Additive Manufacturing

In additive manufacturing, three-dimensional workpieces are produced by building up layers, similar to a 3D printing process, or existing components are supplemented or modified by adding further layers. Production is usually made using the CAD data of the respective components, without special molds or tools. The high flexibility allows the fast and individual production of prototypes and small quantities. Several processes are available in metal processing, among which the so-called Wire Arc Additive Manufacturing (WAAM) stands out as a very flexible and inexpensive option.

SKS Welding Systems has been involved with WAAM production technology for a longer time and already provides automated production machines with the necessary welding equipment. The simple and cost-effective Wire Arc Additive Manufacturing process uses filler wires that are melted with an electric arc to form weld beads that are stacked in layers to create the desired geometric shape. The path of the welding torch is usually guided by a robot or a 3D guidance system in an automatic production machine, into which the 3D data of the component can be directly fed. The often very complex blanks are then finished by means of machining processes.

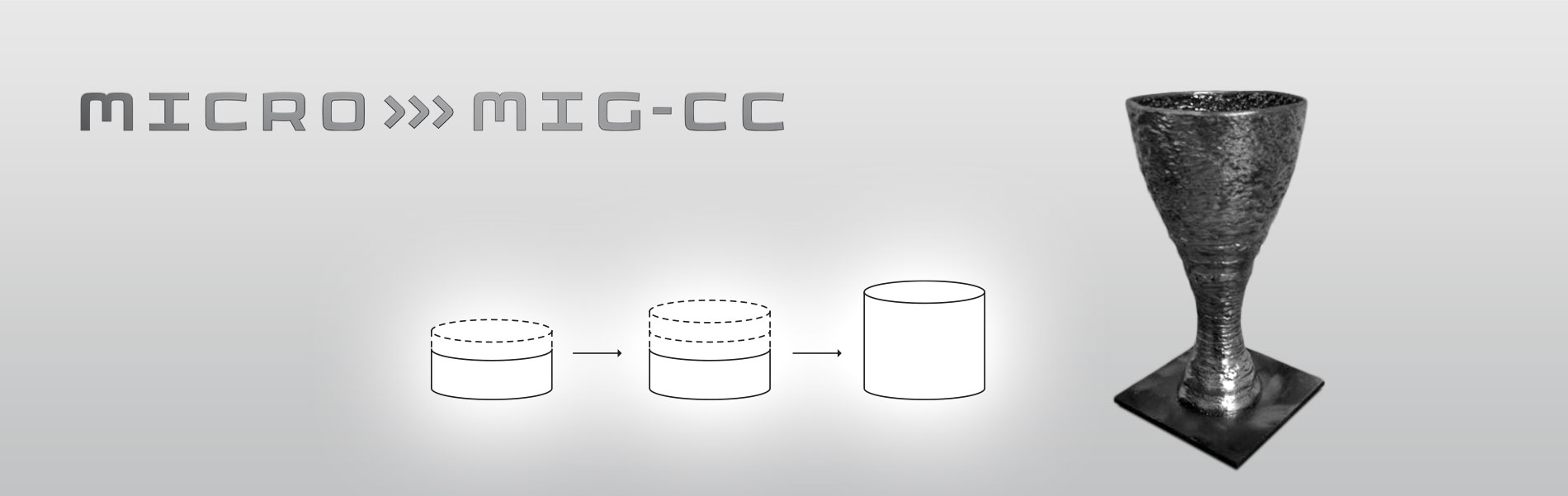

Sample workpiece:

Cup

steel, high-alloy steel, aluminum | |

|---|---|

| Workpiece height: | 190 mm |

| Wall thickness: | 4 mm |

| Diameter: | min. 28 mm; max. 110 mm |

| Welding process: | microMIG-cc |

| Base material 1: | base plate S355 |

| Filler material: | G3Si1 (ER 70-S) 1,0 mm |

| Shielding gas: | 92 % Ar - 8 % CO2 |

By using the microMIG-cc process and manufacturing parameters optimized for Wire Arc Additive Manufacturing, maximum layer build-up can be achieved. The fed-in energy is primarily used for melting the filler material. The aim is to achieve the highest possible weld build-up in order to achieve the required component height quickly and with as few layers as possible.

Welding with Additive Manufacturing : Presentation Advanced Metal Deposition (AMD) process

SKS welding application for additive manufacturing: Sample workpiece

Video: SKS welding application for additive manufacturing: Sample workpiece