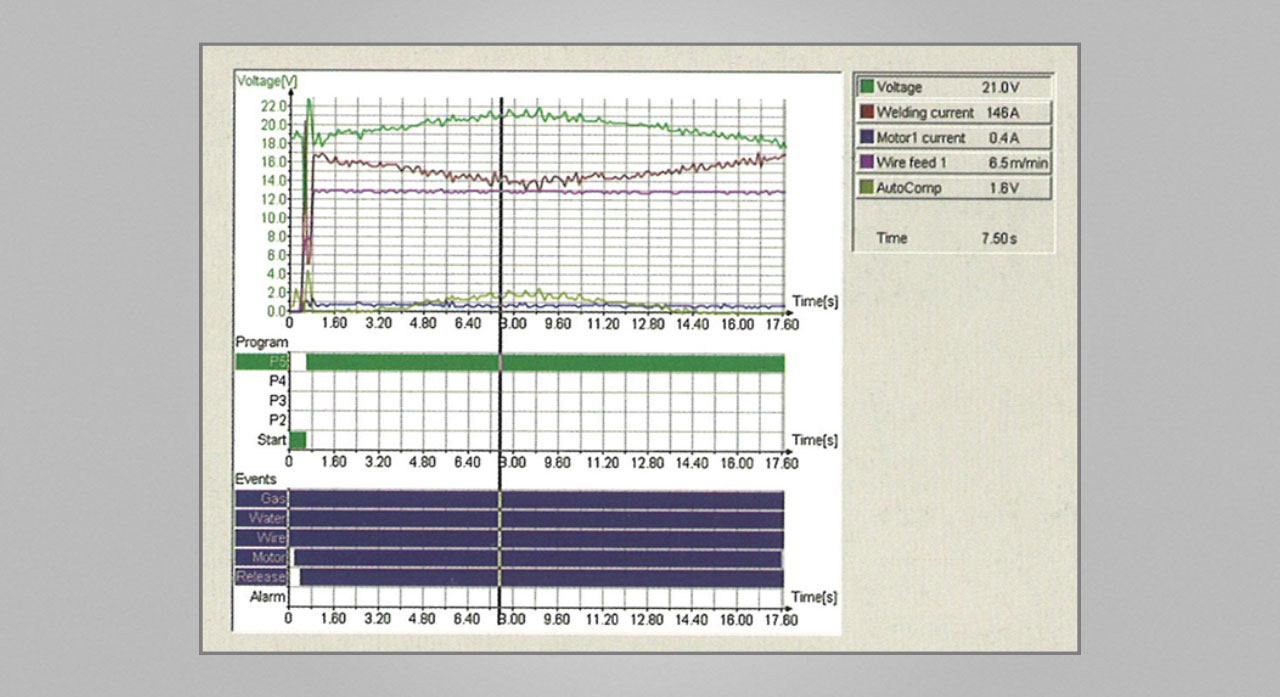

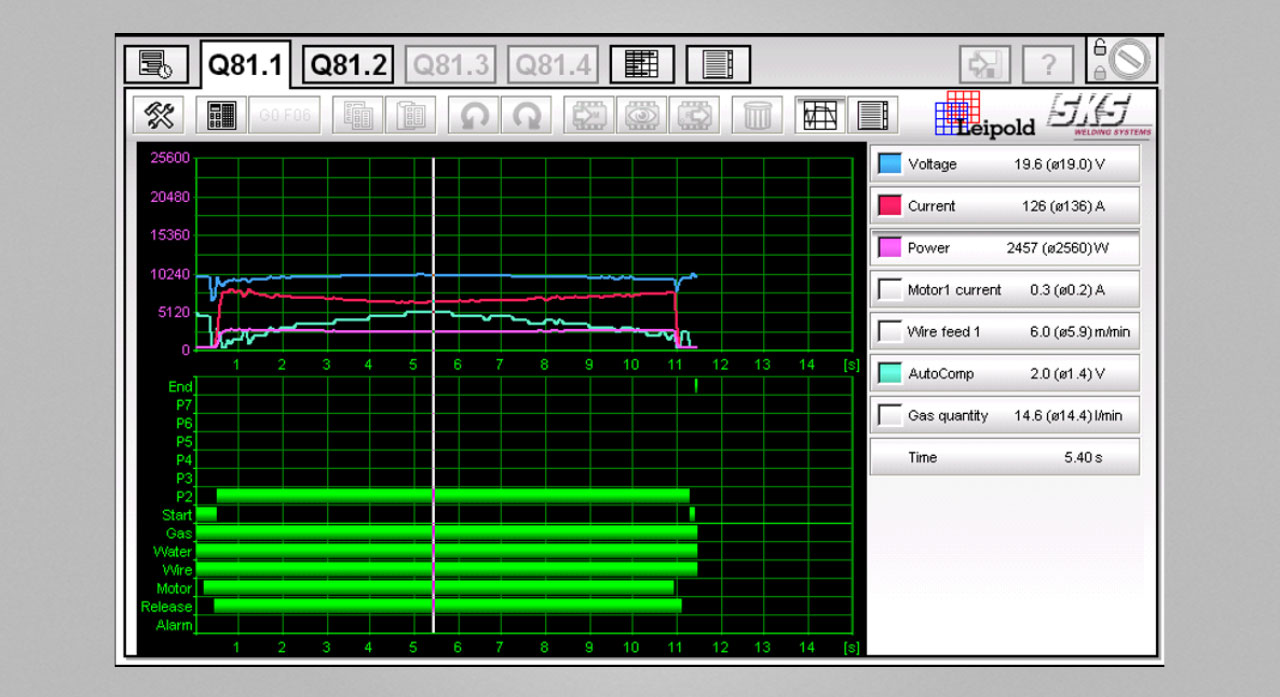

AutoComp (auto compensation):

Fully automatic resistance compensation

The AutoComp function compensates for resistance changes in the welding circuit caused by defective cables, inadequate ground transfer or differing torch distances fully automatically during welding. Changes in resistance are compensated for by targeted readjustment, thus keeping the energy input and the welding result constant. Readjustment can be additionally monitored and limited. Exceeding the permissible values can be used to interrupt the welding process or for preventive maintenance of the robot welding system.

Special features – AutoComp

- constant energy input

- consistent weld penetration

- stable and consistent weld seam quality

- measured value recordings support optimization and troubleshooting

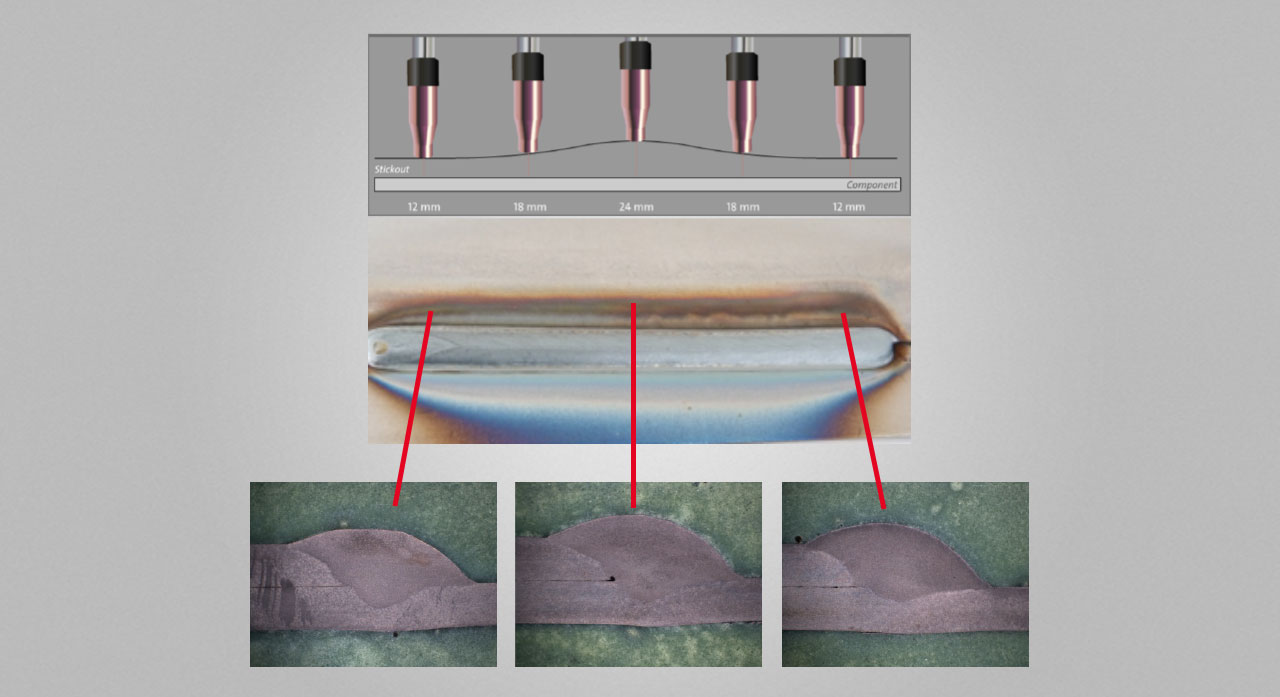

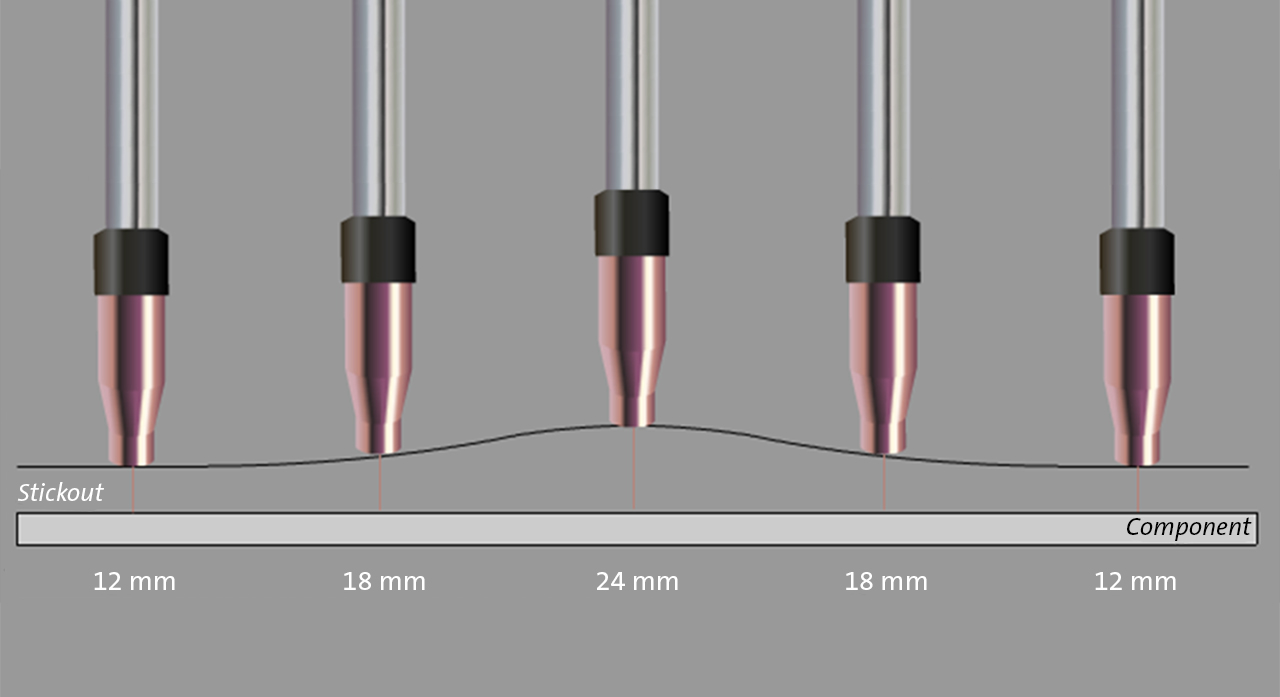

Simulation

Increasing the torch distance increases the resistance in the welding circuit. With AutoComp, the rising resistance is detected and dynamically readjusted. Energy input, penetration and welding result remain consistent. Deviations from the standard value are documented in the measured values and help the user in optimization and troubleshooting. Without AutoComp, this would go undetected and lead to a reduction of the heat input and to a narrow, excessively high weld seam without the required penetration. The investigation of the causes would be more complex and time-consuming.

Video: SKS AutoComp (automatic resistance compensation while welding)

This might also interest you