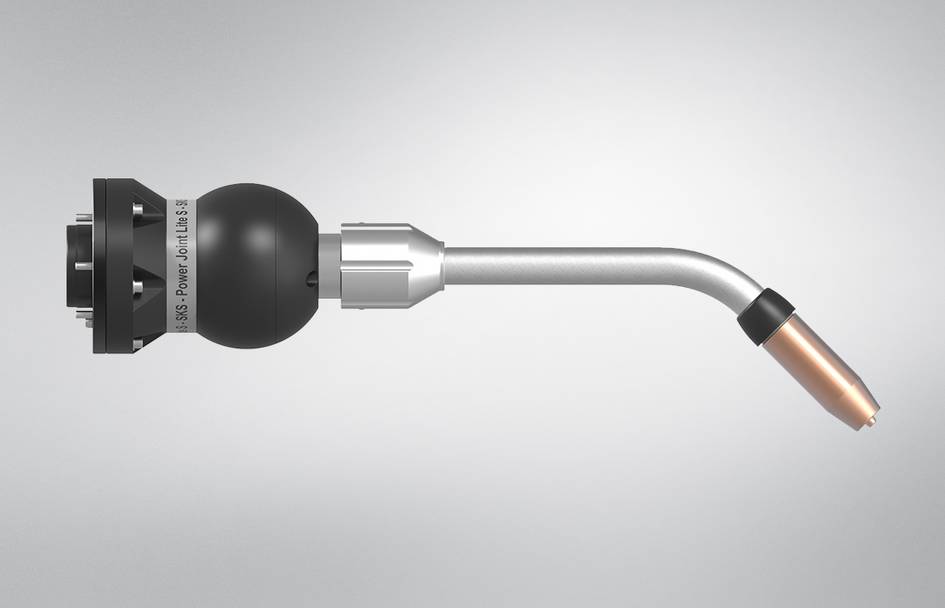

The Power Joint Lite S also has a rotary coupling between the torch and torch cable that allowsthe 6th robot axis to rotate without limit (beyond 360°, no stop) and also supports the transmission power, gas, air and wire. By decoupling the torch cable from the torch, all torsional stresses on the cable are avoided, resulting in a significant increase in the cable’s service life – and in the uptime of the entire production plant.

Thanks to its low weight and innovative design, the Power Joint Lite S torch system allows the robot to make full use of its maneuverability, especially in narrow robotic welding cells. Time-consuming reversing of the hand axis or limitations of the articulation axis are a thing of the past, the robot can reach any point by the shortest possible path. This also leads to considerably less effort during the teaching of the robot.

Perfect complement to the robot

The extremely stable and rigid structure of the Power Joint Lite S effectively supports the internal collision detection of the robot system and perfects the interaction between welding equipment and robot. Collisions with the component or fixture can thus be detected very quickly in all directions (X, Y and Z axes).

The elimination of additional cables and the mechanics of a switch-off box significantly increases the efficiency and reliability of the overall system.