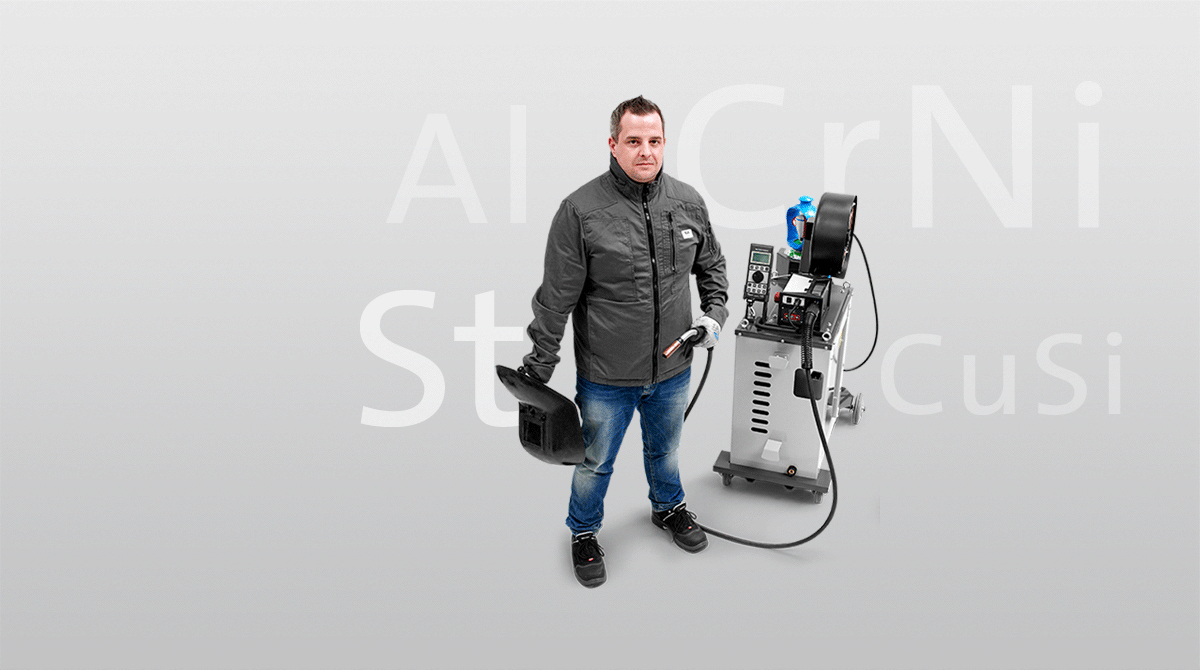

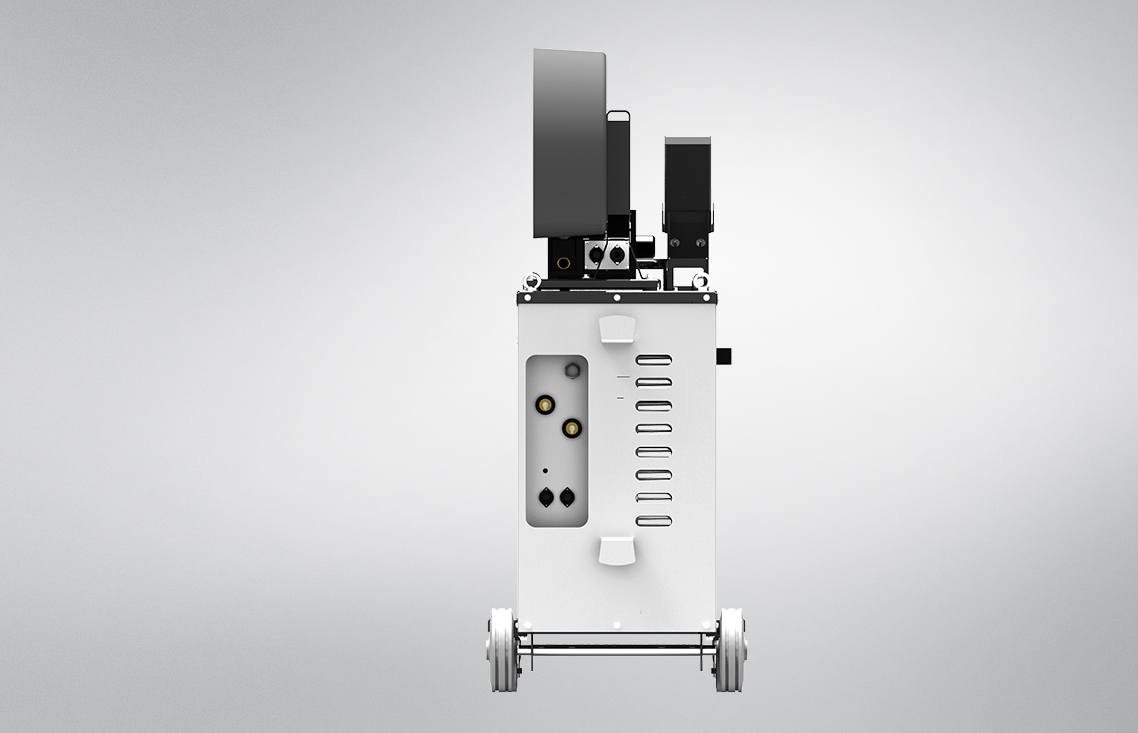

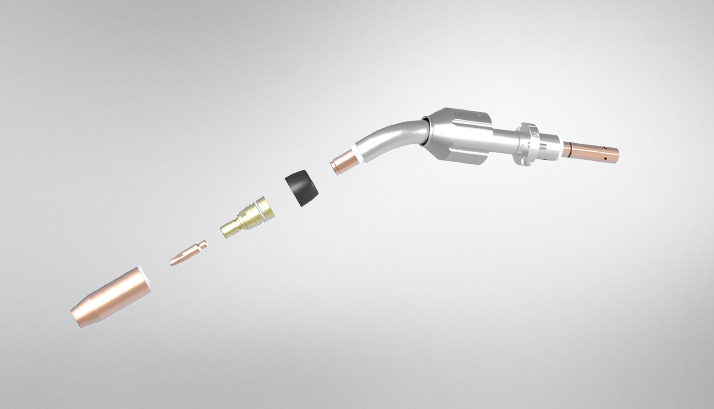

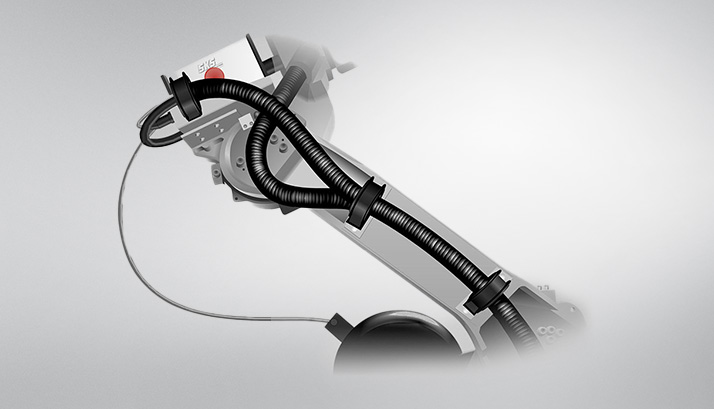

The ‘SAM mobile’ Weld Package consists of a trolley holding the PF6 Power Feeder, LSQ power source, and a fixture for the Q1 controller. The scope of delivery also includes the Q1Tool software. The trolley is prepared for wire feeding directly from the drum, but can be additionally equipped with a wire spool holder. So, this mobile configuration can be flexibly configured and used. The simplified design using SKS standard components facilitates maintenance and installation. Furthermore, the operating concept is based on SKS standard controls, so that the training effort required to use the SAM is very low. The advantages of using robotic welding technology for manual welding are clear: The high-quality processing of the components ensure a very long service life. The wear parts are standard wear parts that were developed for the high demands of the use on robots.

With the use of standard robot components, a lower variety of parts is achieved, which minimizes storage complexity. In addition, the support and monitoring functions of the robotic applications are now available for manual welding. The available welding processes and material characteristics correspond to those of the robot welding system and ensure optimum joining of a wide range of materials. The Q1Tool software, which is included free of charge in the scope of delivery, allows easy administration of the hand control via a standard PC or notebook (reading, writing and saving of welding parameters and documentation features). The manual control unit can be programmed with predefinable welding parameters – independently of the welding machine. With the simple duplication of the predefined welding parameters, manual workstations can be set up quickly and reliably.