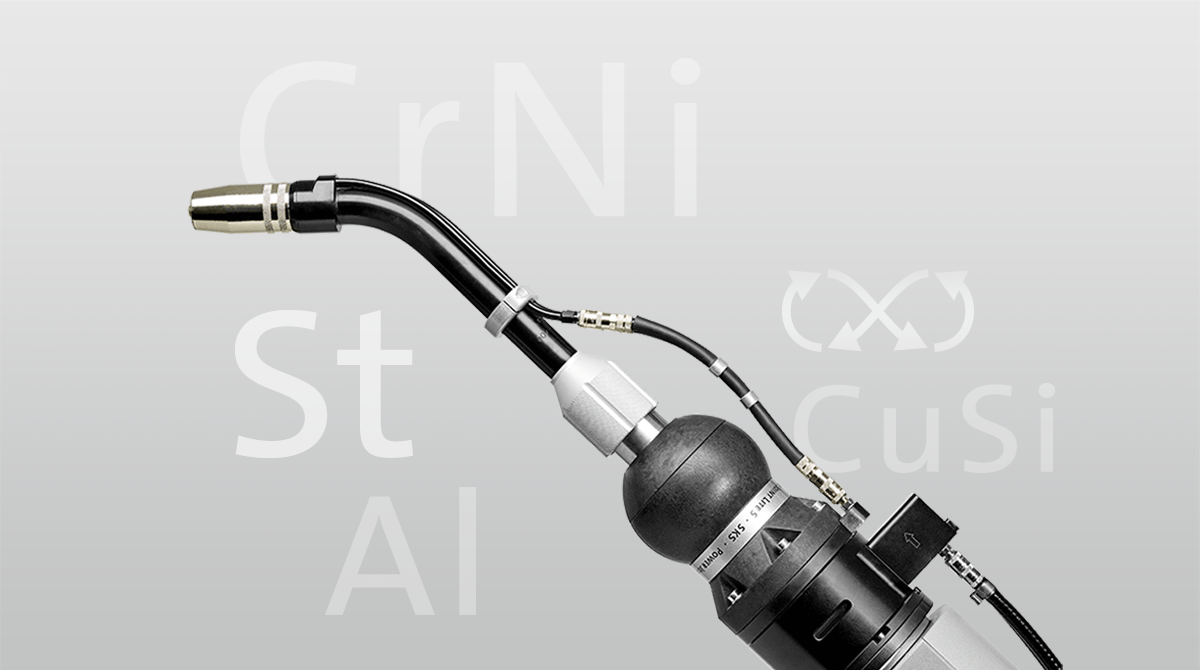

Water Joint Lite S:

Efficiency under extreme loads

The Water Joint Lite S torch system perfects the interaction the interaction between welding systems and robots with internal torch cable and enables use in higher power ranges.

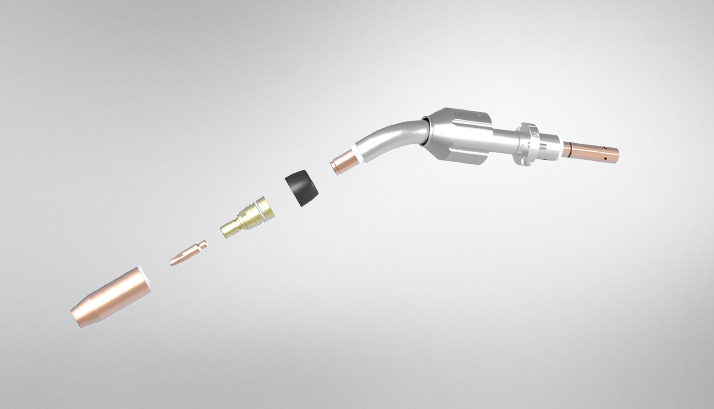

For some welding tasks, additional cooling is required to increase the service life of the wear parts. For applications with higher-than-average duty cycles and/or very high amounts of reflected heat, SKS developed the ‘Water Joint’ and ‘Water Joint Lite S’ torch systems. While other torch equipment uses water cooling to reduce cable cross-sections, SKS takes a different approach and supplements the heavy-duty, air-cooled torch systems with additional water cooling.

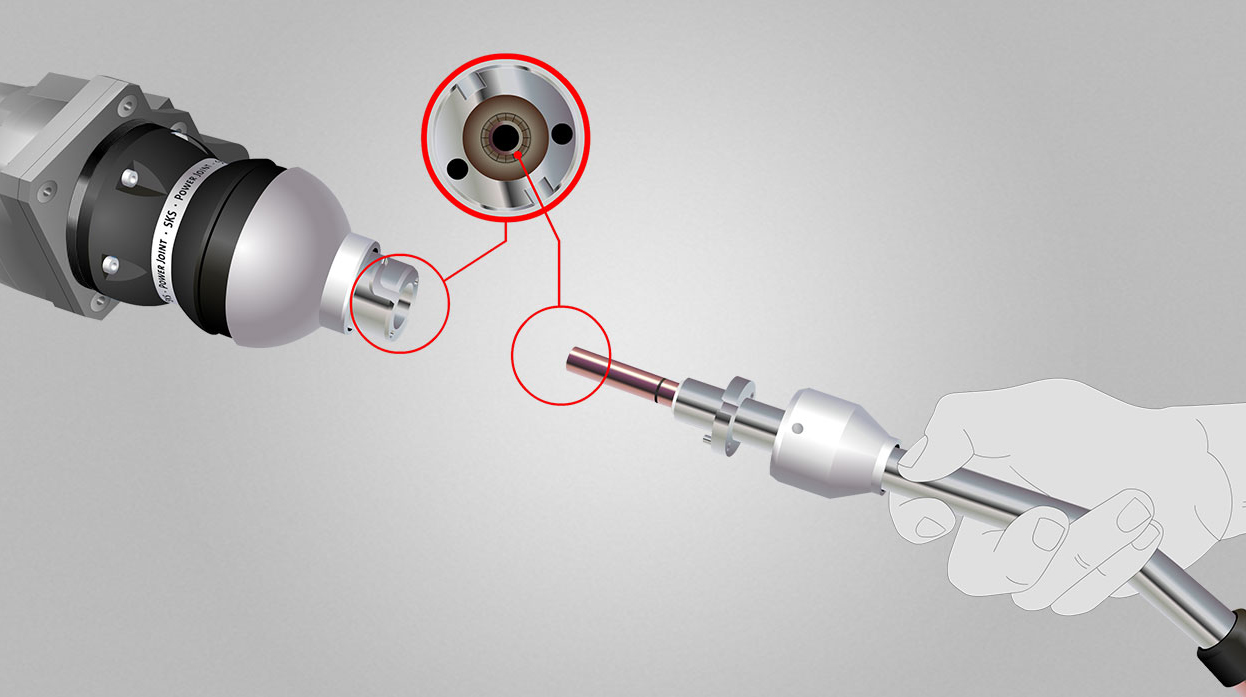

In the case of the Water Joint Lite S, the rotary coupling of the Power Joint Lite S, which has proven itself many times in industrial series production, is supplemented by a water coupling that can also be rotated endlessly – meaning that the Water Joint Lite S has the same technological advantages offered by the decoupled torch cable. In addition to welding current, shielding gas, air and wire, the rotary joint of the Water Joint Lite S also transmits the cooling water.

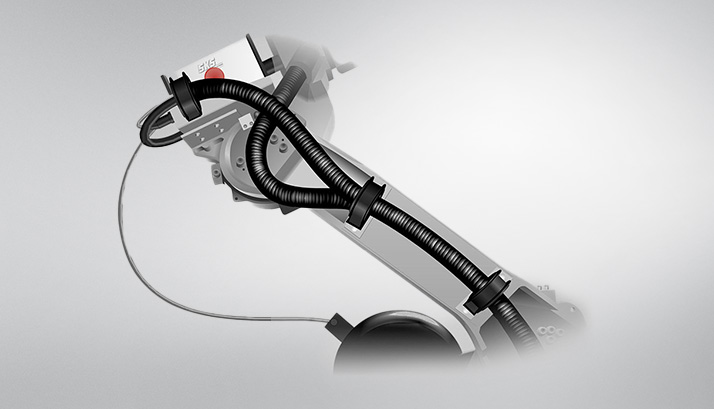

The innovative water-cooled torch system helps the robot to make full use of its movement potential. Time-consuming reversing of the hand axis or limitations of the articulation axis are a thing of the past – the robot can reach any desired point by the shortest possible path.

Perfect complement to the robot

The extremely stable and rigid structure of the Water Joint Lite S effectively supports the internal collision detection of the robot and perfects its interaction with the welding system. Collisions with the component or fixture can thus be detected quickly in all directions (X, Y and Z axes). Another advantage: Avoiding additional cables and also the mechanics of a cutoff box significantly reduces the cost of the overall system.