Frontpull 8i Lite:

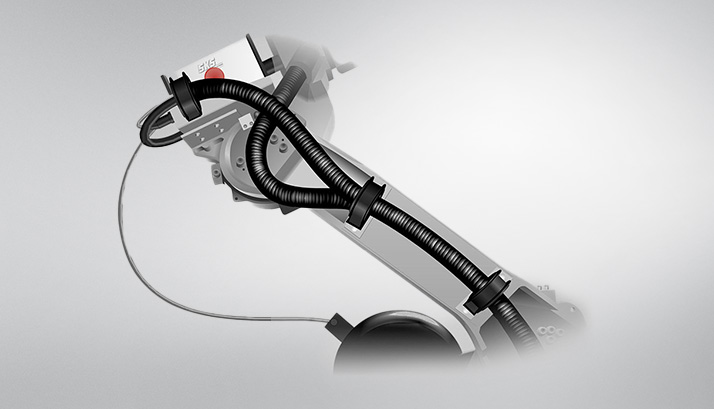

Optimal support of robots’ internal collision detection. A rigid torch system enables the precise setting of the robot parameters.

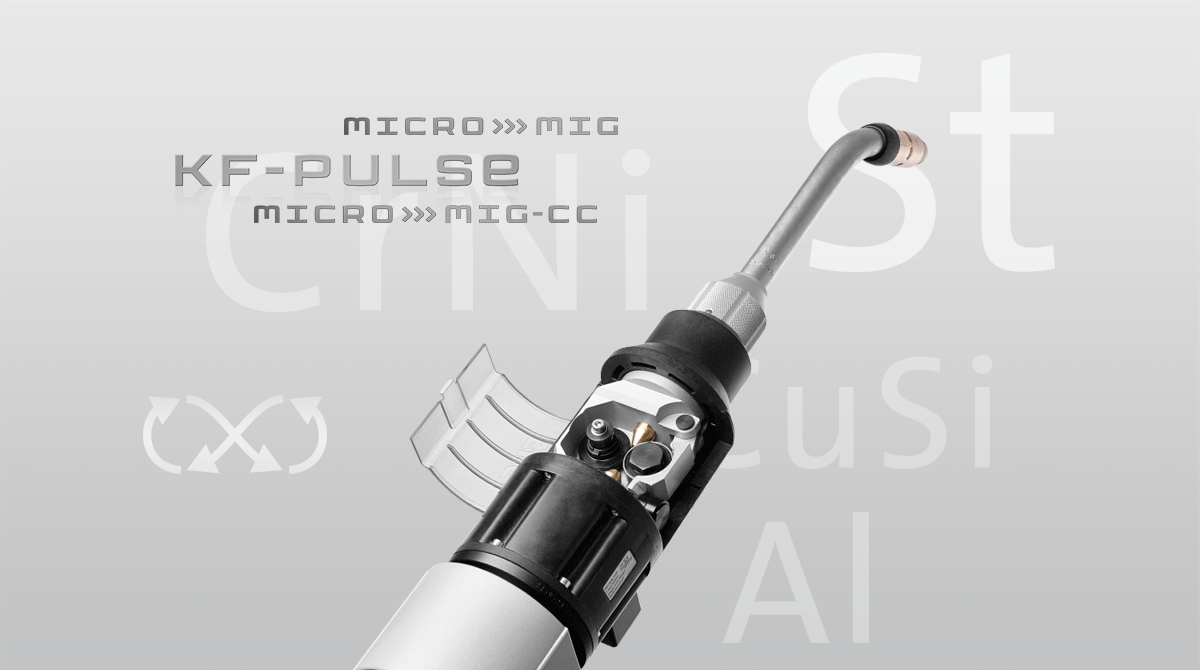

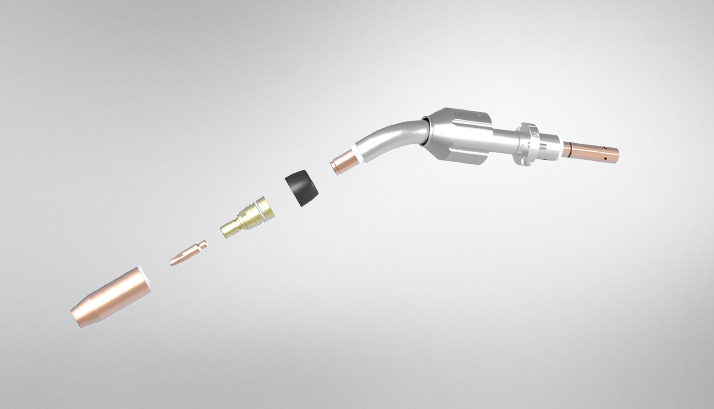

The Frontpull 8i Lite torch system (just as the Frontpull 8i) combines all the advantages of the endless rotating coupling (beyond 360°) and the integrated wire feed into a very compact and lightweight unit for robots with internal torch cable. The compact design allows an optimal torch position at any time – even in narrow robotic welding cells and fixtures.

The stable and rigid structure of the Frontpull 8i Lite effectively supports the internal collision detection of the robot system and perfects the interaction between welding equipment and robot. Collisions with the component or fixture can thus be detected very quickly in all directions (X, Y and Z axes).

The elimination of additional cables and the mechanics of the switch-off box significantly increases the efficiency and reliability of the overall system. The integrated and highly precise wire feed enables the use of the heat-reduced microMIG and microMIG-CC welding processes. In combination with the Frontpull module mounted on the robot, the safe conveying of soft aluminum filler materials is effectively supported.

Long durability, high availability and safe wire feeding support the user in many applications areas while ensuring high efficiency.