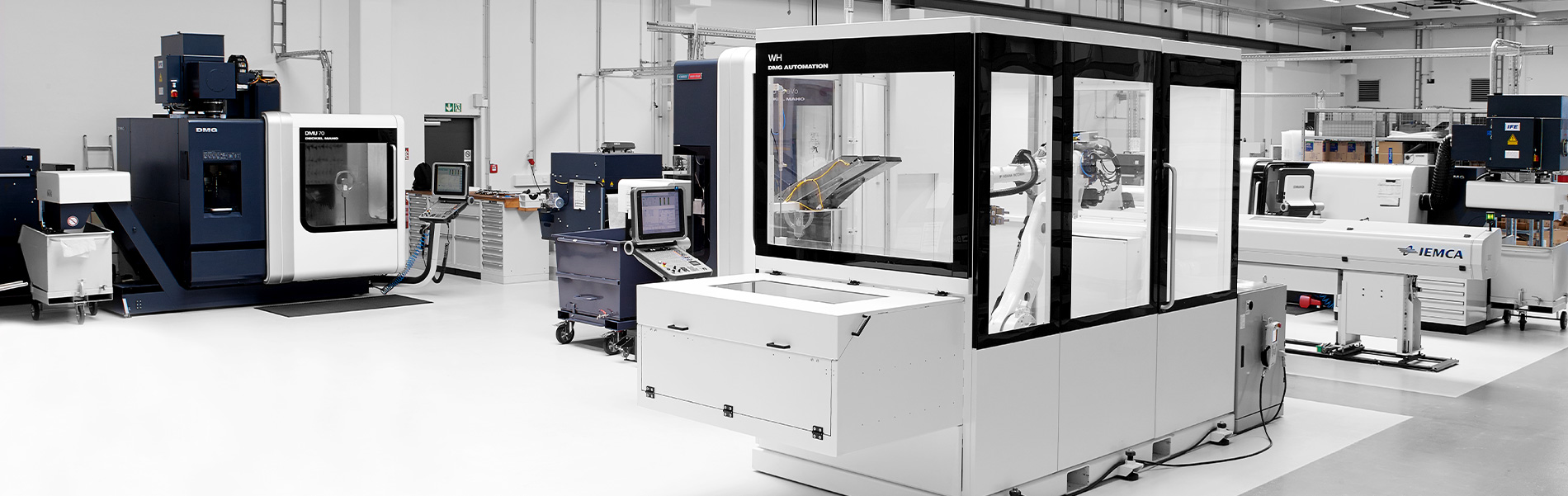

Production

Precision – a premise for quality

The result of highest precision: Consistently optimized and reproducible welding results lead to reduced periods of inactivity and therefore also to reduced costly downtimes. Precision is a question of the right details – and an important part of our company culture. Therefore, we take up the challenge to solve all issues that may occur in the course of our development and production activities to support the quality of welding machines and welding torches in an ideal way.

Highest quality for the best possible results – down to the smallest detail: this ensures that all original SKS parts are perfectly matched to the specific requirements of individual welding applications. Cross-functional dimensions and tolerances are often only known to the developer and manufacturer of a product. A typical example: The current transition between the torch neck, retaining head and contact tip is critical for an optimized performance and the service life of the whole welding torch system. For this reason, retaining heads, contact tips and torch necks, in strict accordance with the TCP accuracy requirements are designed and produced in-house.

An additional service: We also offer our customers the production of special parts, prototypes and low-volume production.

Quality is reflected in every detail.