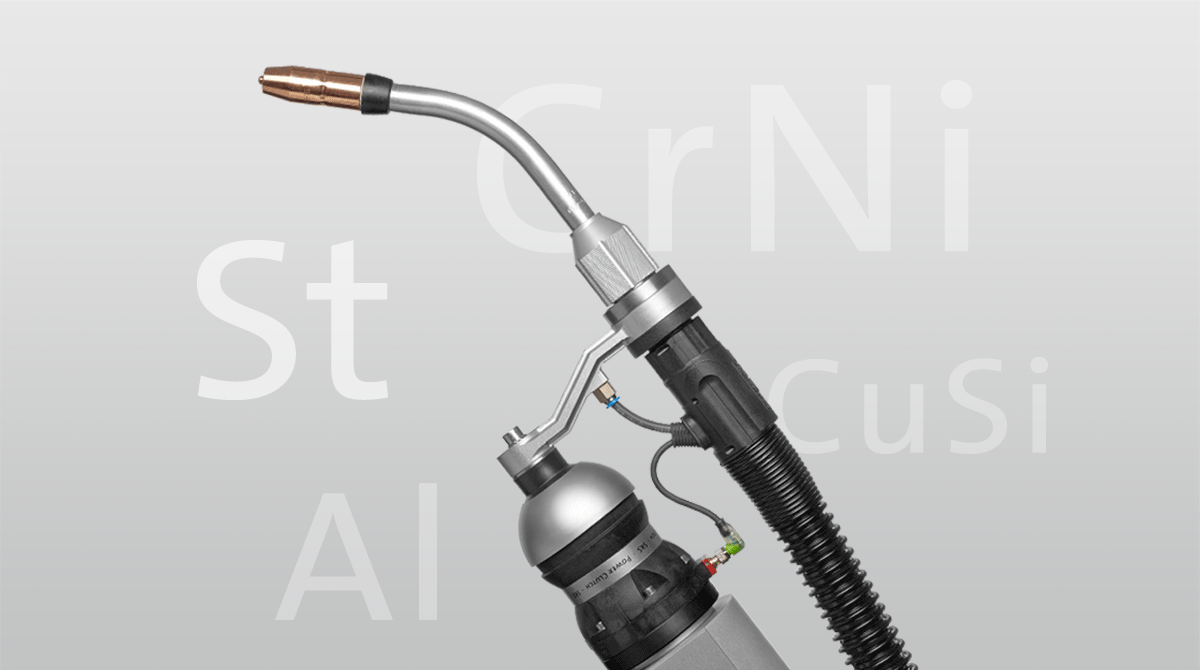

Power Clutch:

For all standard welding tasks

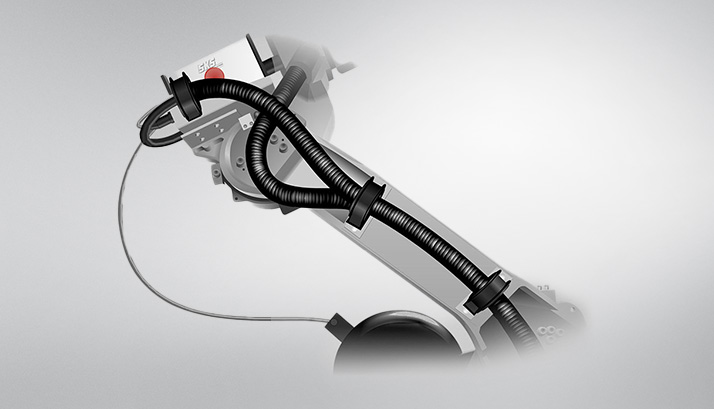

The Power Clutch torch system perfects the interaction of welding machines and robots with an external torch cable. It uses the same technologies and wear parts that have proven themselves in large-scale industrial applications as other tried-and-tested torches of the modular SKS torch series.

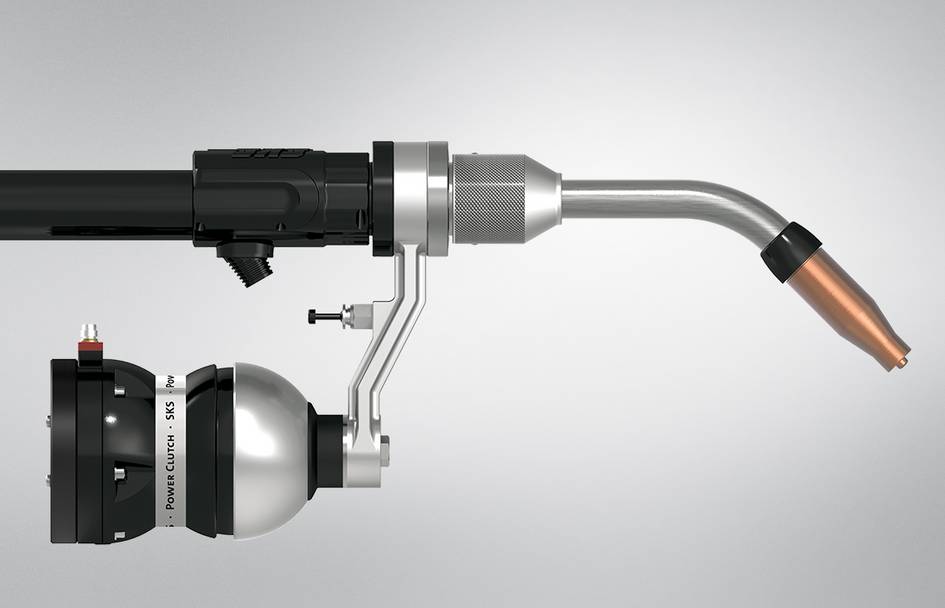

The internal spring system of the Power Clutch switch-off box returns the torch neck to its original position (TCP) with high accuracy after a deflection. The large cross-section (72 mm²) of the coaxial torch cable and the contacting in the torch holder optimized with high-current laminations ensure low-loss transmission of the welding current and shielding gas.

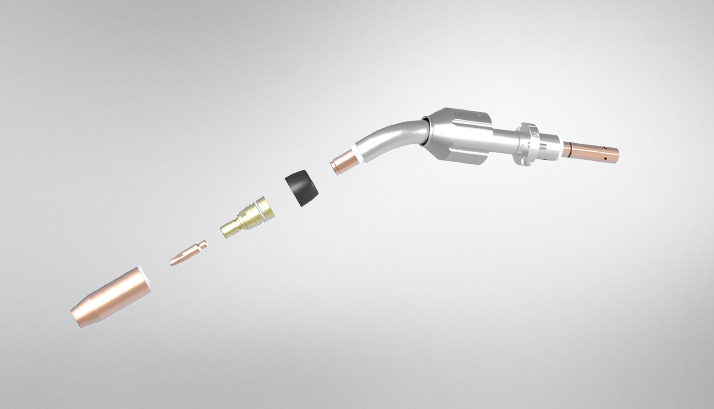

SKS torch necks can be changed quickly and precisely on the Power Clutch using the innovative bayonet quick-lock system. For the tool-free change of the torch neck, a TCP of ± 0.2 mm is guaranteed. A wide range of torch necks in special designs, geometries and dimensions is available for complicated welding tasks or tasks in hard-to-reach areas.

Variable in design and supplemented by robot-specific add-on parts (connection flanges, etc.), the Power Clutch torch system provides the ideal solution for all standard welding processes and filler materials.