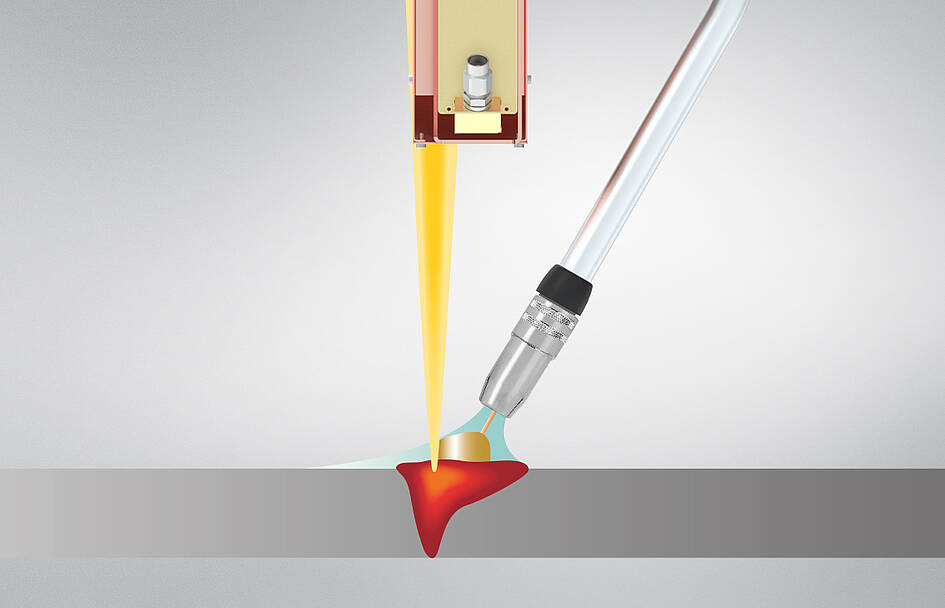

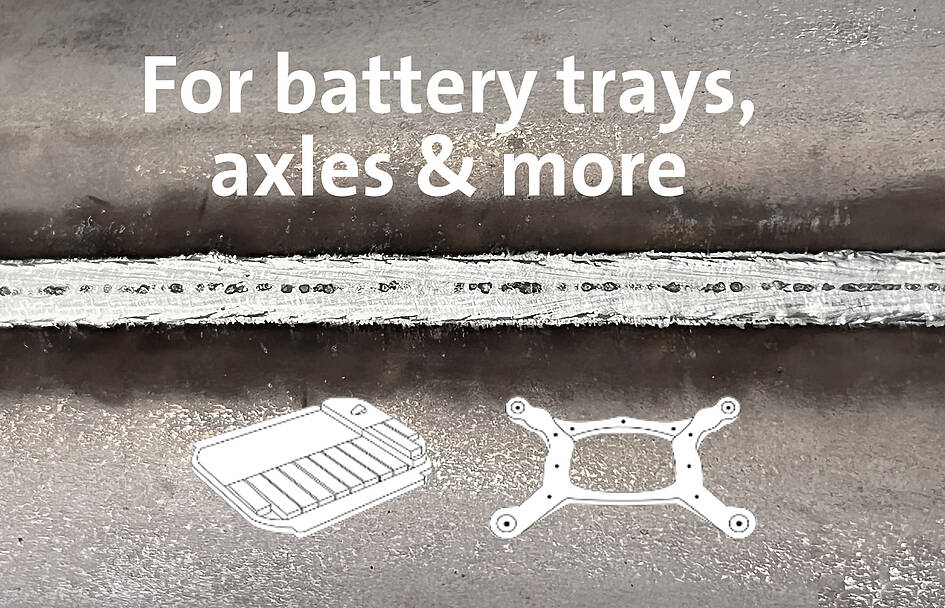

Laser + GMAW =

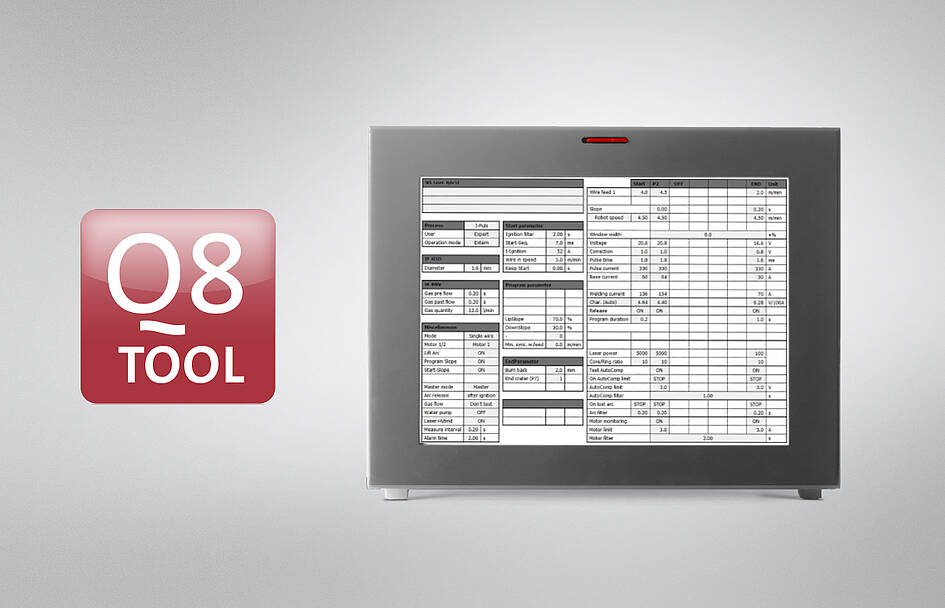

Welding speed: up to 400 cm/min

Heat input per unit length: 223 J/mm

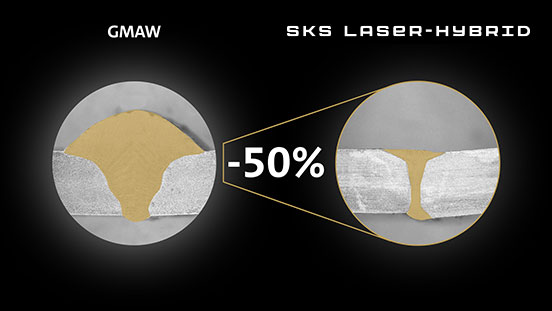

50% less filler material

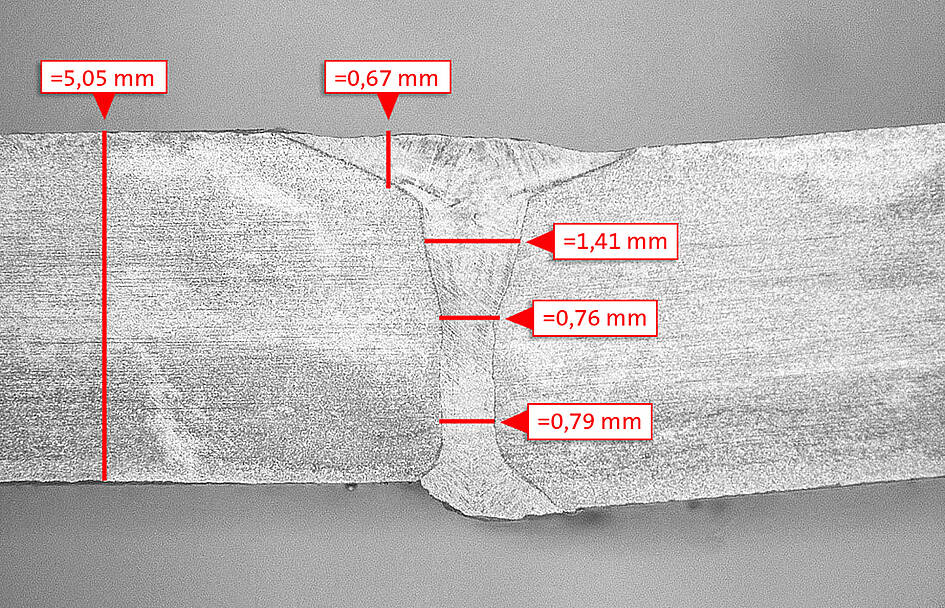

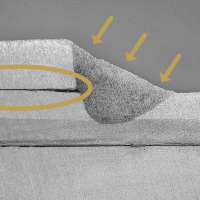

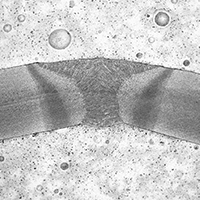

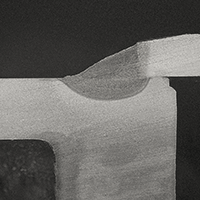

Low seam rise / integrated gap bridging

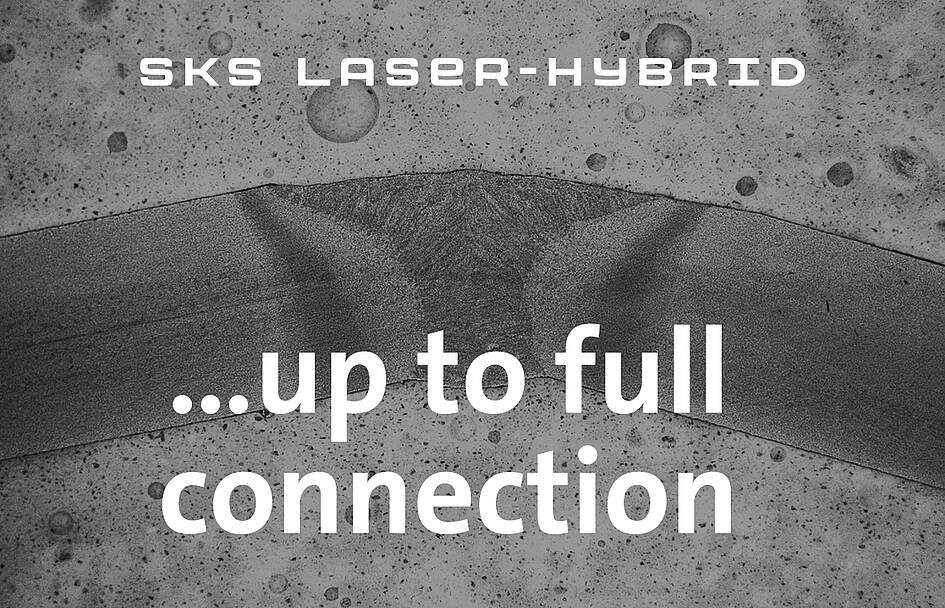

Deeper penetration up to full connection

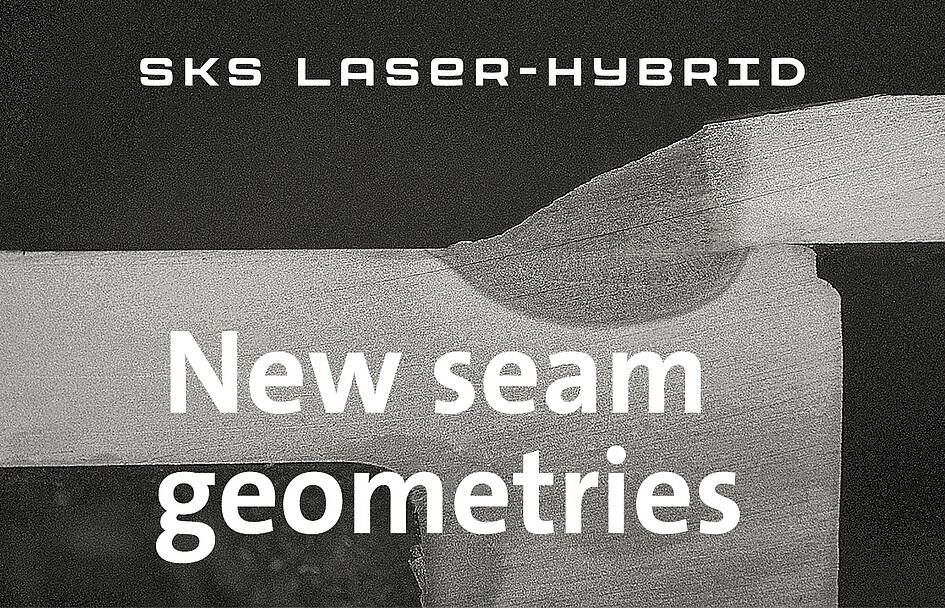

New seam geometries

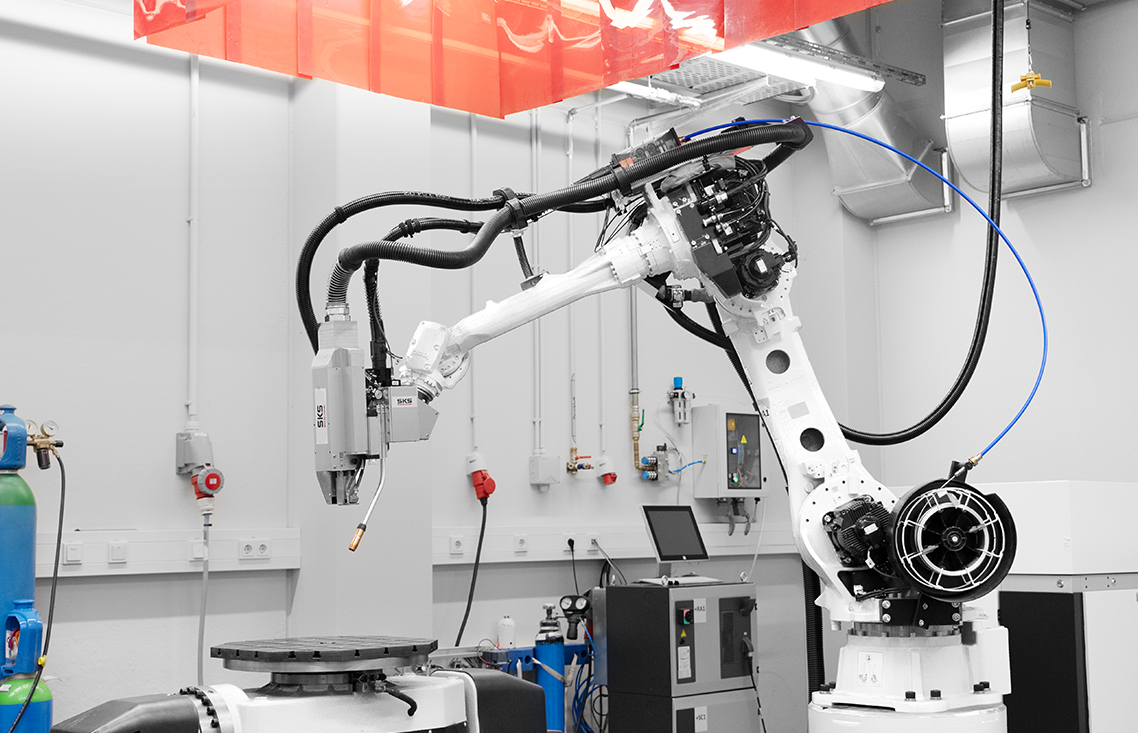

For all commonly used robot types

Weight:26.00 kg

Max. Power:420 A – 60 % duty cycle (GMAW)

Wire Diameter:0.8 – 1.6 mm

TCP Accuracy:± 0.2 mm