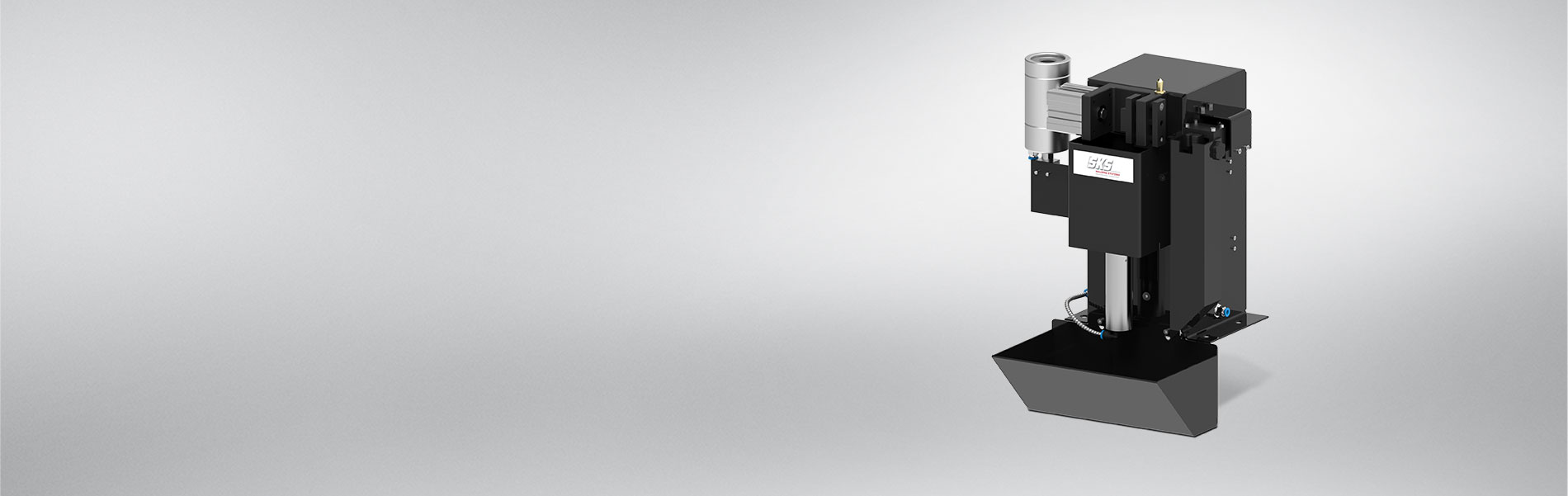

pReam: Pneumatic Cleaning Station

The pReam torch cleaning station by SKS ensures a good and easy cleaning process.

The easy-to-handle cleaning of the gas nozzles as well as its reliable function and simple system integration are among the basic features of the pReam. Simple integration without complex security hardware and effective cleaning were the basic requirements of the development. Compressed air, combined with proven reamer cleaning, is the recipe for success for the pReam cleaning system.

Learn more about our Reamer Blades

Downloads

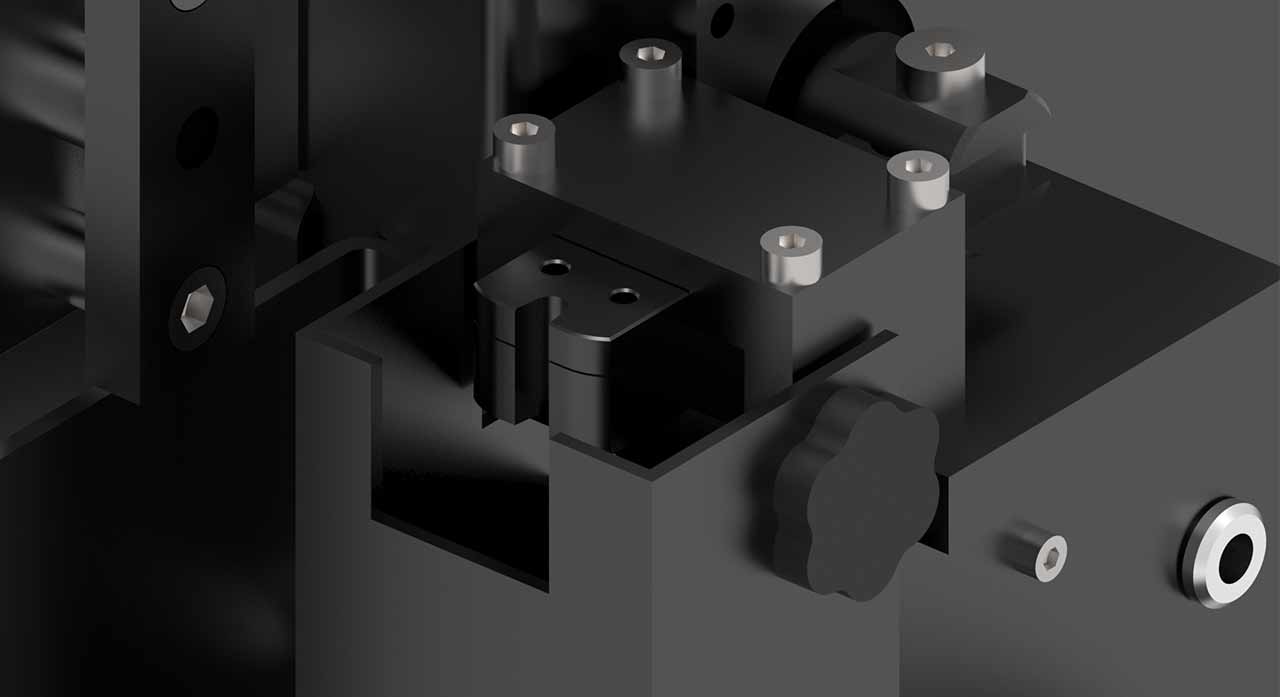

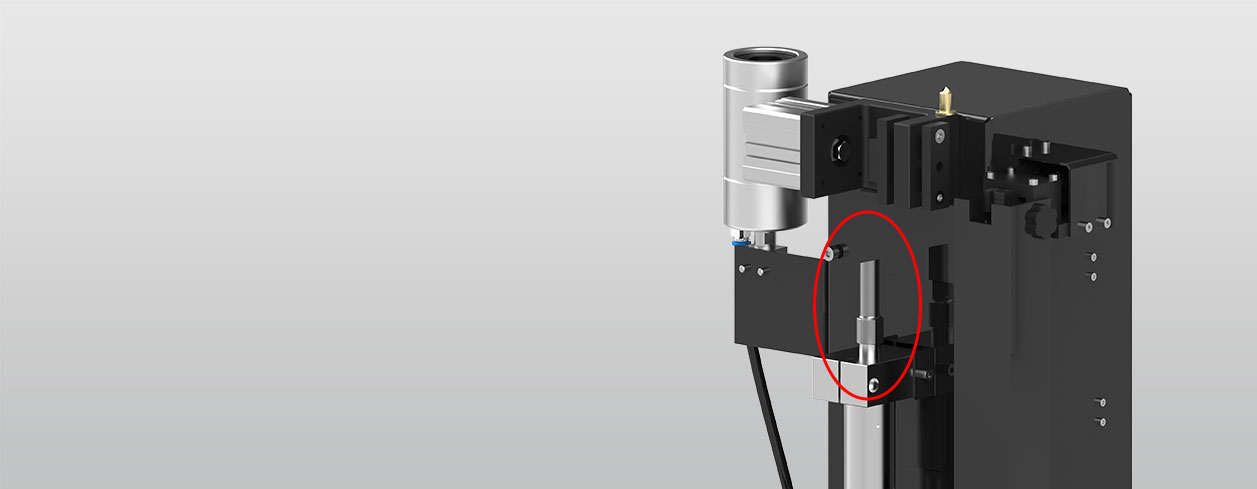

Cutting

- Can be used on all types of wire

- Max. size of solid wire is 1.6 mm

- Max. size of flux-core wire is 3.2 mm

- Replaceable cutter blades

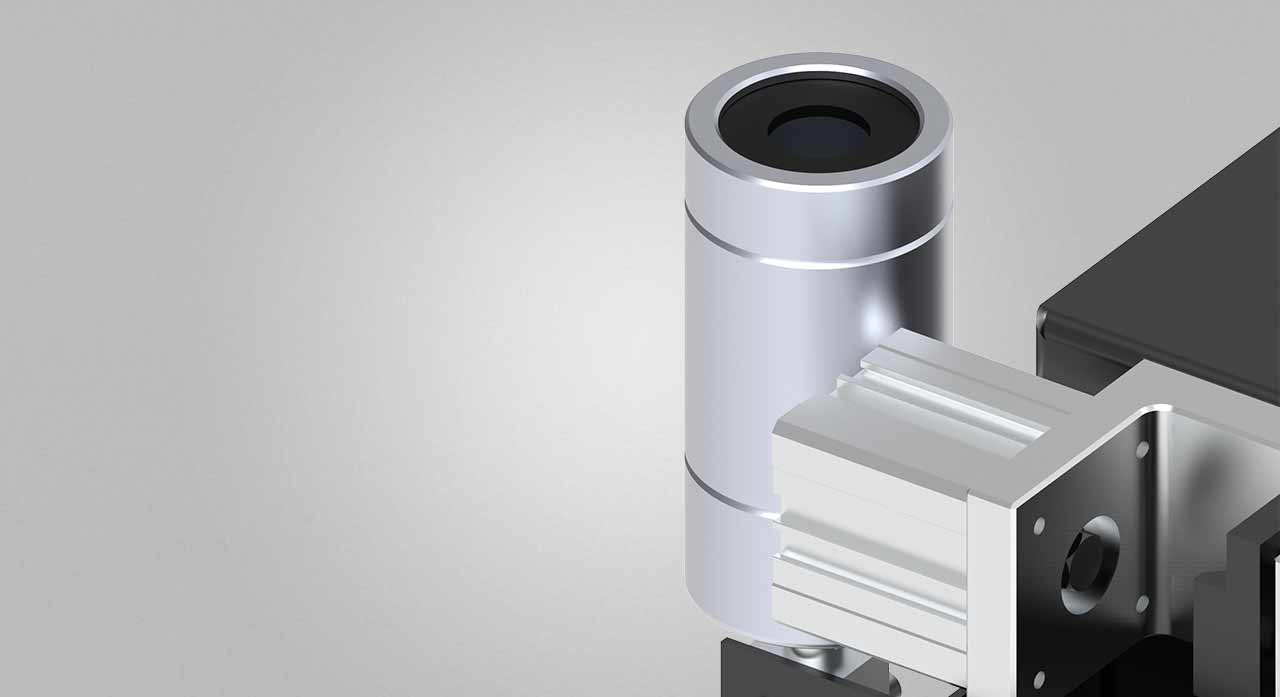

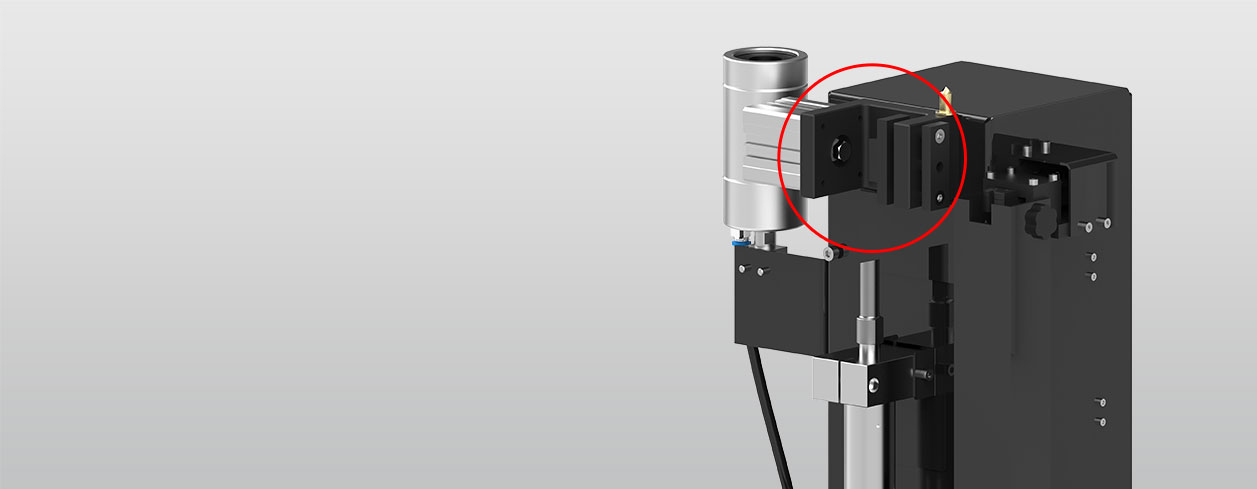

Nozzle Cleaning

- High precision and strong pneumatic motor with high torque

- Compatible with Clamp nozzles with max. 28 mm O.D.

- No need to change V-Block

Reaming

- Large selection of reamer blades

- Removes heavy spatter

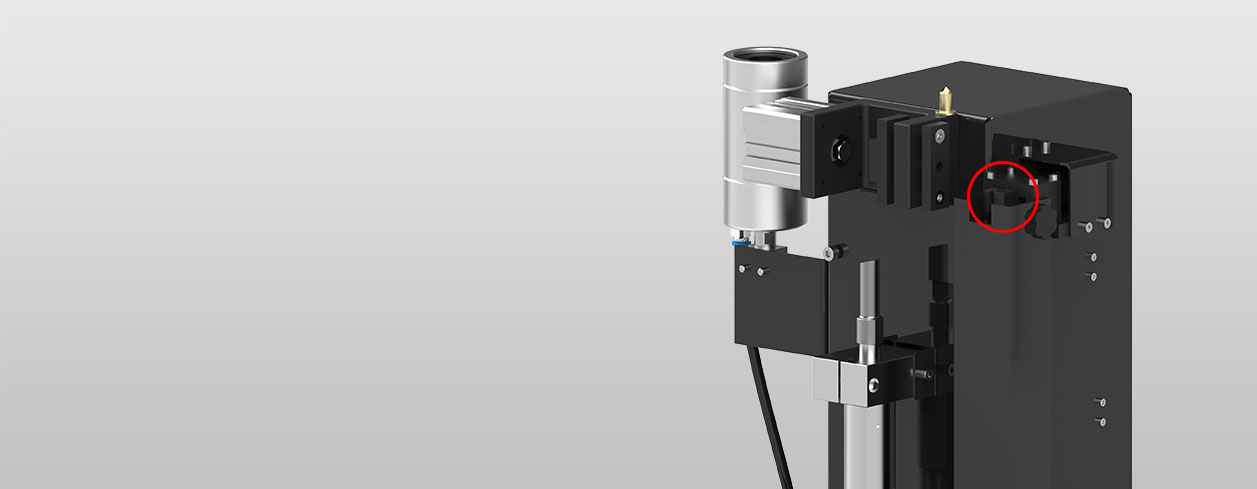

Spraying

- Closed spray chamber to prevent overspray in weld cell

- Overspray is collected and can be recycled

- Environmentally friendly

- Uses water based anti-spatter fluids

- Adjusting spray flow without opening the unit

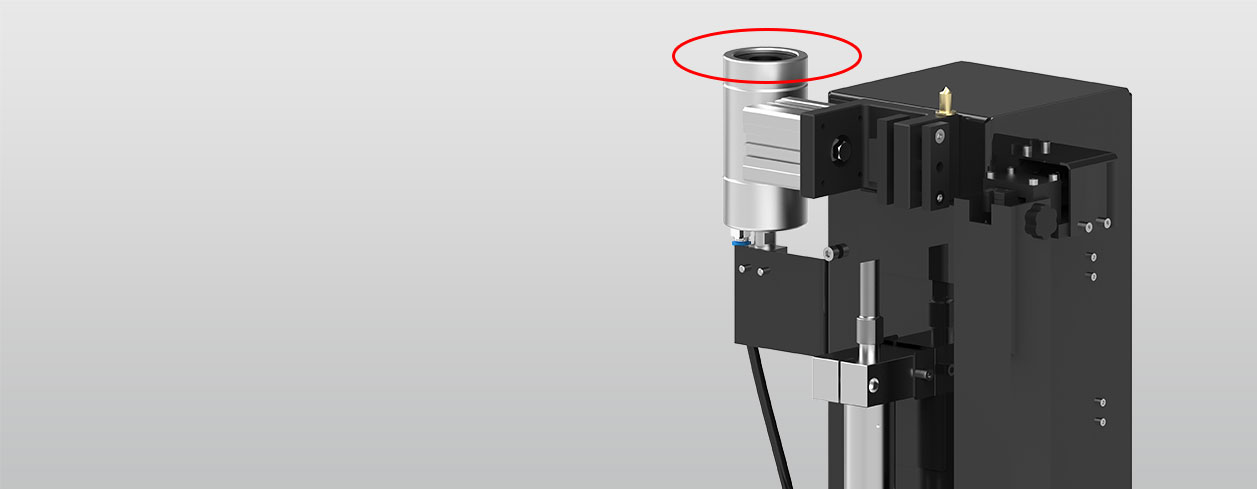

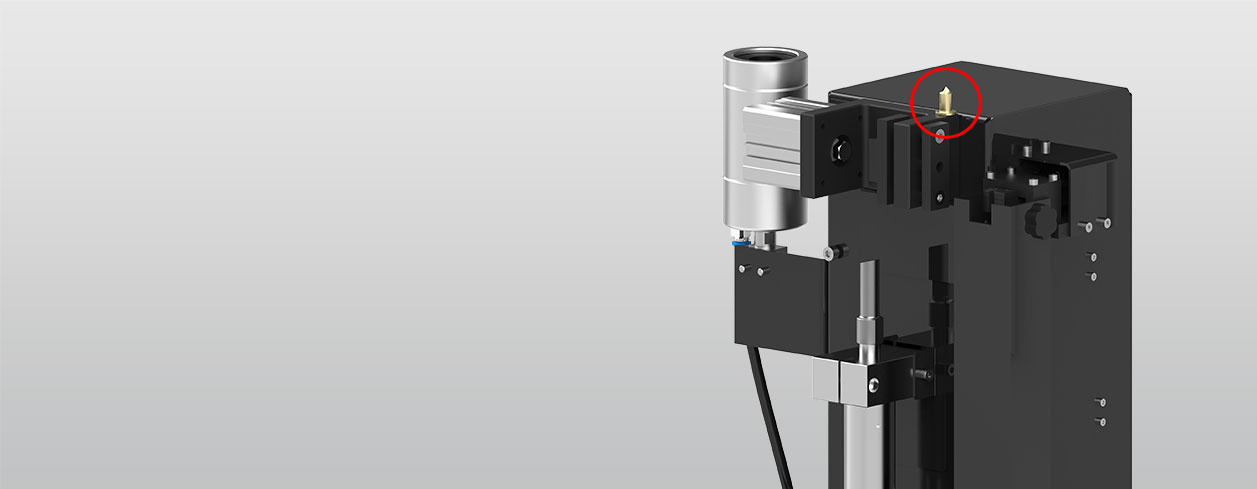

TCP

- Pointer for easy of TCP verification

- Conveniently mounted for improved visual confirmation of TCP

Technical specifications

- Air Input: Dry-Oiled Compressed Air, 6-8 bar (87-116 psi)

- Operating Temperature: -5 °C - +50 °C

- Air Consumption: ~6.3 L/s

- Pneumatic Motor: ~650 rpm | max. torque 9 Nm

- Control Voltage: 24 V DC

- Control Current: Imax = 0.15 A

- Cleaning Fluid Capacity: 5 L

- Fluid Waste Bottle Capacity: 5 L

- Wire Cutting Ability: Solid Wire: max 1.6 mm | Flux-Cored Wire: max. 3.2 mm

- Cleaning time: ~4.0 s (variable control time)

- Cutting time: ~0.5 s

- Max. Nozzle Diameter: 28 mm (bigger clamping blocks available on request)

- Spatter Spray Chamber: Closed design

- TCP Inspection: Tip attached on device

- Dimensions in mm (LxWxH): 235 x 320 x 330 (Stand Heigth: 750 mm)

Benefits - SKS pReam

- Available with or without stand

- Sprayer and wire cutter included

- Spatter and cut wire collection tray

- Manages both sinking and sourcing controller logic

- Adjustable pneumatic motor position to fine tune clean capability

- Simple and flexible programming – no special or costly control systems required