Q4 Features

Synchroweld NWDE (Traceability Function) RWDE

GMAW/MIG I-Pulse U-Pulse KF-Pulse microMIG

microMIG-cc TIG-DC TIG-Pulse Dual wire

Touch Panel Keys / LCD

Ethernet SPW-Bus RS232 USB

Q8Tool VNC-Client

Synchroweld

NWDE (Traceability Function)

RWDE

GMAW/MIG

I-Pulse

U-Pulse

KF-Pulse

microMIG

microMIG-cc

TIG-DC

TIG-Pulse

Dual wire

Touch Panel

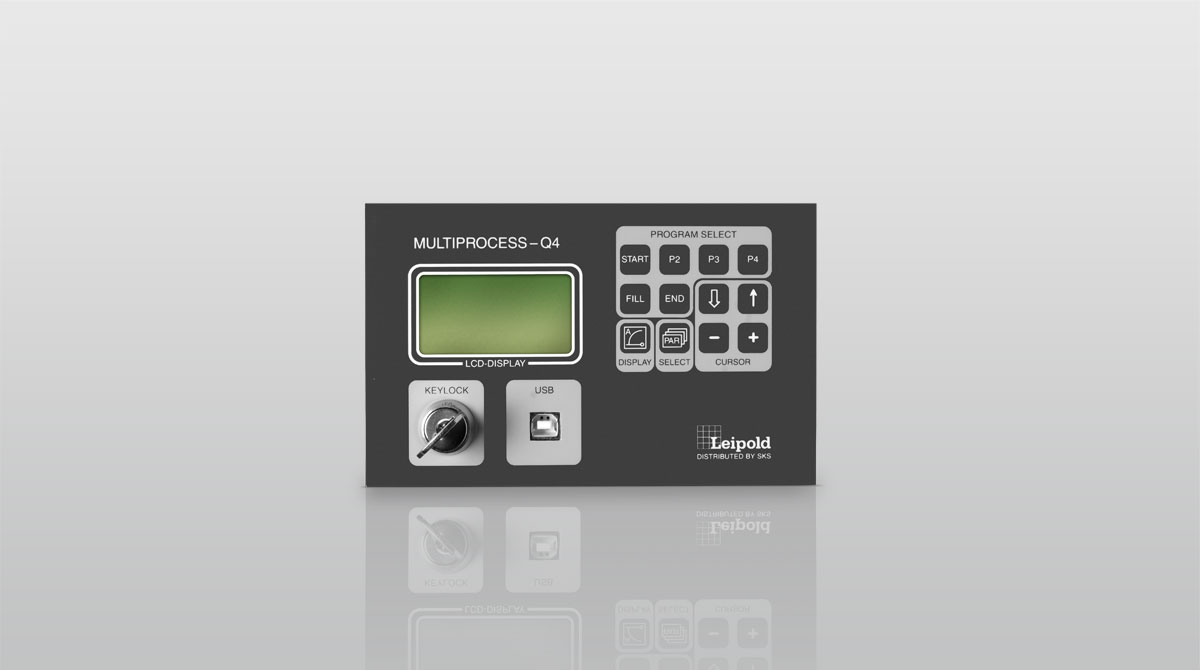

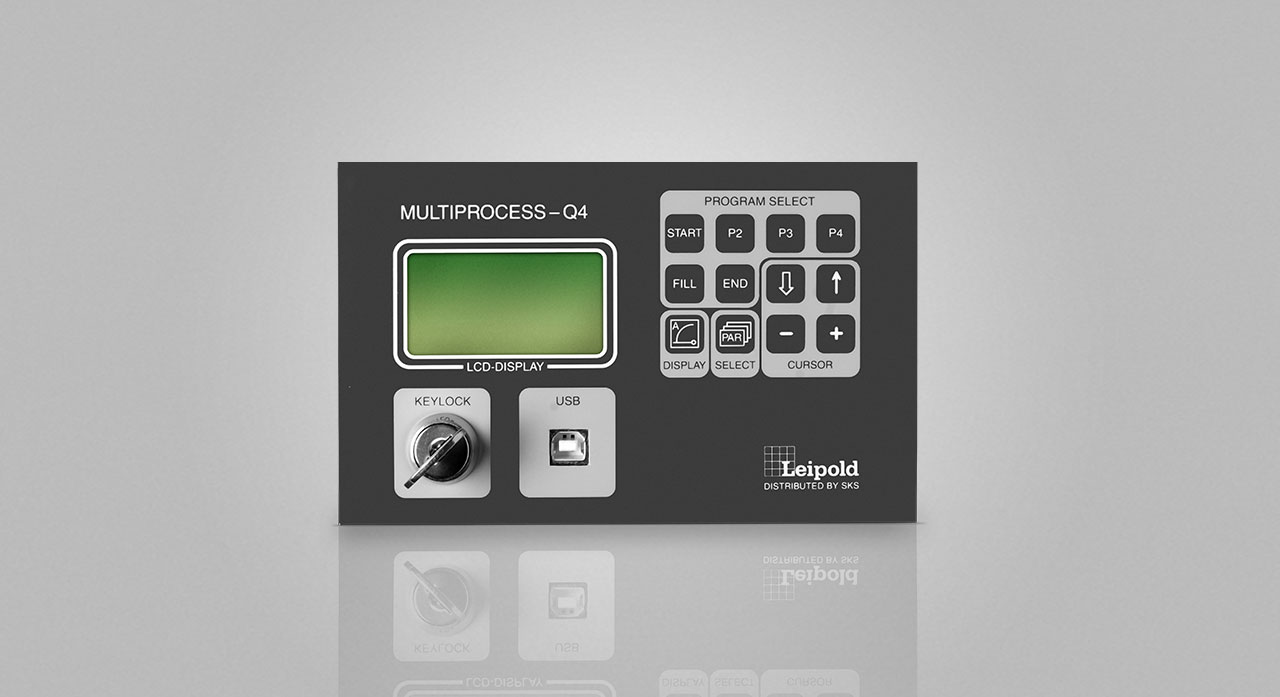

Keys / LCD

Ethernet

SPW-Bus

RS232

USB

Q8Tool

VNC-Client

186

Weight:integrated into the power source

Dimensions (l / w / h):integrated into the power source