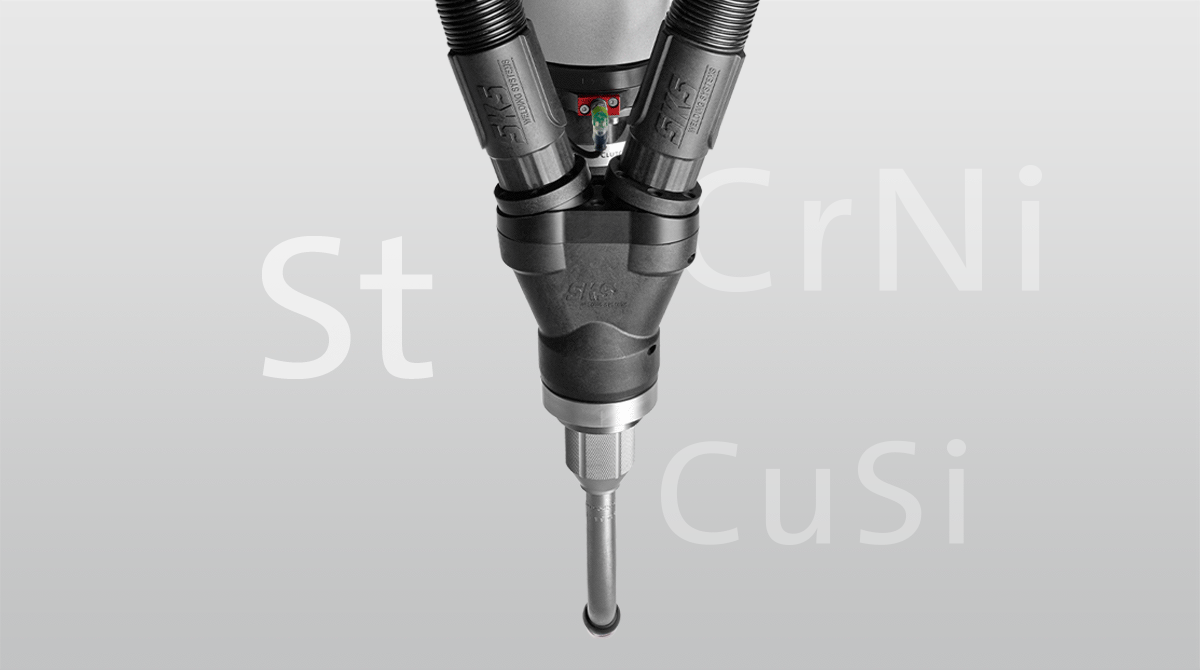

Wire Select 2.0:

Welding with two different materials with automatic wire change

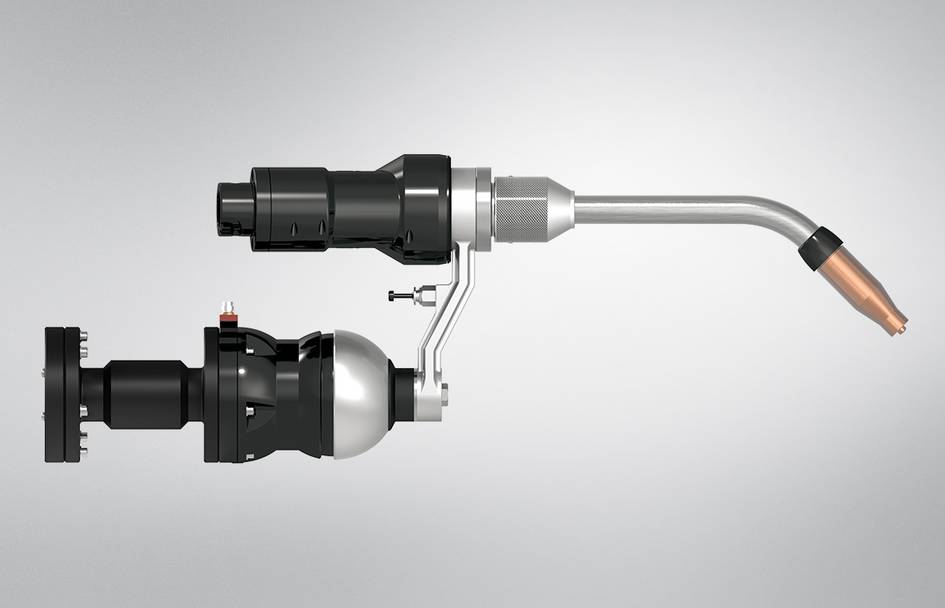

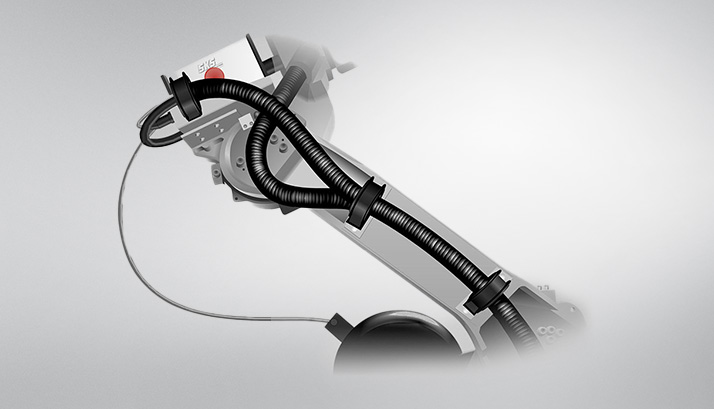

The Wire Select 2.0 welding torch allows welding with two different wires on the same workpiece – without the need to change the torch or supply lines. With only one power source, one controller, one torch, and two wire feeders, you are able to complete your welding task using two different weld fillers, two different gases, and different processes (e.g. Pulse welding and MIG brazing) in a single production unit. Long and inefficient changeover times required to change the weld filler are eliminated.

With the SKS Wire Select 2.0 welding torch two different materials can be welded on one workpiece

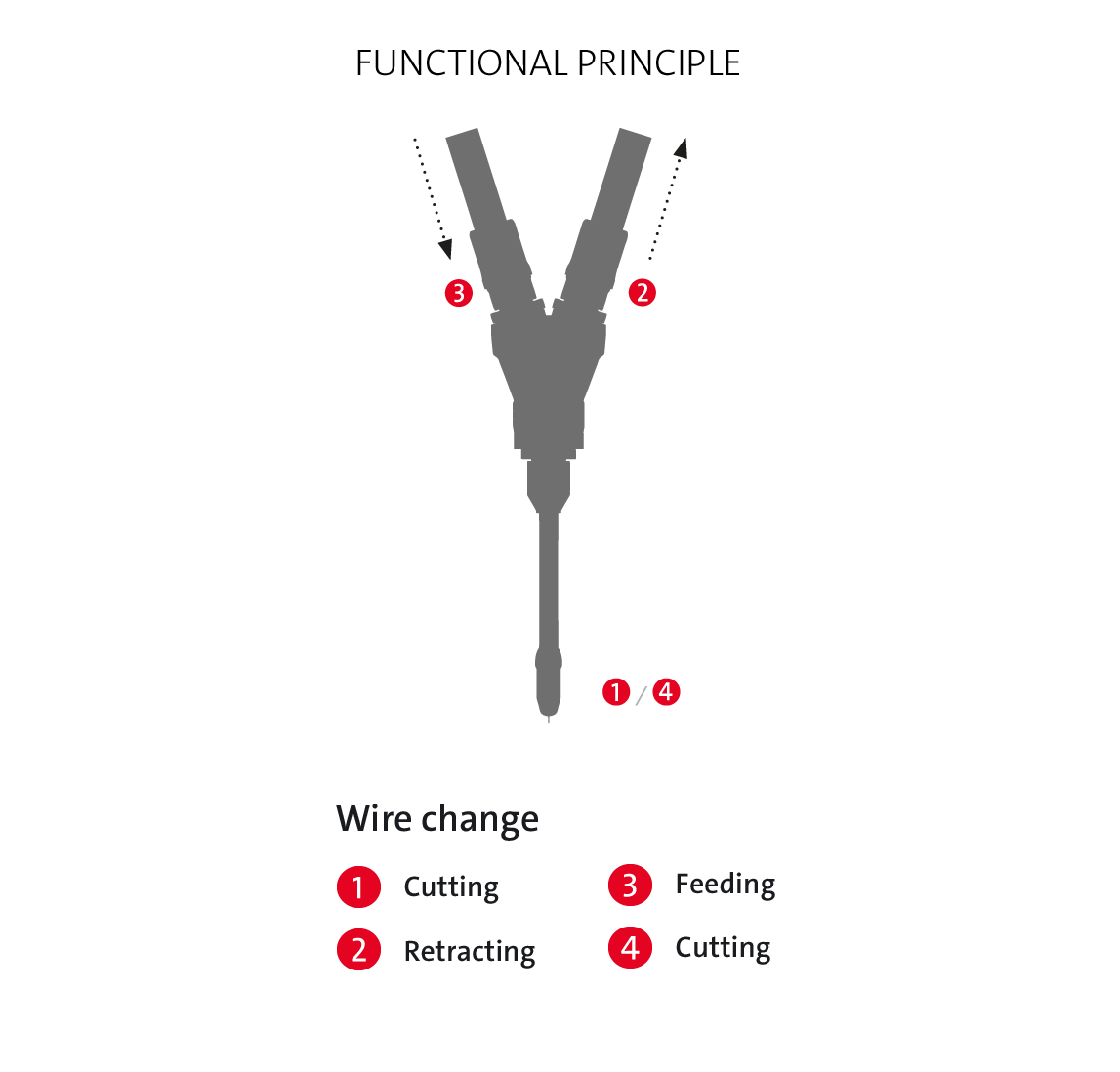

The wire change is performed by automated retraction of one wire and automated threading of the other – within just a few seconds. In addition to the time/cost savings in operation, this concept ensures lower investment costs compared to conventional methods, as only one welding system and the Wire Select 2.0 torch system are required.

Application examples for the SKS Wire Select 2.0 welding torch

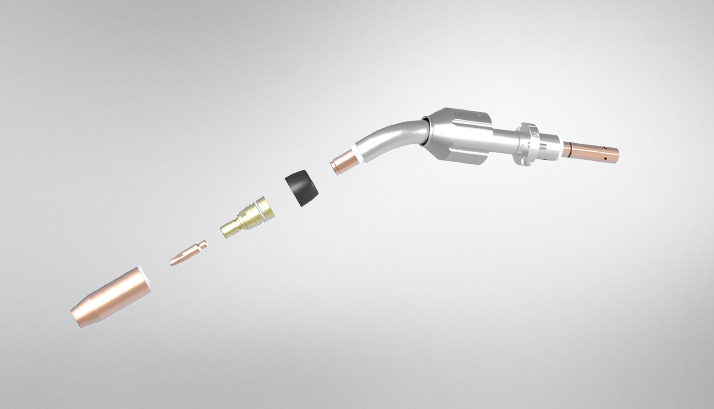

Widely varying temperature conditions on a component, e.g. at the hot and cold ends of an exhaust system, require different materials and thus correspondingly adapted weld fillers. Instead of changing them by means of a torch changing system or a second robot with welding equipment a Wire Select 2.0 welding torch is all it takes. Within a few seconds, the automatic wire change is made in four short steps: cut off, withdraw, feed, cut off. The torch neck from SKS's standard portfolio ensures the familiar good accessibility to the welding area. Process combinations are solved by the Wire Select 2.0 in the same way. For example, users can weld thin steel piping of hydraulic brake systems and then braze the brackets. Also different gases can be used for each wire electrode, depending on the process or material. Efficiency advantages of the Wire Select 2.0 result both in comparison with a torch changing system and with the use of a second robot. The capital expenditure required for both alternatives is significantly higher. In addition, there are indirect financial expenses and non-productive time. The changeover time for a torch exchange system is much longer than with the Wire Select 2.0. Solutions with two robots require more space in the production floor, sometimes additional clamping devices or positioning and handling effort.