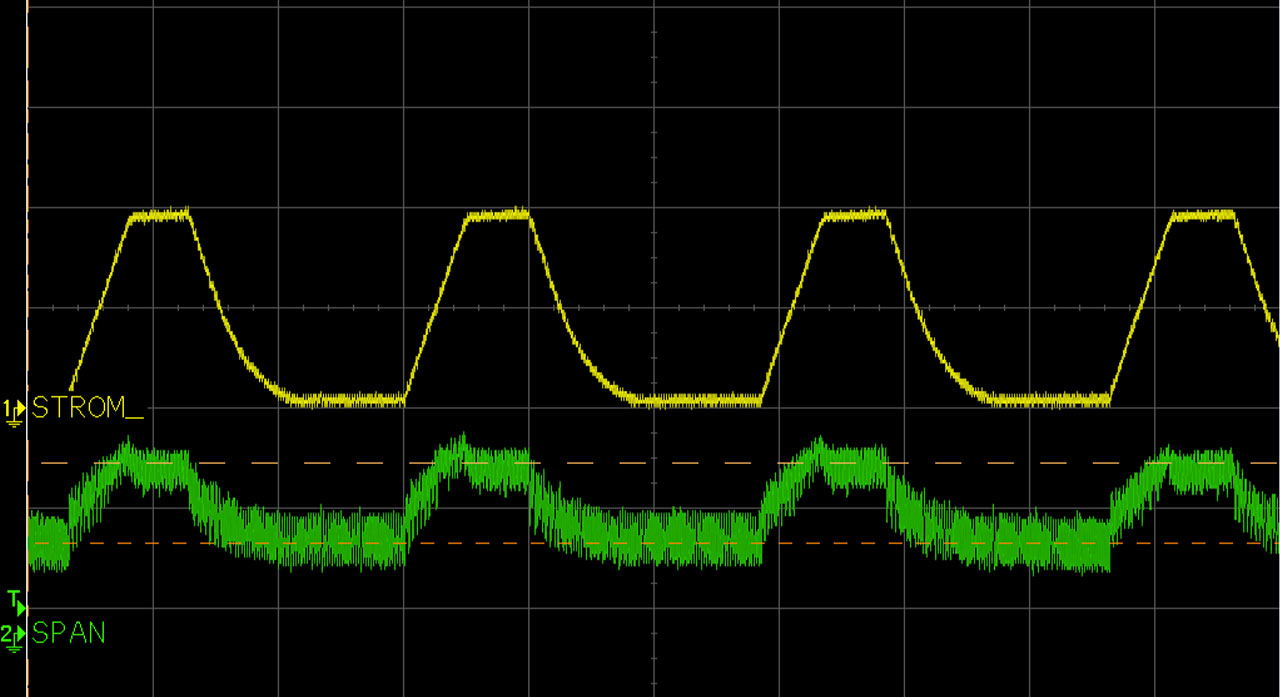

I-pulse Process:

The standard pulse procedure

The current-controlled pulse is the standard pulse method and is available in all modern pulse current sources. A controlled periodic change between two different current levels leads to a short-circuit-free and controlled material transition. Each pulse heats the base material and creates a single droplet which is formed at the end of the wire, detached and transferred to the molten weld pool. During the base current time, the material cools down and the wire is brought closer to the weld pool. Depending on the filler material, all necessary pulse parameters are suggested by the synergetic characteristic of the weld process controller. Similar to the MIG/MAG process, arc length and frequency corrections can be made via the averaged welding voltage. The I-pulse process is simple to set up and easy for the user to understand.

Special features – I-pulse process

- easy handling

- automatic arc length control

- automatic resistance adjustment (AutoComp)

- short-circuit-free material transition

- good heat transfer

- reproducible penetration

- can be used with all SKS Weld Packages

Highspeed video: I-pulse welding process

This might also interest you