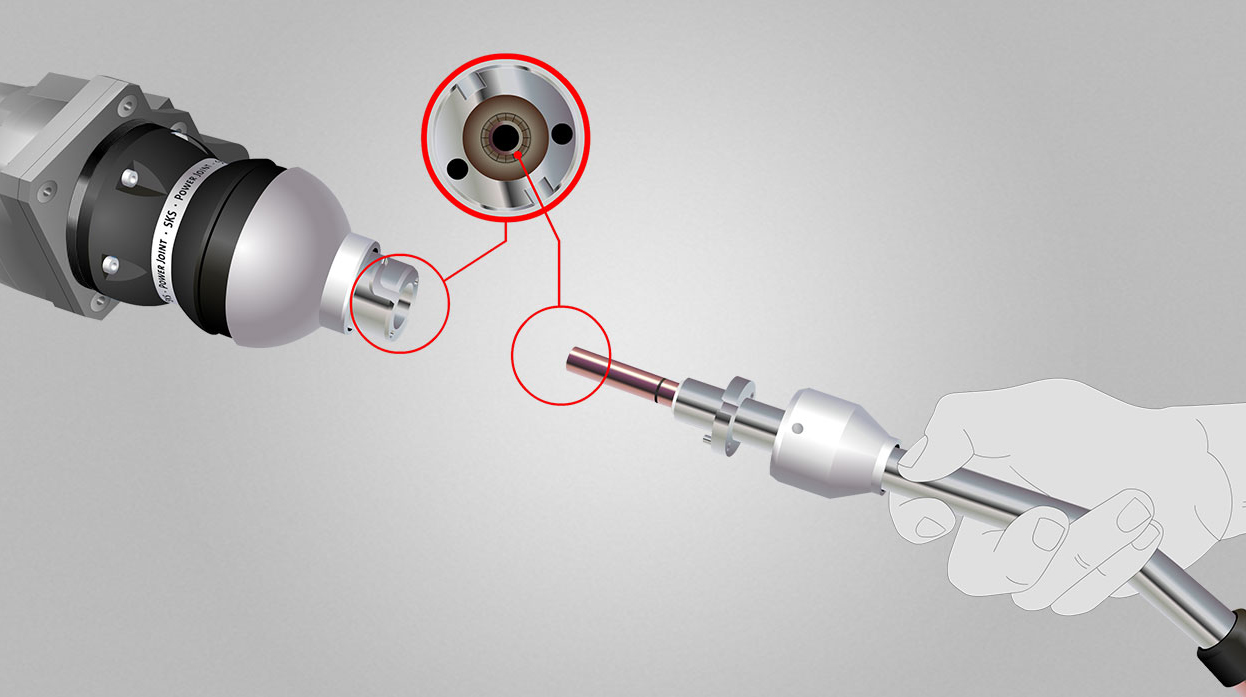

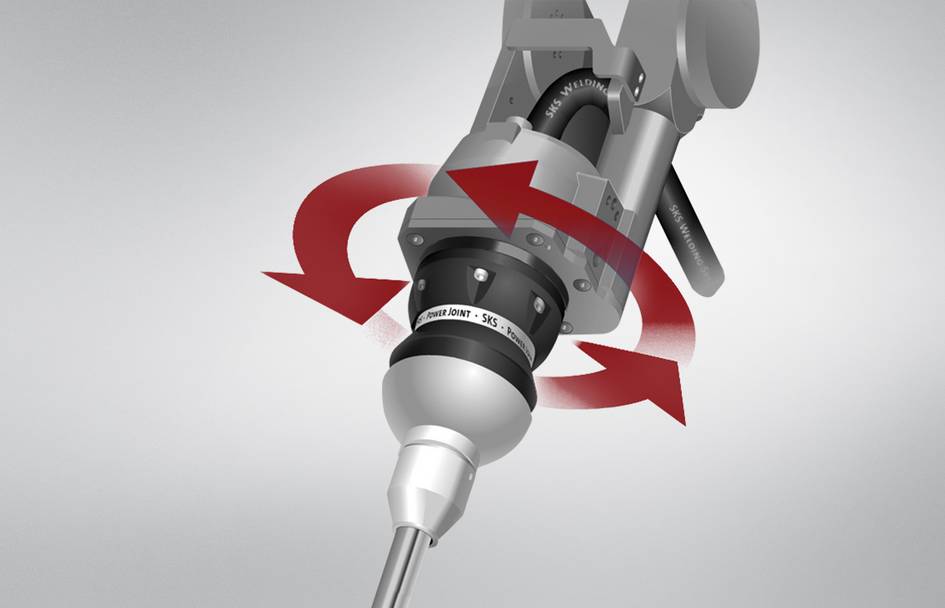

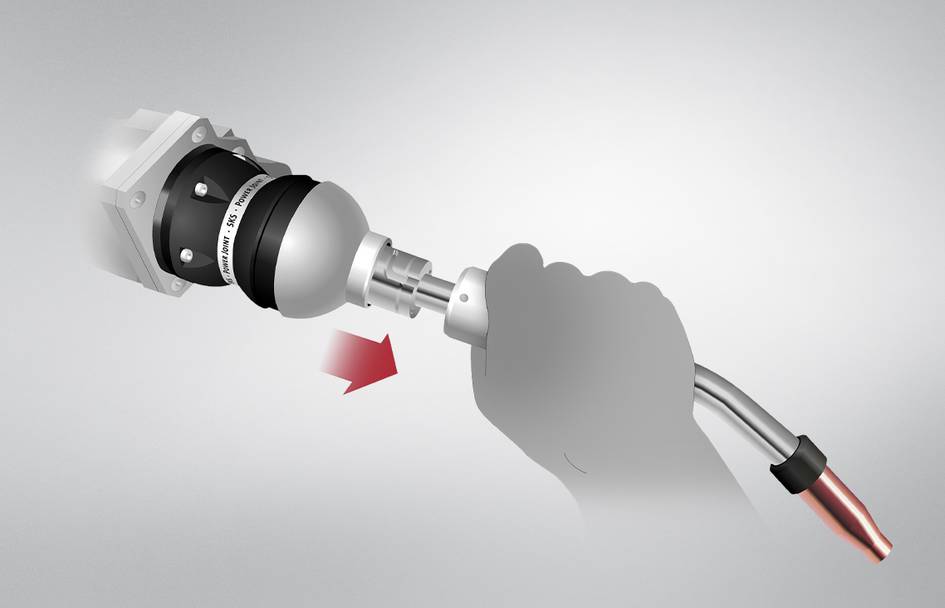

The Power Joint torch system perfects the interaction between welding machines and robots with an internal torch cable. The rotating joint of the Power Joint features unlimited rotation (beyond 360°, no stop) and supports the transmission of power, gas, air and wire. Compared to competitive solutions, the Power Joint can endlessly rotate about its own axis in either direction.

Another advantage: Disconnecting the torch cable from the torch movements eliminates any torsional strain on the cable thereby significantly increasing the lifetime of the torch cable. Consequently, the use of the Power Joint also increases the availability of the overall plant.

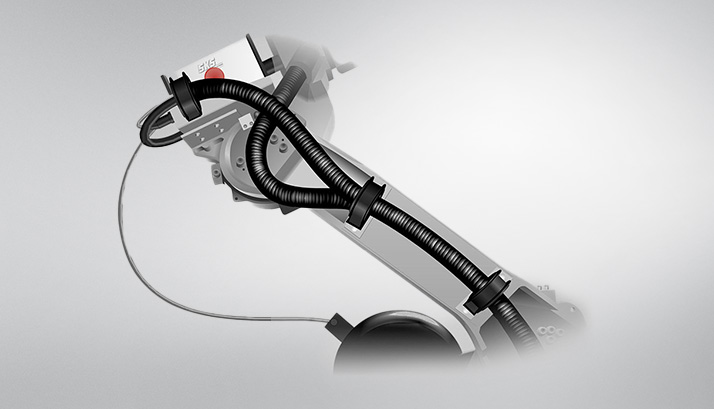

Thanks to its low weight and innovative design, the Power Joint helps the robot to make full use of its maneuverability. Time-consuming reversing of the hand axis or limitations of the articulation axis are a thing of the past – the robot can reach any desired point by the shortest possible path. This also leads to considerably less effort during the teaching of the robot.