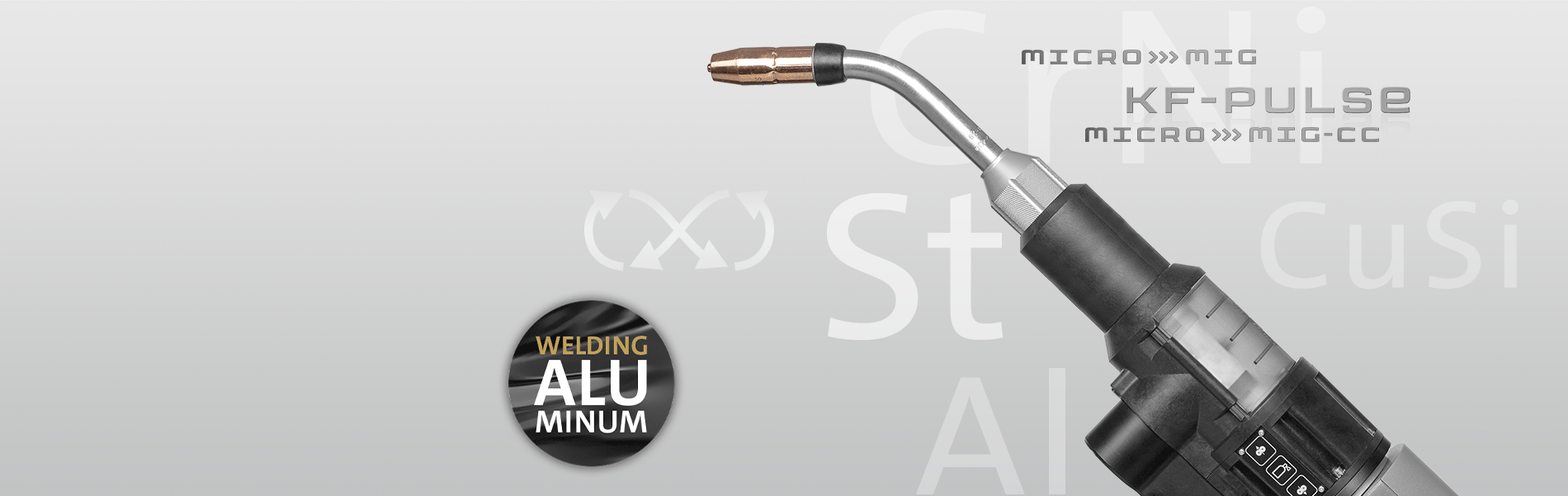

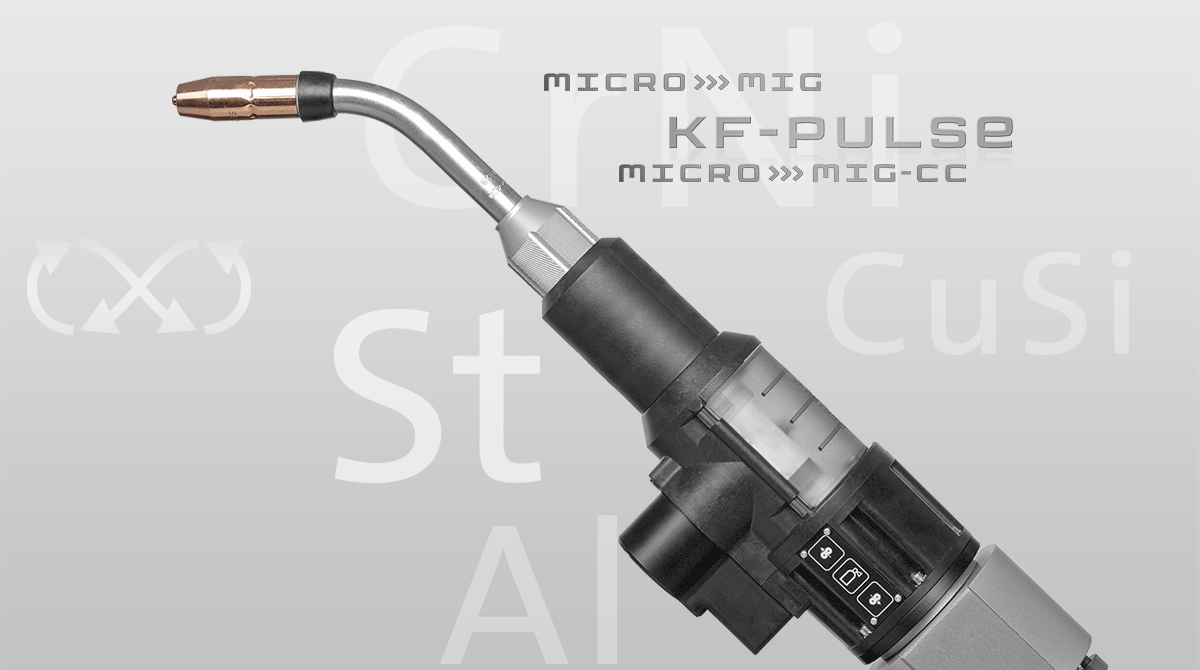

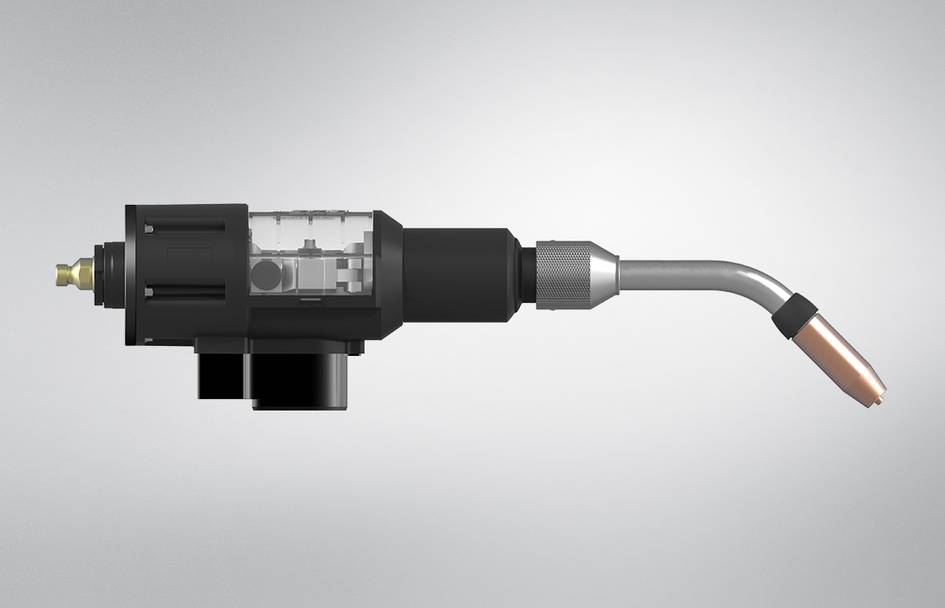

Frontpull 8i:

Endlessly rotatable welding torch from SKS with close-to-process wire feeding

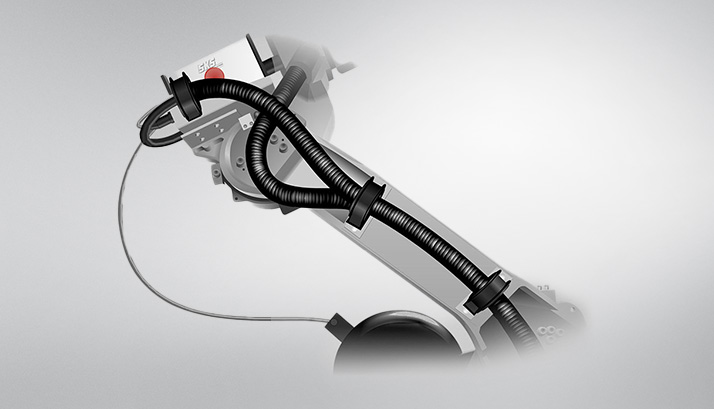

The Frontpull 8i torch system combines two design principles: From the proven Power Joint comes the principle of the high-current rotary joint. It dissolves the otherwise rigid connection between the robot and the welding torch. The result: The robot-guided torch can rotate endlessly – even beyond 360°. The wire feeding, the flow of electric current, electric signals and inert gas works without restriction – and without torsion of the torch cable.

The second design principle is wire feeding close to the process. This innovation is only possible thanks to the high-quality and lightweight engine. The highly dynamic 50 W brushless DC motor provides advantages otherwise only offered by a servo motor.

The high-precision wire feeder enables the use of the heat-reduced microMIG and micoMIG-cc welding processes and supports the uniform feeding of aluminum filler metals. By opening an electrical contact, the integrated collision detection system reports collisions with the workpiece or fixture, protecting both the robot and torch system from damage.

With its light weight and compact design, the Frontpull 8i also features the advantages of robotic systems with small payloads.