Dual Wire 2.0 Process:

Cost savings through speed

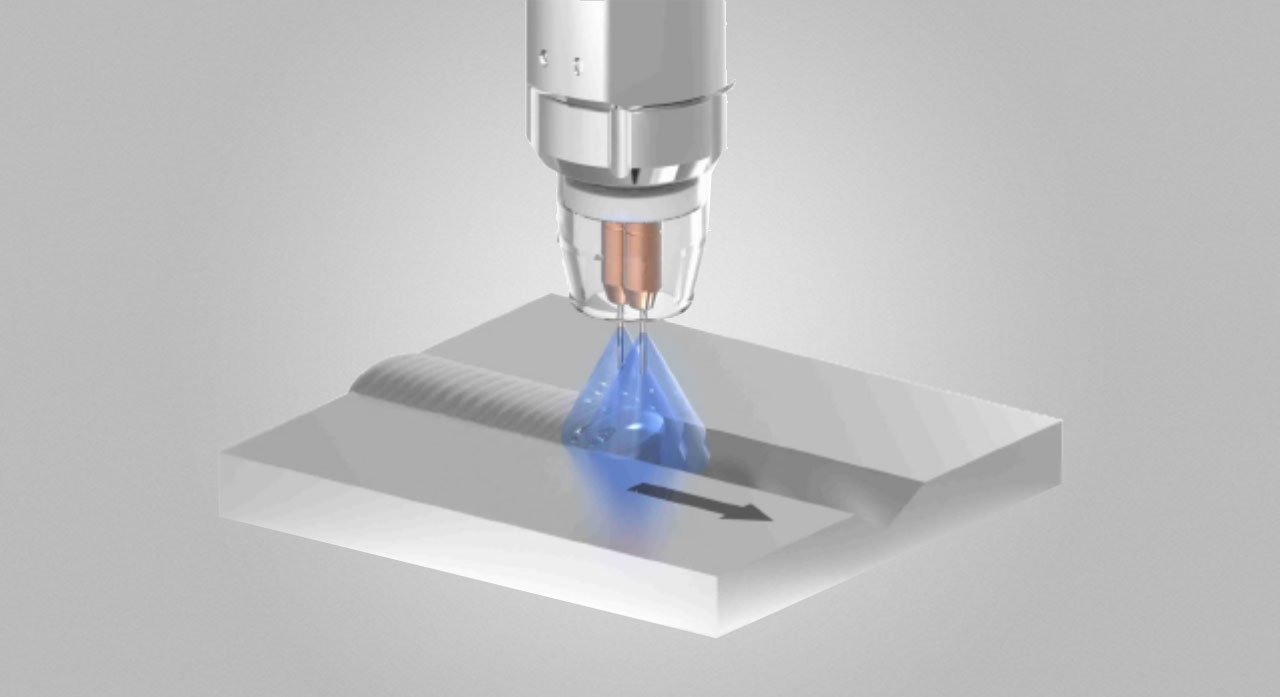

To increase productivity, more and more efforts are being made today to minimize process times. One possibility for this is the use of fully mechanized multi-wire welding processes such as Dual Wire 2.0, which can often double the welding speed. Based on SKS standard components, two power sources are connected to form a common unit, two separate wire feed systems convey the wire electrodes to the special dual wire torch system and into the welding process.

The round design of the gas nozzle allows very good accessibility, even in narrow installation spaces. Quick changes of the welding direction or single-wire applications can be implemented very easily by job-based parameter switching. The standard system components allow a wide range of application options, even the extension of a single-wire system to a dual-wire system is possible at any time.

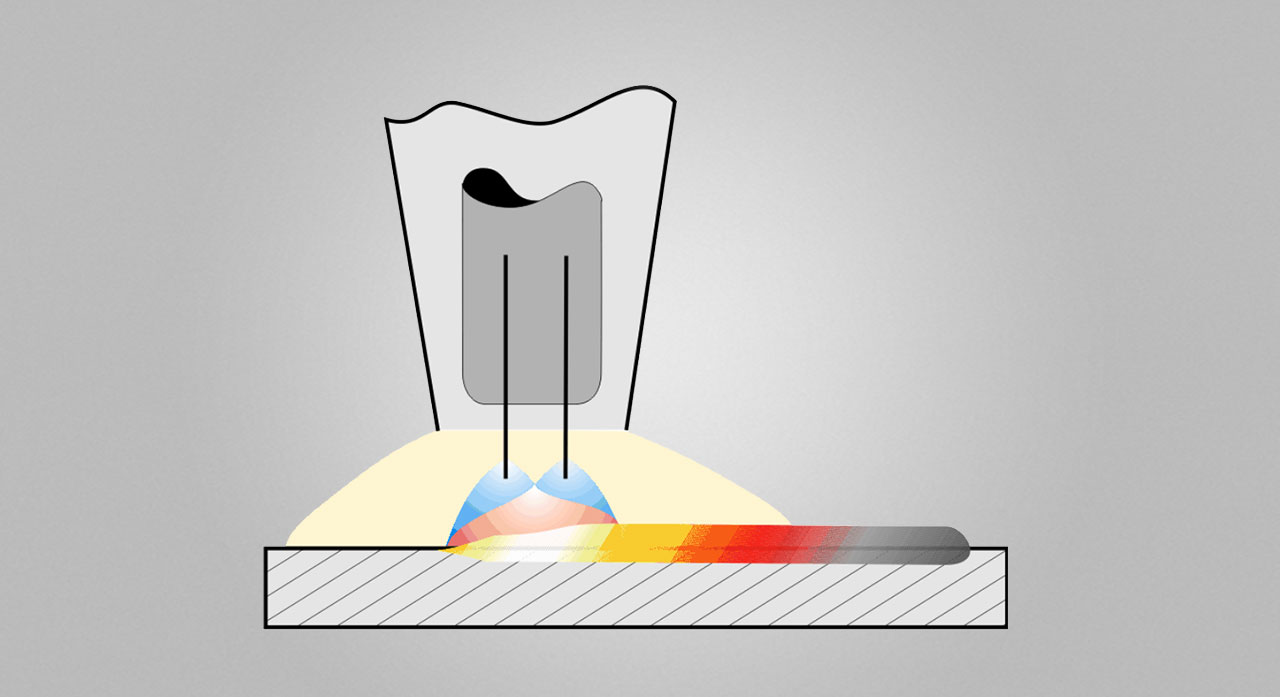

Due to the common potential and the parallel arrangement of the contact tubes, the dual-wire process is comparable in its mode of operation to a normal single-wire process. By means of pulse processes such as I-pulse or KF-pulse, two filler wires are melted in one arc and transferred to the common weld pool without using short circuits. Compared to the single-wire process, the arc burns with only slightly increased welding voltage on a larger burning surface due to the constant distance between the two wires. As the wires are arranged one behind the other, they create an oval weld pool with high arc stability. All this enables a significant increase in heat input and a higher deposition rate and thus a significant increase in welding speed – and with reduced heat input per unit length in most cases.

Special features – Dual Wire 2.0 process

- very high deposition rate

- very high welding speed

- reduction of the heat input per unit length

- single-wire or dual-wire process possible

- simple system extension from existing single-wire system

- easy accessibility due to slim, round gas nozzle

Application example – fillet weld

S500MC 15 mm (2x)

DW-I-pulse

V = 80 cm/min

Pendulum motion 2 Hz

Video: Welding with the SKS Dual Wire 2.0 welding process

This might also interest you