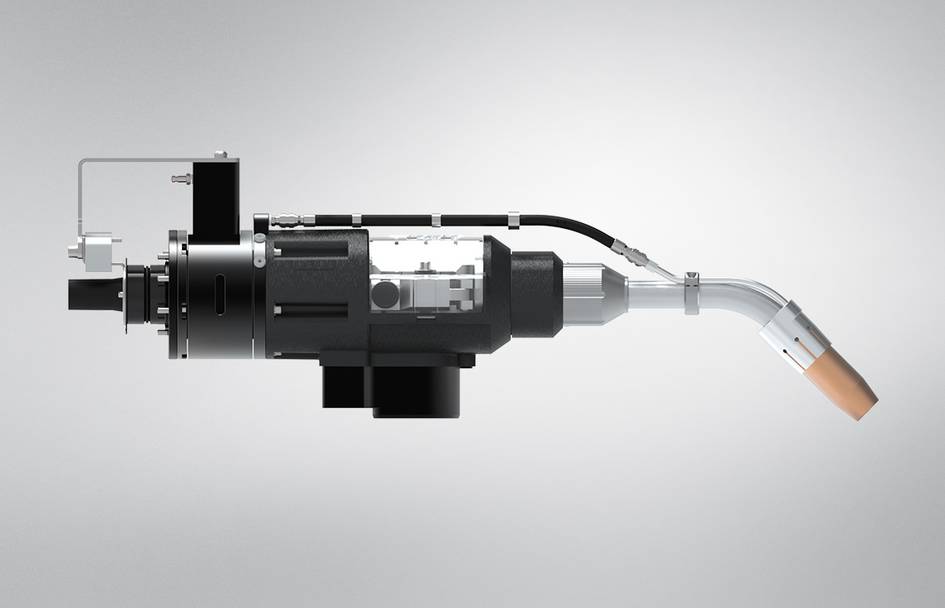

Frontpull 8i Lite water-cooled Features

Yes No

Aluminum Low-alloy steels High-alloy steels Copper alloys Nickel-based materials

microMIG & microMIG-cc KF-pulse Pulse MIG-brazing GMAW/MIG

Air Water

Yes

No

Aluminum

Low-alloy steels

High-alloy steels

Copper alloys

Nickel-based materials

microMIG & microMIG-cc

KF-pulse

Pulse

MIG-brazing

GMAW/MIG

Air

Water

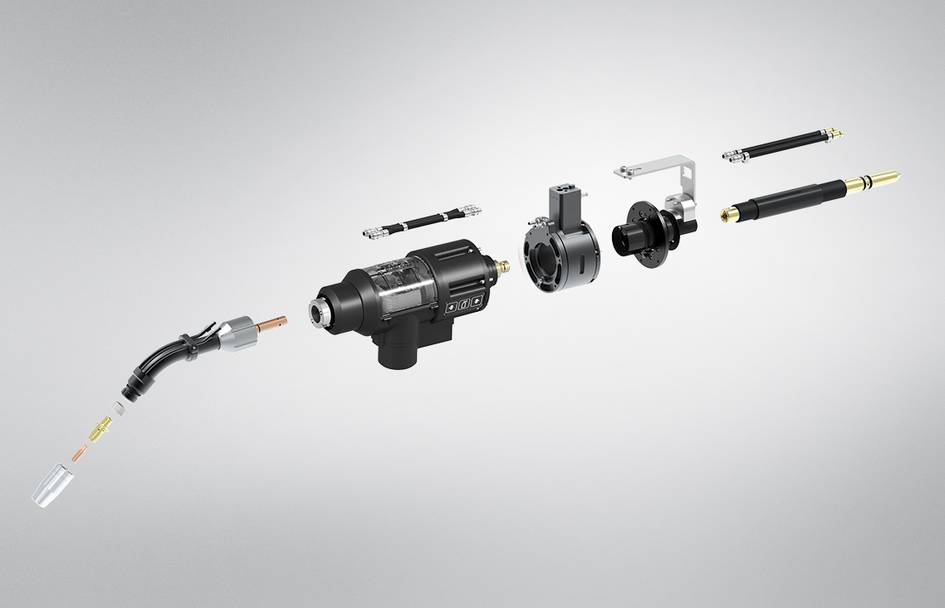

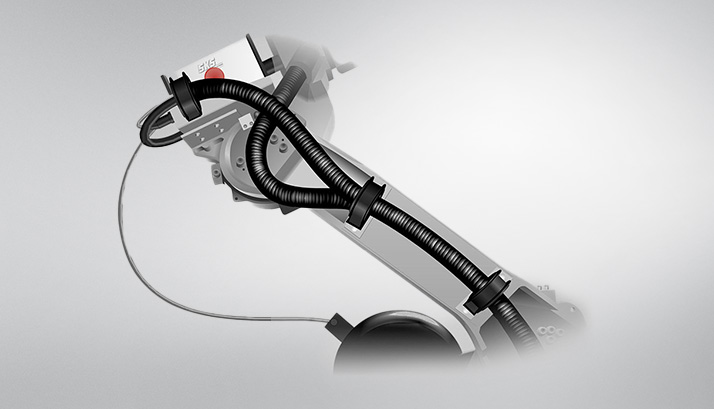

For all commonly used robot types

Weight:3.00 kg

Max. Power:420 A – 60 % duty cycle

Wire Diameter:0.8 – 1.6 mm

TCP Accuracy:± 0.20 (at 400 mm)