Additional Functions

Today, machine-machine and human-machine communication is becoming increasingly important. The transmission of existing information can sustainably improve processes and significantly increase efficiency. Automated information processes reduce manual effort and lead to significant increases in efficiency.

By monitoring and tracing process parameters, production quality is ensured and deviations from standard values are detected at an early stage. Undesired effects on the production process can be counteracted before they mutate into problems.

The SKS welding system includes a number of freely usable special functions that significantly improve or extend the communication between the robot and the welding system, but also with the user. These offer the often decisive added value over other welding systems when it comes to optimizing production processes and achieving maximum performance from the welding equipment.

Application:

Additional Functions

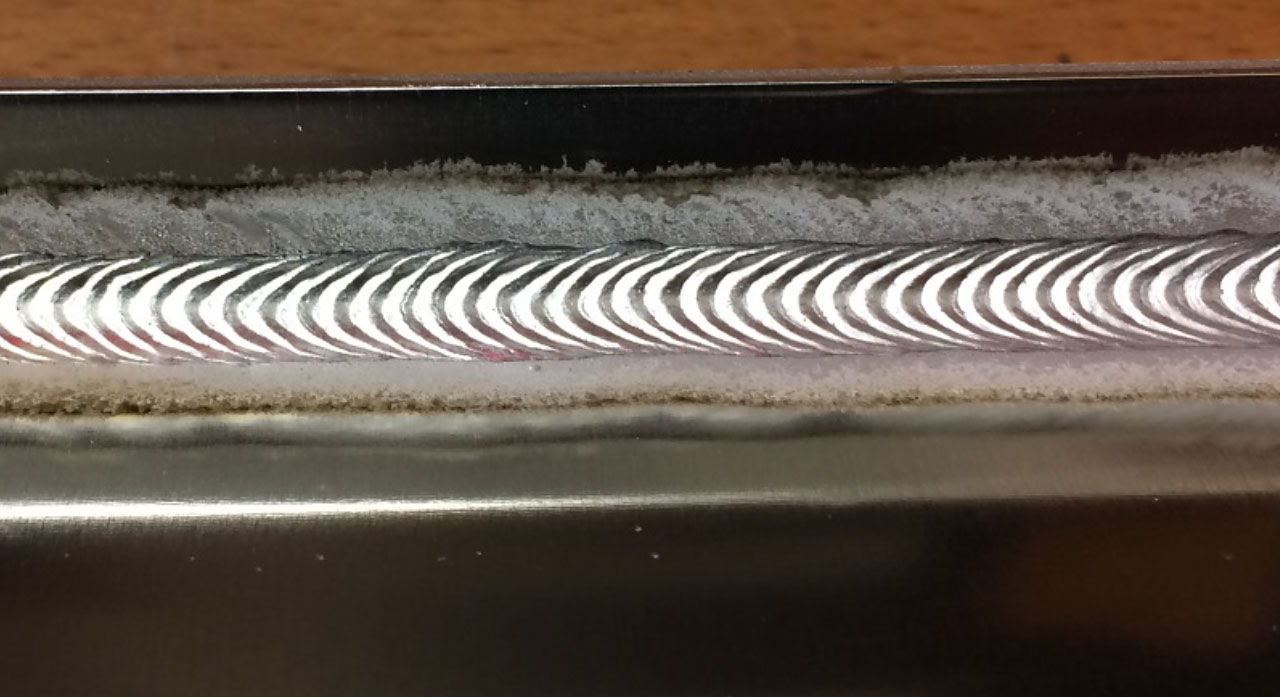

The special functions integrated in every SKS welding system are designed to support the user in achieving the best possible weld quality and maximum availability of the welding equipment. Supporting functions such as Synchroweld or AutoComp help the user in their daily tasks and ensure that the process is as trouble-free as possible during the production phase.

Monitoring functions report deviations from normal working parameters and support root cause analysis with detailed error messages. In this way, creeping problems can be detected at an early stage and necessary maintenance work can be scheduled. Documentation functions relieve staff through fully automatable report generation and traceability options.