„With our product developments, we see ourselves as innovator in the industry. The pursuit of the perfect technological solution is deeply rooted in our company – and an essential part of the SKS corporate culture. We always choose to go the extra mile to offer the best and most sustainable welding solutions in the market. This is the driving force behind all we do.“Thomas Klein, Managing Director SKS

Research & Development

Wanting more – achieving the best

Our research and development work is based on two different impulses: The current requirements of the market for higher availability and productivity combined with a reduction in costs – and our own ambition as developers to extend the technological possibilities of automated arc welding.

SKS understands its development work as a continuous optimization of systems and processes that considers both current challenges and future demand.

The foundation of this work is the intensive interchange with our customers, partners, renowned robot manufacturers and research institutes.

Based on this process, SKS develops high-quality products with added value that make welding processes more economical and keep their application, installation and maintenance efforts low and simple.

Because really new concepts are concepts that create advantages.

Capture the essence

Reduce to the basics –

continuous extension of possibilities

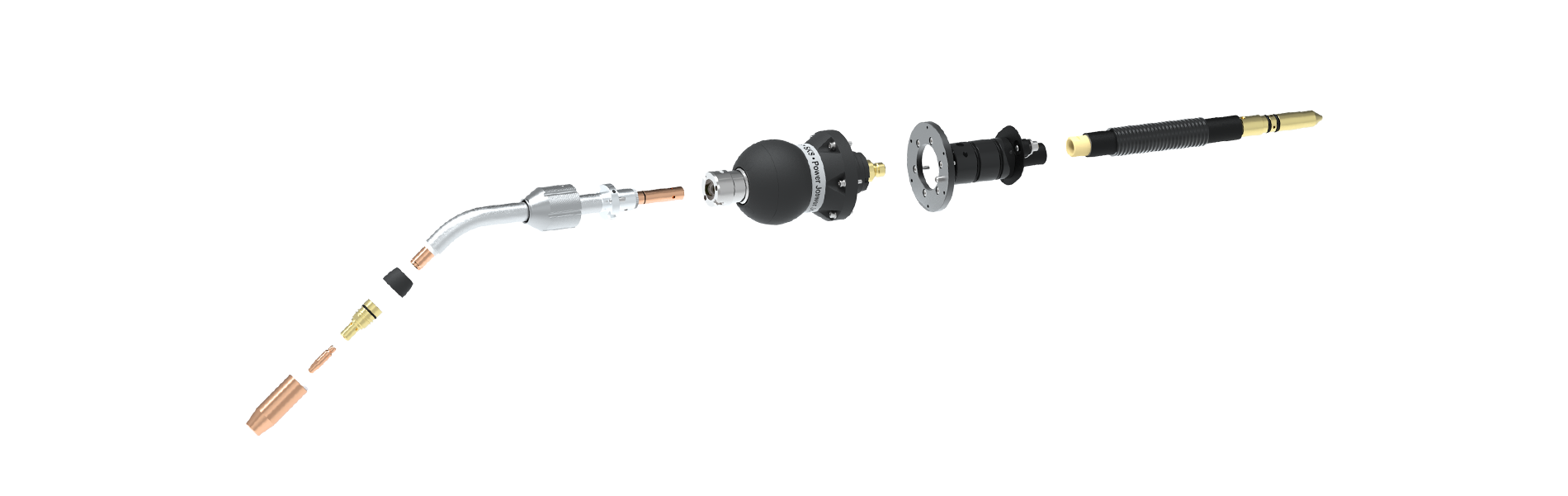

Reduction to the basics is a main principle of our development activities. This means, among other things, that sources of interference in processes or systems are eliminated through development or replaced by innovative new systems. By applying this principle, SKS offered their customers a significant optimization potential with the introduction of the air-cooled robot welding torch in Europe at the end of the 1990's.

Air instead of water – a little revolution – means: No hoses, no leaks, no damage from leaking moisture, and – of course – no expensive equipment for water cooling. The biggest savings were, however, achieved by the elimination of the extensive maintenance requirements and the related logistics.

Based on the foregoing, we apply the following principles in the development of processes and welding machines: All new developments must be compatible with the core of our welding machine (weld process control, power source, robot interface, and wire feeder). And: The process reliability of the overall system must not be affected by customized solutions.

Because sometimes less is more.