MMT-X:

Mechanical droplet detachment with alternating welding current

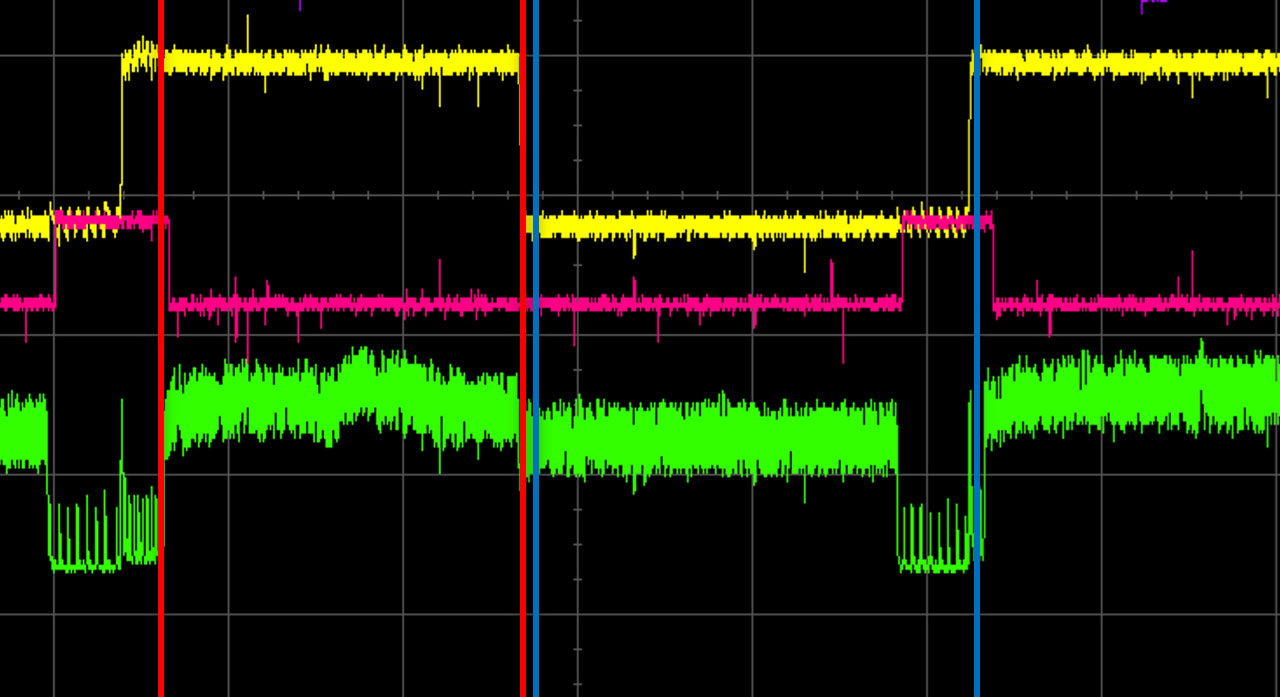

The rapid sequence of forward and backward movements of the wire electrode, combined with the increase and decrease of the welding current, creates an alternating pattern of arc phases and short circuits.

When a short circuit is detected, the wire electrode is retracted and a time-controlled high-current phase is activated. This dissolves the short circuit and enables the targeted transfer of a molten droplet into the weld pool.

The arc is then reignited, forming a new molten droplet at the wire tip and heating the component -resulting in the formation of a weld pool. Once the preset arc length is reached, the wire retraction ends and the feed direction switches back to forward movement. After the high-current phase expires, the welding current is reduced to facilitate droplet transfer into the weld pool while minimizing heat input into the component.

As soon as the droplet touches the weld pool, a short circuit occurs and the arc extinguishes. With the reversal of the wire feed direction and renewed increase of the welding current, the next droplet detaches - repeating the sequence of droplet formation, transport, and transfer.

This might also interest you